Composite friction material and its preparation method and preparation device

A technology of composite friction materials and compounds, which is applied in the field of material science, can solve the problems of composite material products such as limited use, high wear rate, wear resistance, and poor self-lubrication, and achieve light weight, uniform distribution, and wide operating temperature range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

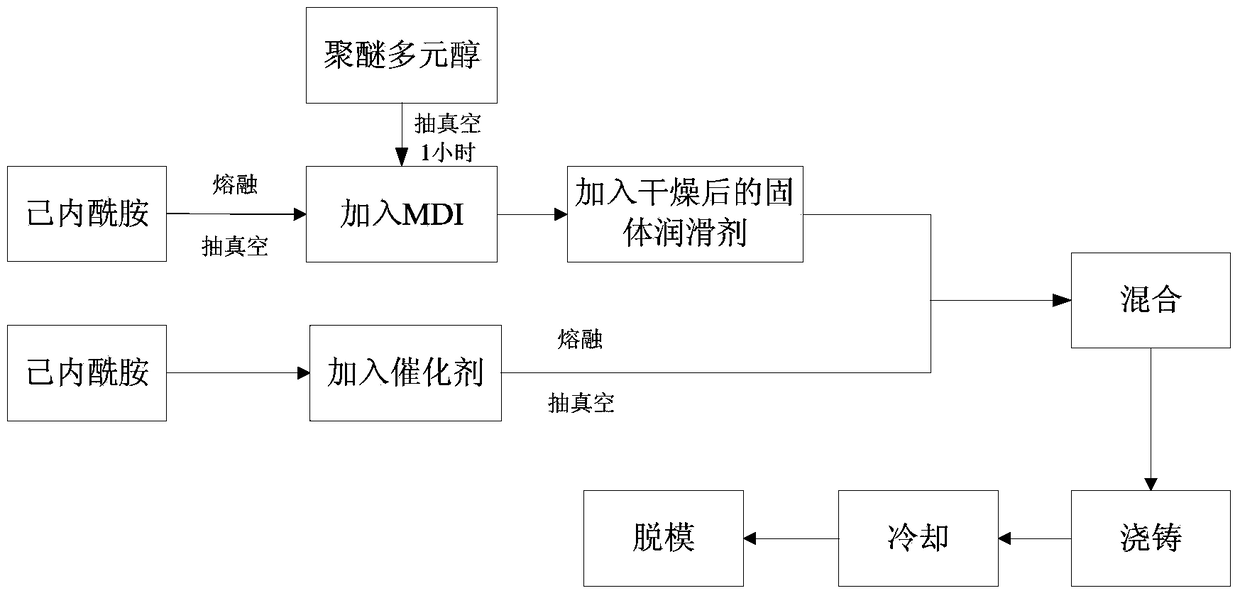

[0049] A preparation method of the composite friction material of the present invention, the process flow is as follows figure 1 shown, including the following steps:

[0050] (1) Add 410g caprolactam monomer and 8.2g catalyst sodium hydroxide into the first reaction kettle 1 and heat to 130°C, melt, vacuumize (vacuum degree-0.1MPa), and dehydrate for 20min to obtain the first reaction liquid (caprolactam anion ).

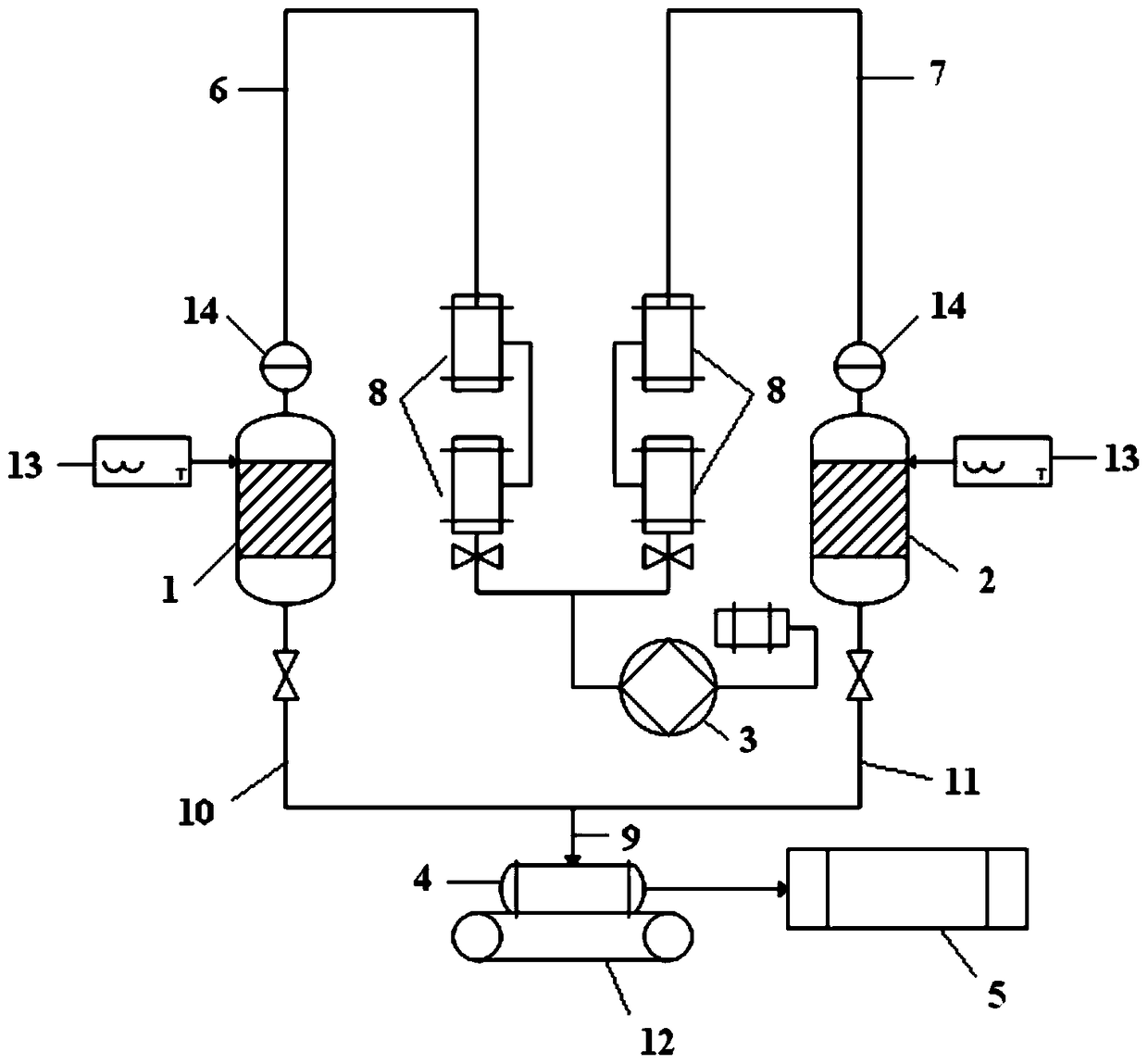

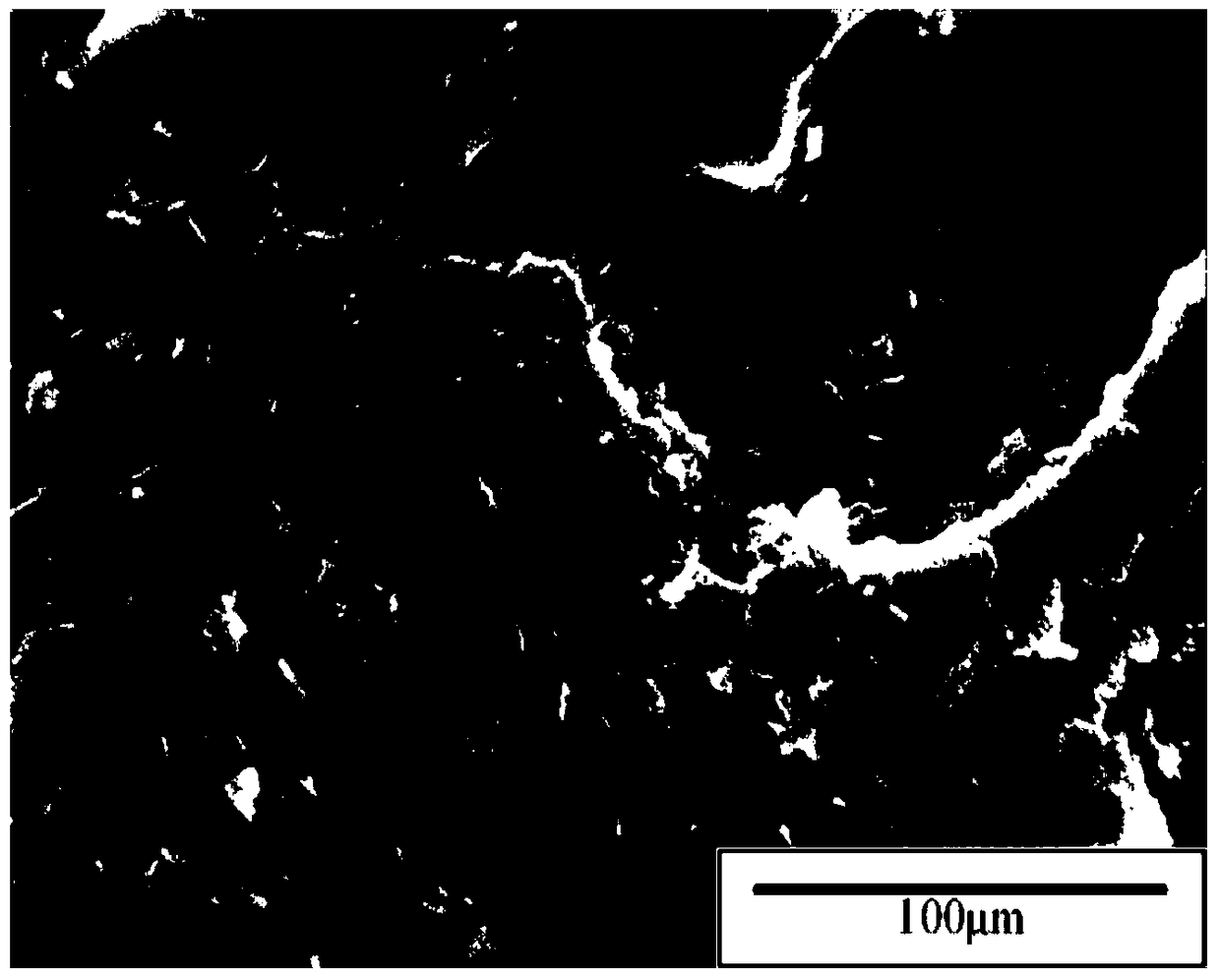

[0051] (2) Add 400g of caprolactam monomer into the second reaction kettle 2, melt at 130°C, vacuum dehydrate for 10min, and the vacuum degree is -0.1MPa, mix 72g of polyether glycol (which has been vacuumized for 1 hour) and 18g of di Benzyl methane diisocyanate MDI is added in the second reactor 2, reacts 0.5h, finally adds the colloidal graphite lubricant (the molybdenum disulphide that also has -OH group on the surface for use with -OH group after drying) lubricant, polytetrafluoroethylene lubricant) 45g, and then reacted for 0.5h to obtain the second reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com