Graphene aerogel material and preparation method thereof

A technology of graphene airgel and graphene hydrogel, which is applied in the field of composite materials, can solve the problem of high thermal conductivity, achieve the effect of improving high thermal conductivity and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] As mentioned above, the present invention provides a method for preparing a graphene airgel material in a first aspect. Generally speaking, described method of the present invention mainly comprises the following steps: preparation precursor solution, sol-gel reaction, solvent replacement and drying (for example figure 1 shown).

[0017] More specifically, the method of the present invention may include the following steps:

[0018] (1) Preparing the precursor solution: mixing the graphene oxide and the skeleton filler and stirring evenly to obtain the precursor solution;

[0019] (2) Preparation of graphene hydrogel: add catalyst to the precursor solution and stir evenly, then pour into a mold with reinforcing fibers and seal, heat the mold to react, and obtain fiber-reinforced graphene hydrogel;

[0020] (3) preparing graphene ketone gel: placing the graphene hydrogel in an acetone solution for solvent replacement to obtain graphene ketone gel;

[0021] (4) Prepara...

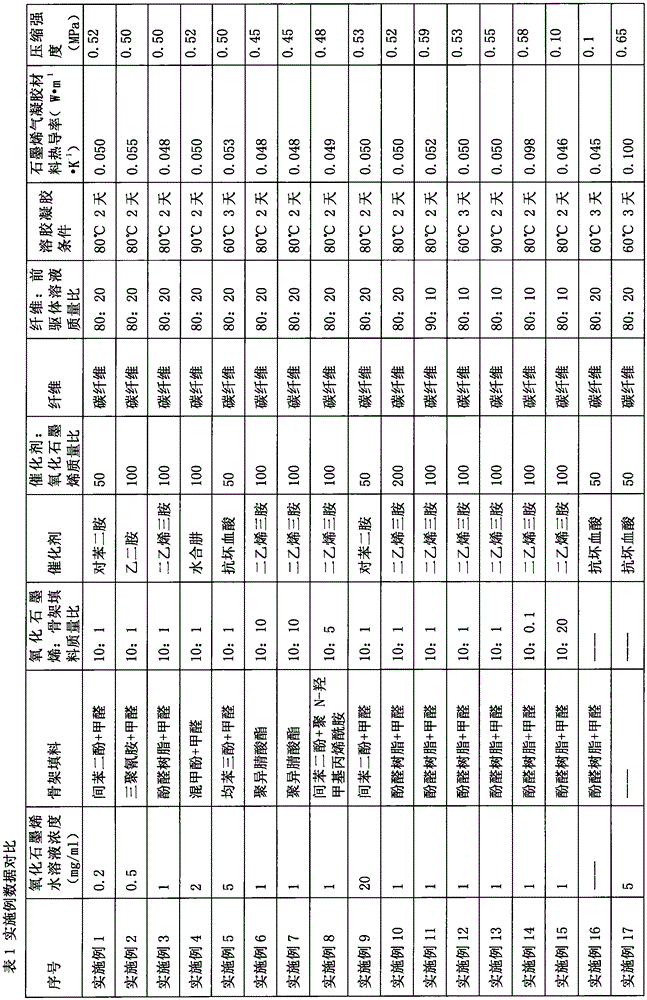

Embodiment 1

[0032] Adopt 0.2mg / ml graphene oxide solution, resorcinol+formaldehyde system as the skeleton filler, the mass ratio of graphene oxide and skeleton filler is 10:1, after the two are mixed evenly, add 50 times of graphene oxide quality p-Phenylenediamine, after stirring evenly, pour it into the mold where the carbon fiber was placed in advance, the mass ratio of the carbon fiber to the precursor solution is 80:20, after sealing, put it in an oven, react at 80 °C for 2 days, and obtain graphite Alkene hydrogel. The graphene hydrogel after the sol-gel was taken out, placed in an acetone solution, and the solvent was replaced, and the acetone was replaced once every 2 days, and the acetone was replaced 3 times in total to obtain the graphene ketone gel of the acetone solvent. The graphene ketone gel is taken out and subjected to supercritical drying to prepare a fiber-reinforced graphene airgel material. The thermal conductivity and material strength (compressive strength, the sa...

Embodiment 2

[0036]Use 0.5 mg / ml graphene oxide solution, melamine + formaldehyde system as the skeleton filler, the mass ratio of graphene oxide and skeleton filler is 10:1, after the two are mixed evenly, add ethylenediamine 100 times the mass of graphene oxide After stirring evenly, pour it into the mold where the carbon fiber was placed in advance. The mass ratio of the carbon fiber to the precursor solution is 80:20. After sealing, put it in an oven and react for 2 days at 80 ° C to obtain a graphene hydrogel. . The graphene hydrogel after the sol-gel was taken out, placed in an acetone solution, and the solvent was replaced, and the acetone was replaced once every 2 days, and the acetone was replaced 3 times in total to obtain the graphene ketone gel of the acetone solvent. The graphene ketone gel is taken out and subjected to supercritical drying to prepare a fiber-reinforced graphene airgel material. The thermal conductivity and material strength of the resulting material were the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com