Lysobacter capable of efficiently degrading aflatoxin B1 and ochratoxin A and application of Lysobacter

A technology of aflatoxin and ochratoxin, applied in the field of microbiology and biodegradation, can solve the problems of rare reports and no substantial detoxification significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

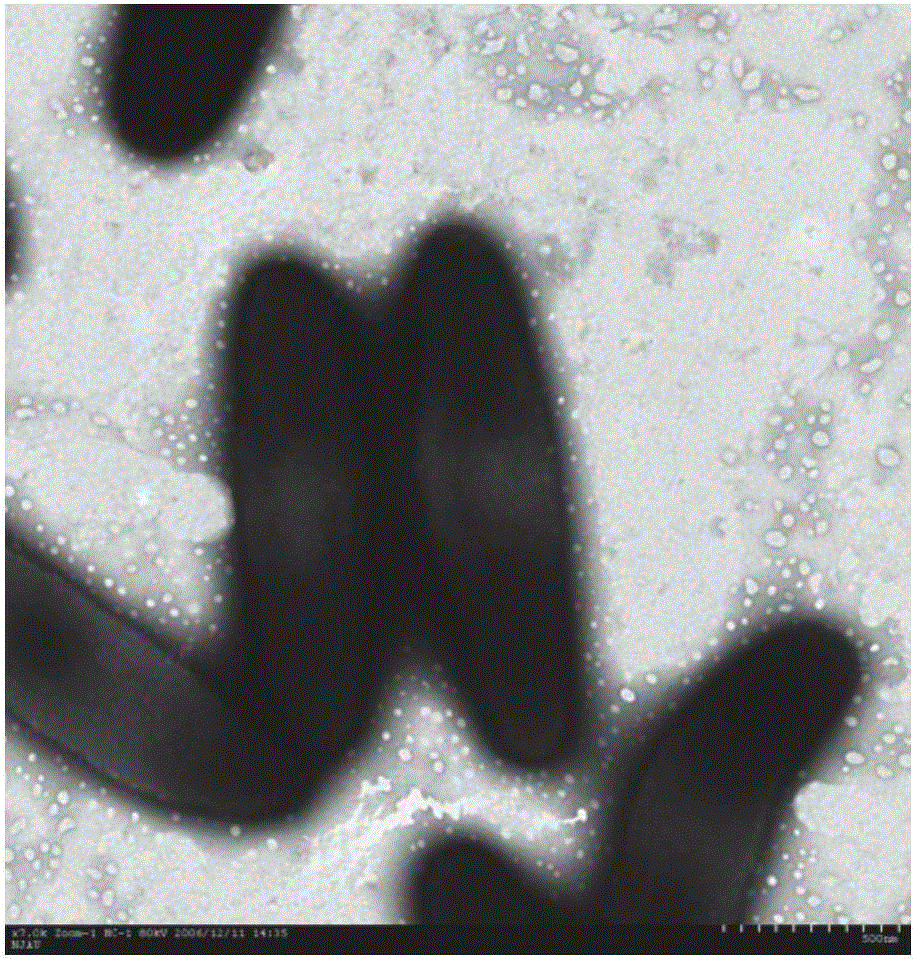

[0022] Example 1 Screening, identification and cultivation of aflatoxin B1 and ochratoxin A degrading bacteria

[0023] 1. Screening of bacterial strains

[0024] The samples were collected from soil heavily polluted by PAHs (near oil refineries, auto repair shops) and moldy food heavily polluted by mycotoxins. Take 0.5 g of the collected sample and add it to 150 mL of enrichment medium (the contents of OTA and AFB1 are about 20 μg / L each), and enrich and culture in a constant temperature incubator at 30°C for 7 days. After the first enrichment culture, inoculate 5 mL of the enrichment culture solution into 150 mL of fresh OTA and AFB1 enrichment medium, increase the concentration of OTA and AFB1 to 30 μg / L, and continue the enrichment culture under the same conditions for 7 sky. Complete the third enrichment culture experiment with the same enrichment method, increasing the concentration of OTA and AFB1 to 50μg / L. After the enrichment culture was completed, the enriched cu...

Embodiment 2

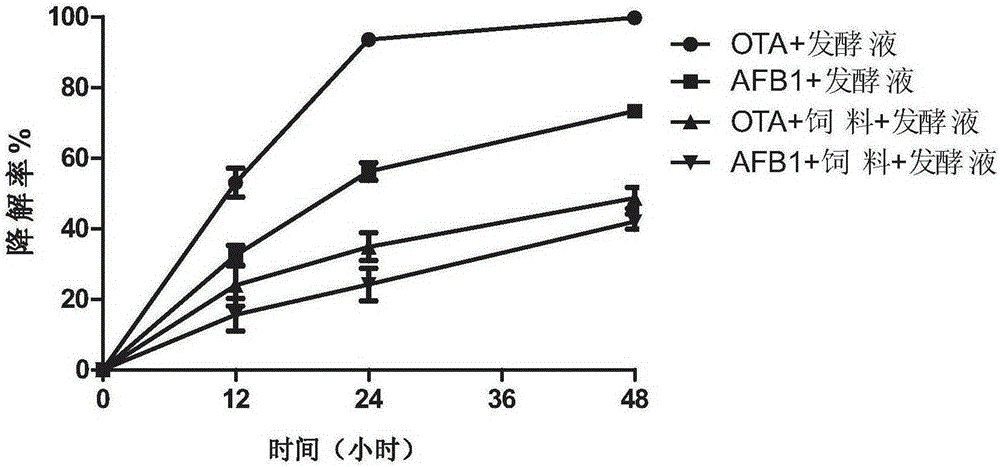

[0034] Example 2 Degradation characteristics of bacterial strain CW239 detected by high performance liquid chromatography

[0035] Degradation dynamic detection of degrading strains: The degrading strain CW239 was continuously activated for 2 generations on the most suitable solid medium, inoculated in 4mL liquid medium for overnight culture, and fresh bacterial liquid was obtained. Inoculate 50 μL of fresh bacteria liquid into 4mL LOTA test medium (containing 20.0 μg / LOTA) and AFB1 test medium (containing 20.0 μg / LAFB1) respectively, shake the inoculated test tube for 0h, 12h, 24h and 48h, and degrade each The experiment was set up with 3 repetitions. Escherichia coli K12 (E.coliK12) was used as a negative control strain. After the culture was completed, mix well, centrifuge at 8000r / min for 10min, and collect the supernatant and bacterial precipitate respectively.

[0036] The degraded supernatant was passed through the OTA immunoaffinity column and the AFB1 immunoaffinity...

Embodiment 3

[0041] Example 3 Application of bacterial strain CW239 in detoxification treatment of corn soybean meal type feed

[0042] 1. Experimental materials

[0043] Strain activation medium Ⅰ: tryptone 17.0g / L, soytone 3.0g / L, glucose 2.5g / L, NaCl 5.0g / L, K 2 HPO 4 2.5g / L, agar 20.0g / L.

[0044] Strain activation medium II: peptone 5.0g / L, beef extract 30.0g / L, NaCl 5.0g / L, pH7.0-7.2.

[0045] The above-mentioned medium was autoclaved at 120°C for 15 minutes, and the experimental feed was a corn-soybean meal-based diet.

[0046] 2. Experimental method

[0047] Add an appropriate amount of OTA and AFB1 standard stock solution to 50mL of phosphate buffer solution, mix it and immediately pour it into 100g of the crushed feed sample, stir evenly, so that the final concentration of OTA and AFB1 reaches 40.0μg / kg respectively, and feed in Dry in a cool and ventilated place for later use. Continuously activate the strains to be tested for 2 generations on the solid activation medium I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com