High-breakdown-voltage GaN-based high-electron-mobility transistor

A technology of electron mobility and high breakdown voltage, applied in circuits, electrical components, semiconductor devices, etc., to solve the problem of low breakdown voltage and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

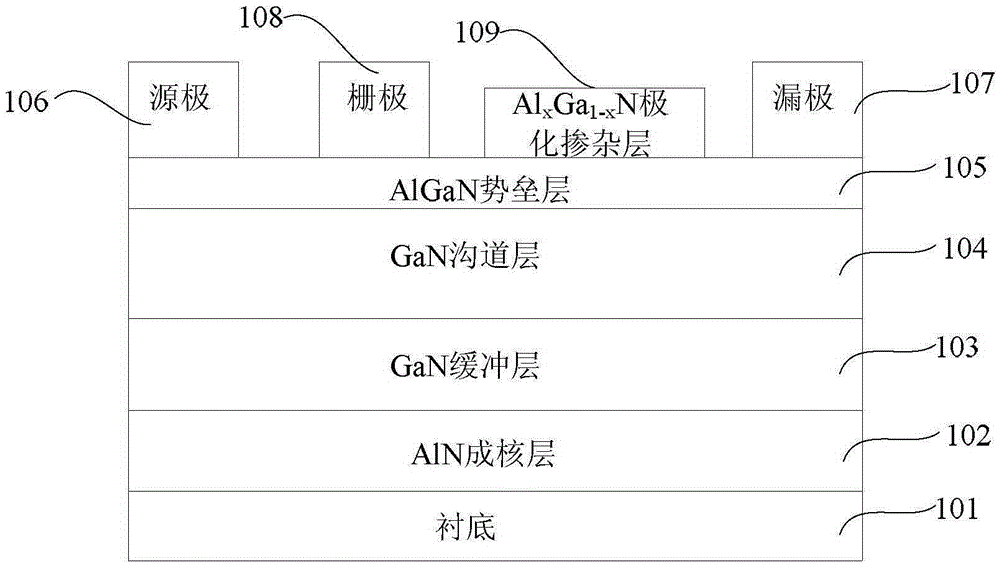

[0027] Such as figure 2 As shown, the GaN-based high electron mobility transistor with high breakdown voltage in this embodiment mainly consists of substrate 101, AlN nucleation layer 102, GaN buffer layer 103, GaN channel layer 104, AlGaN barrier layer 105, and the source 106, drain 107 and gate 108 formed on the AlGaN barrier layer 105, as an improvement, the GaN-based high electron mobility transistor also includes an AlGaN barrier layer 105 and between the gate 108 and the drain 107 is formed with an Al composition gradient Al x Ga 1-x N-polarized doped layer 109 .

[0028] Al in this example x Ga 1-x The thickness of the N-polarized doped layer 109 is between 50nm and 500nm, and the Al x Ga 1-x The Al composition on the upper surface of the N-polarized doped layer 109 is 0, and the Al composition on the lower surface is the same as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com