Hot-rolling strip-steel harrow disk suitable for water quenching and manufacture method thereof

A technology for hot-rolled strip steel and a manufacturing method, which is applied in the field of metallurgy and can solve the problems of unmentioned steel plate properties, low carbon content, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is described in detail below by specific embodiments of the present invention

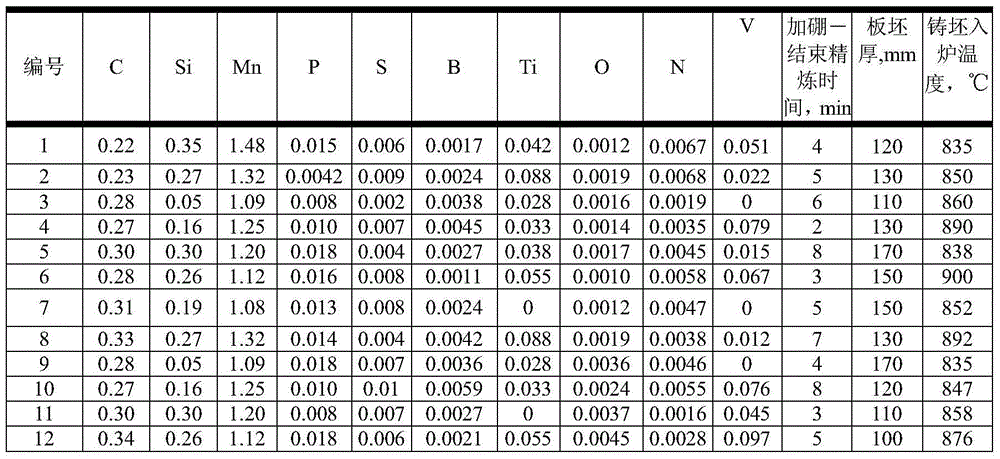

[0054] The present invention is a hot-rolled strip steel rake suitable for water quenching, the chemical composition of which is calculated by weight percentage: C: 0.22%-0.34%, Si: 0.1%-0.40%, Mn: 1.0%-1.5%, N≤ 0.0070%, Ti: ≤0.1%, B: 0.001%~0.006%, V: ≤0.1%, impurity elements P≤0.020% and S≤0.010%, the balance is Fe and unavoidable impurities.

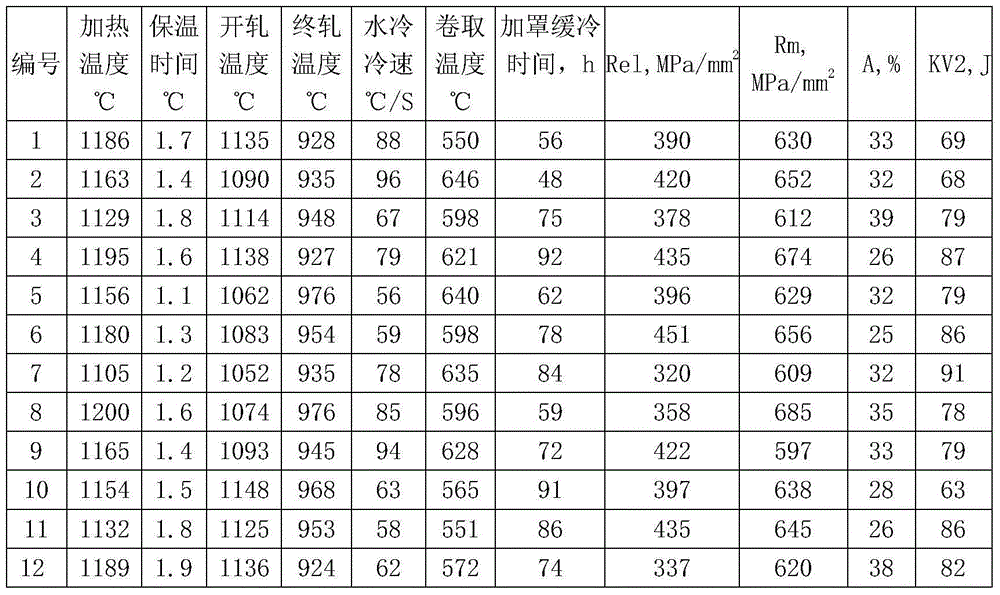

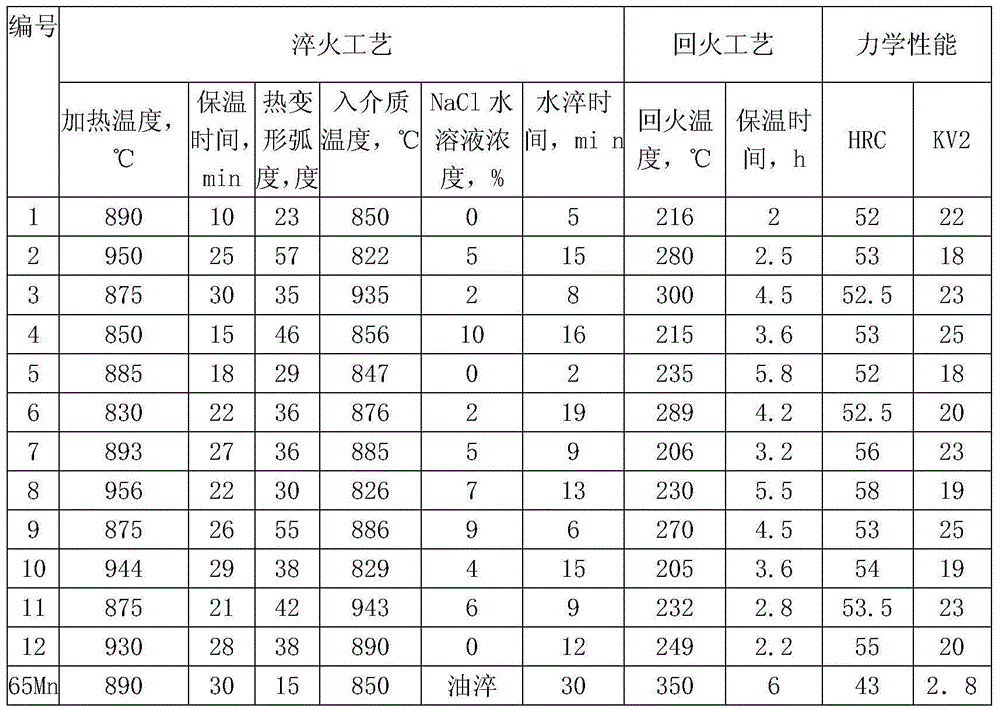

[0055] The steel with the above composition is used to manufacture hot-rolled strip steel rakes suitable for water quenching. The process includes converter smelting, electric furnace refining, slab continuous casting and rolling, ultra-rapid cooling, slow cooling after coiling, stamping, quenching, and tempering. , the specific process is as follows:

[0056] 1), strip steel smelting process:

[0057] (1) During the smelting process, it is required to add a deoxidizer to deoxidize after refining to ensure that O≤0.002%, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com