Preparation and application of iron-nitrogen co-doped porous carbon material

A porous carbon material, co-doping technology, used in special compound water treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of easy agglomeration, high surface energy, and low utilization of active sites problems, to achieve the effect of improving utilization, prolonging service life, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

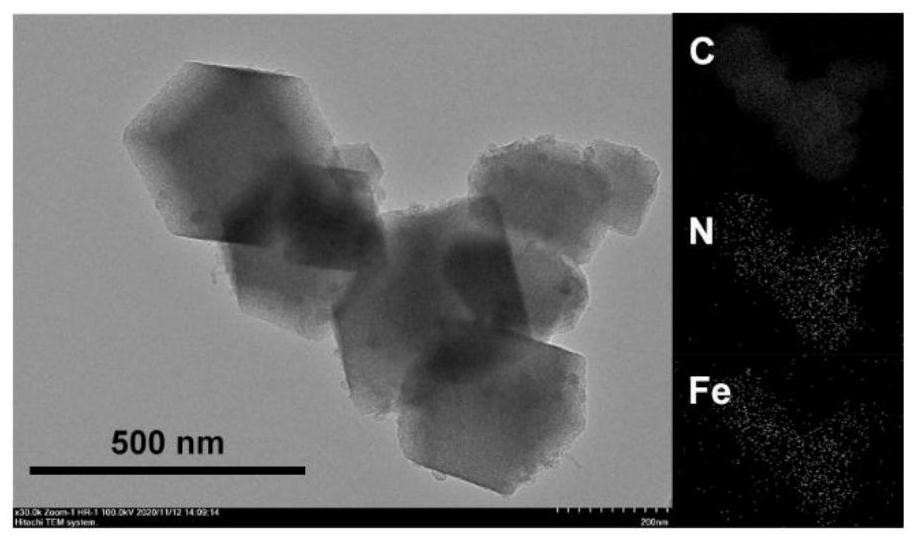

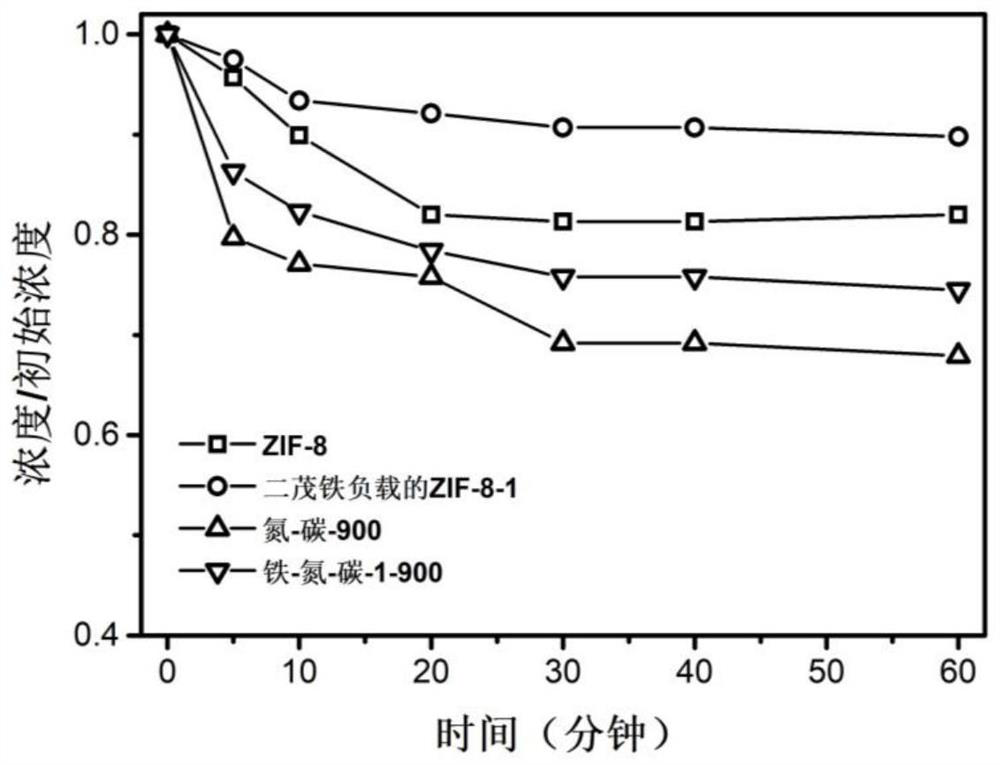

Embodiment 1

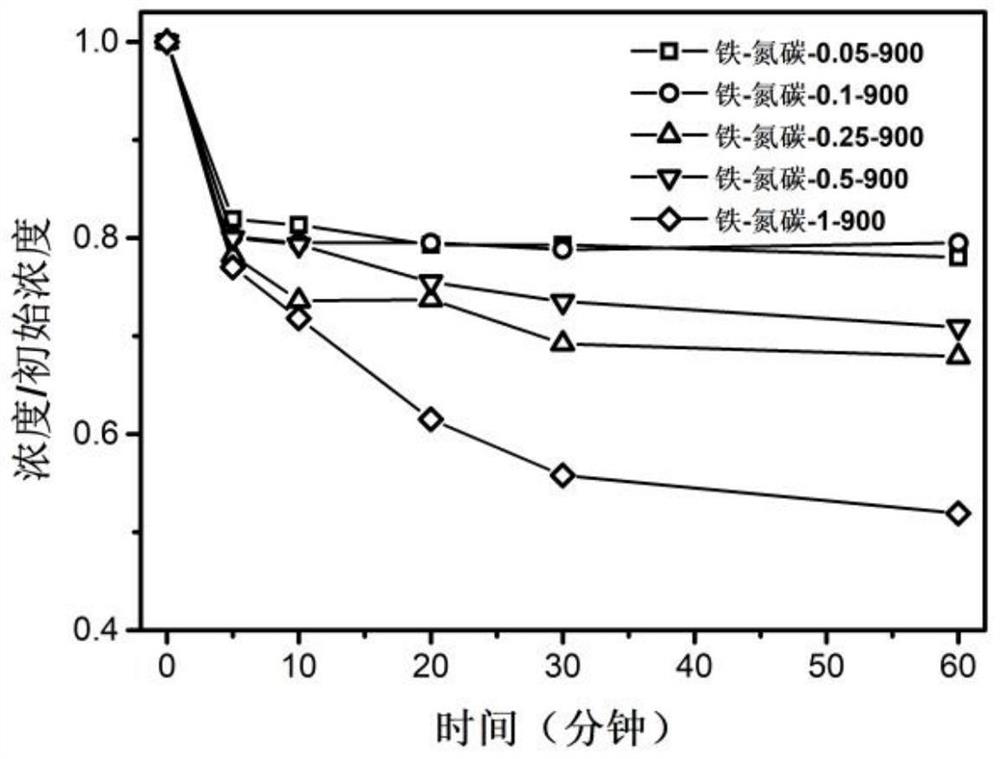

[0052]Weighed 74.4 mg of ferrocene and 2380.0 mg of zinc nitrate hexahydrate and dissolved them in 60 mL of anhydrous methanol to obtain a clear solution A. Simultaneously, 2628.0 mg of 2-methylimidazole was dissolved in 30 mL of absolute methanol to obtain a clear solution B. A and B were mixed and reacted for 10 h at room temperature with stirring. After the reaction, the obtained dispersion was centrifuged at 3000rpm / min for 30min, and the light yellow precipitate was collected, washed three times with anhydrous methanol and anhydrous ethanol solutions, and then vacuum-dried at 40°C for 24h to obtain a ferrocene-loaded ZIF- 8 metal organic framework powder. Weigh 500mg ferrocene-loaded ZIF-8 metal-organic framework powder into a covered quartz boat, pass through Ar, heat from room temperature to 900°C at a rate of 2.5°C / min and hold for 24h. After cooling, the obtained black powder was washed with 0.5 mol / L dilute sulfuric acid for 8 hours, and then vacuum-dried to obtain...

Embodiment 2

[0055] The difference between this embodiment and embodiment 1 is that the input amount of ferrocene is 148.8 mg.

Embodiment 3

[0057] The difference between this embodiment and embodiment 1 is that the input amount of ferrocene is 372.0 mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com