Method for preparing monodispersed superparamagnetic iron oxide nanoparticles by pyrolysis of ferrocene

A superparamagnetic iron oxide and nanoparticle technology, applied in iron oxide/iron hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of no iron oxide magnetic nanoparticle research, high requirements for the reaction system, etc., and achieve good magnetic properties Ability, the effect that the size is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

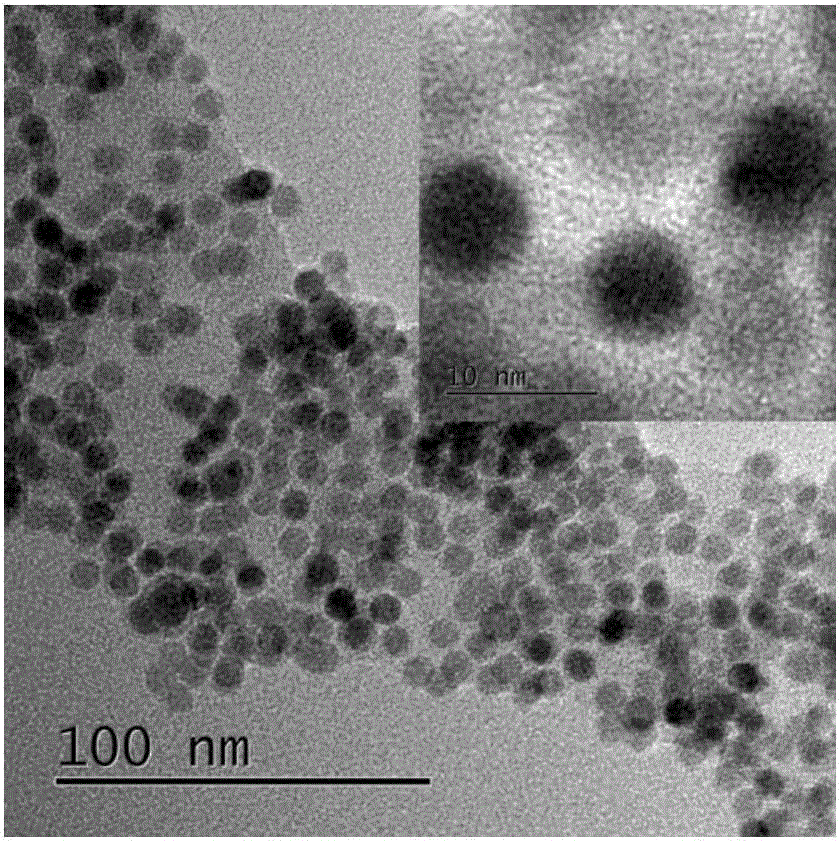

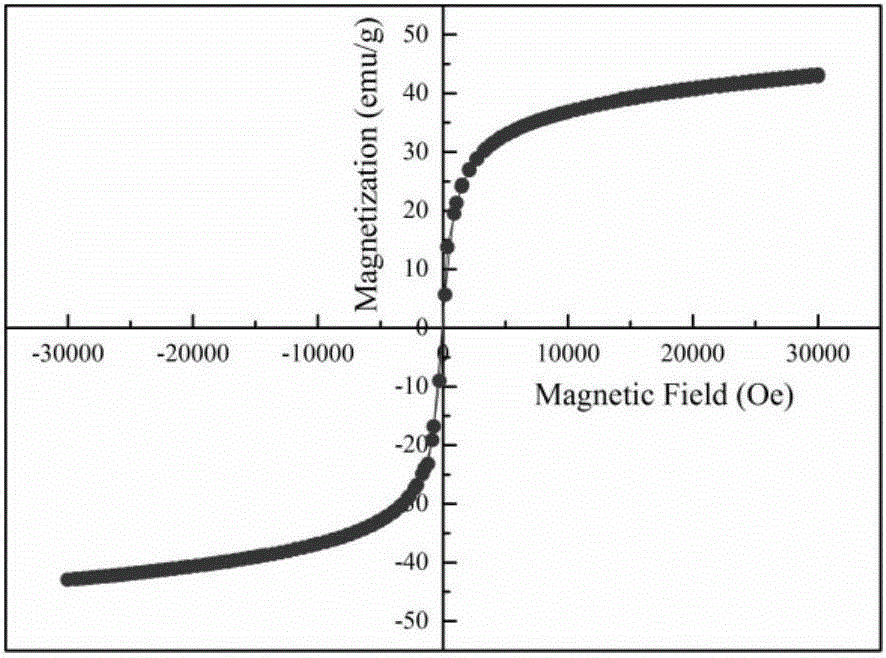

[0021] Example 1: Preparation of superparamagnetic monodisperse nanoparticles by thermal decomposition of ferrocene

[0022] Disperse 0.74g of ferrocene in 20g of octadecene, then add 0.57g of oleic acid, pour it into a three-necked flask with a thermometer and a condenser after dispersing, raise the temperature to 95°C, keep it for 10min, and then increase the temperature at 3.3°C / min The heating rate was raised to 320°C and kept for 3h. When the temperature was lowered to room temperature after the reaction, the product was poured out, and the product was washed 5 times with a mixed solvent of n-hexane and ethanol with a volume ratio of 1:3 to obtain monodisperse superparamagnetic nanoparticles, and finally the product was dispersed in chloroform for storage.

Embodiment 2

[0023] Example 2: Preparation of superparamagnetic monodisperse nanoparticles by thermal decomposition of ferrocene

[0024] Disperse 1.48g of ferrocene in 20g of eicosene, then add 0.57g of oleic acid, pour it into a three-necked flask with a thermometer and a condenser after dispersing, raise the temperature to 90°C, keep it for 20min, and then increase the temperature at 3.3°C / min The heating rate was increased to 330°C and kept for 5h. When the temperature was lowered to room temperature after the reaction, the product was poured out, and the product was washed 5 times with a mixed solvent of n-hexane and ethanol with a volume ratio of 1:3 to obtain monodisperse superparamagnetic nanoparticles, and finally the product was dispersed in chloroform for storage.

Embodiment 3

[0025] Example 3: Preparation of superparamagnetic monodisperse nanoparticles by thermal decomposition of ferrocene

[0026] Disperse 1.48g of ferrocene in 40g of octadecene, then add 6.84g of oleic acid, pour it into a three-necked flask with a thermometer and a condenser after dispersing, raise the temperature to 90°C, keep it for 20min, and then increase the temperature at 3.3°C / min The heating rate was raised to 320°C and kept for 1h. When the reaction is completed and the temperature is lowered to room temperature, the product is poured out, and the product is washed 5 times with a mixed solvent with a volume ratio of n-hexane and ethanol of 1:3 to obtain monodisperse superparamagnetic nanoparticles, and finally the product is dispersed in dichloromethane for preservation .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com