Room-temperature preparation method of early strength type polycarboxylate superplasticizer

A technology of polycarboxylic acid and water reducing agent, applied in the field of concrete admixture, can solve the problems of being unsuitable for large-scale promotion of industrial production, unsuitable for industrial production, complex production process, etc., and achieves fast growth and termination of free radicals, raw materials The effect of low price and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

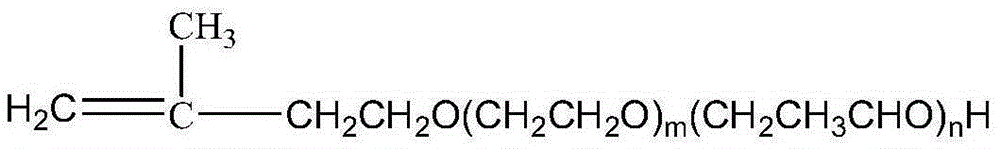

Method used

Image

Examples

Embodiment Construction

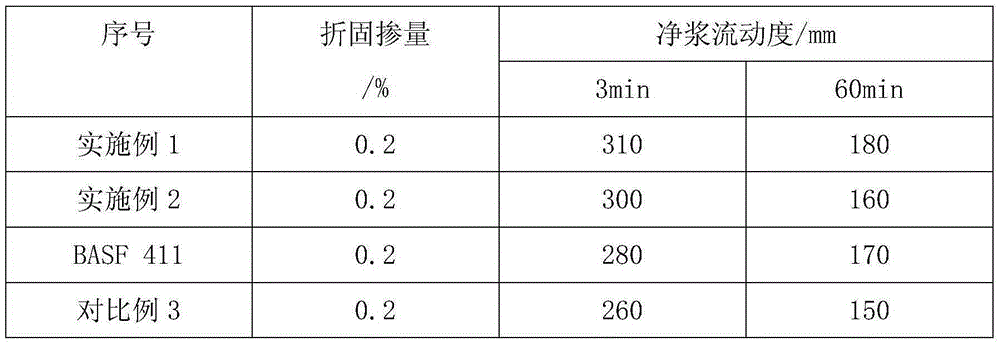

[0035] The above-mentioned normal temperature early-strength polycarboxylate superplasticizer provided by the present invention, the early-strength agent of Comparative Example 3 and the same type of products in the market are tested according to the fluidity of the clean slurry (GB / T8077-2000): using benchmark cement, according to GB / T8077-87 tests the fluidity of cement paste, and the test results are shown in Table 1 below.

[0036] Table 1 Clean pulp performance test results

[0037]

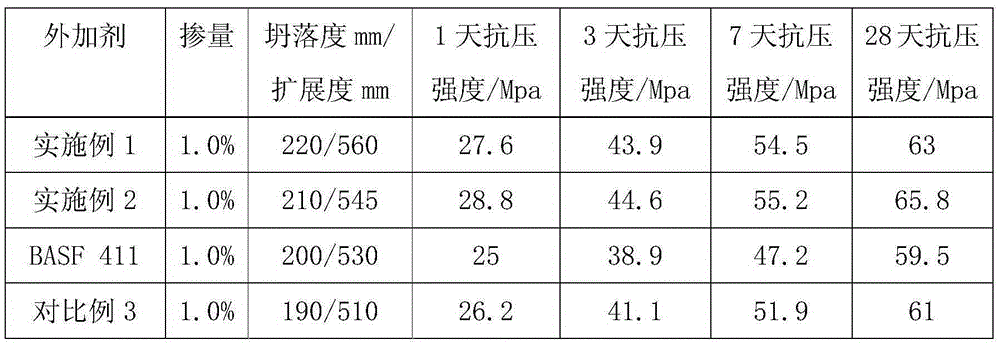

[0038] The above-mentioned normal temperature early-strength polycarboxylate water-reducer given by the present invention is compared with the early-strength agent of Comparative Example 3 and the same type of products on the market. The concrete formula is: conch PO 42.5 cement: fly ash: sand : Pebble: Water: Admixture = 547.5: 97.5: 1020: 1530: 195: 6.45. The comparison results are shown in Table 2 below.

[0039] Table 2 Concrete performance comparison results

[0040]

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com