High-temperature sulfur-containing nitrogen-containing flue gas waste heat multi-effect distillation seawater desalination system

A multi-effect distillation, flue gas waste heat technology, applied in seawater treatment, water/sewage treatment, general water supply saving, etc., can solve the problems of easy adhesion of scales, low temperature acid dew corrosion, etc., to reduce waste heat discharge and corrosion resistance. The effect of strengthening and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

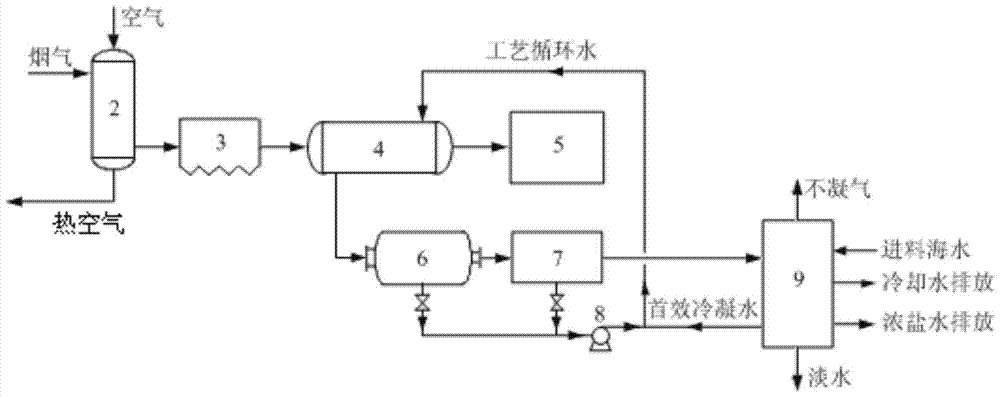

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] High-temperature sulfur-containing nitrogen-containing flue gas waste heat type multi-effect distillation seawater desalination system, see figure 1 , including economizer 2, electrostatic precipitator 3, desulfurization and denitrification device 5 and low-temperature multi-effect distillation seawater desalination device 9, also includes corrosion-resistant heat exchanger 4, circulating water flash tank 6 and gas-liquid separator 7; from the boiler The flue gas pipeline is connected to the economizer 2, and the economizer 2 is connected to the electrostatic precipitator 3, the corrosion-resistant heat exchanger 4 and the desulfurization and denitrification device 5 in turn through the pipeline; the hot water outlet of the corrosion-resistant heat exchanger 4 is connected to the circulation through the pipeline The water flash tank 6 is connected, the steam out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com