A kind of method adopting plasma method to prepare nano metal silicon

A nano-metal silicon and plasma technology, applied in the direction of silicon, etc., can solve the problems that cannot meet the requirements of aerospace, metal silicon nano-particle crystal defects, and short service life of electronic components, and achieve low production cost and no crystal lattice. Effect of defects, narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

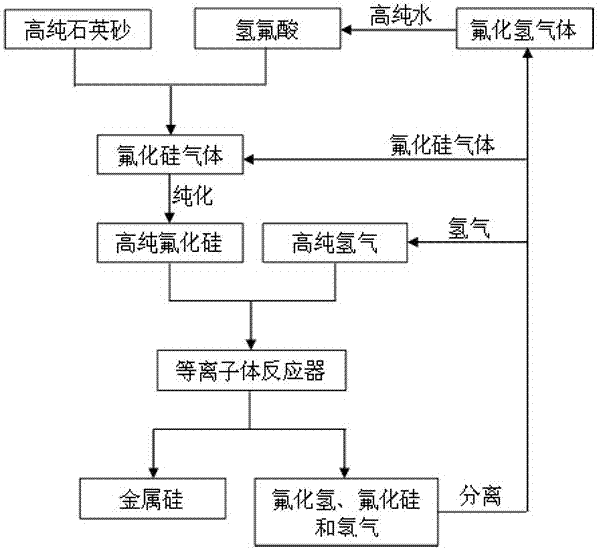

[0027] The present embodiment provides a kind of method adopting plasma method to prepare nano-metal silicon, it comprises the following steps:

[0028] A. 10g of quartz sand and 150mL of hydrofluoric acid with a mass content of 10% to 50% are reacted to generate silicon fluoride gas;

[0029] B. Purifying and removing impurities from the silicon fluoride gas prepared in step A to obtain high-purity silicon fluoride gas (mass content ≥ 98.5%);

[0030] C. Completely mix the high-purity silicon fluoride gas obtained in step B with hydrogen in a metered volume ratio of 1:4; then pass the mixed gas into the plasma reactor at a flow rate of 50mL / min for reaction to generate metal Silicon nanoparticles (particle size ≤ 50nm) and hydrogen fluoride gas;

[0031] D. Separating and purifying the mixture of unreacted silicon fluoride, hydrogen and generated hydrogen fluoride gas through a separator to obtain qualified high-purity silicon fluoride (mass content ≥ 98.5%) and hydrogen (ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com