Spinning and drawing oil solution used for polypropylene fibers

A technology of polypropylene fiber and drawing oil, which is applied in the direction of fiber type, fiber treatment, textiles and papermaking, etc. It can solve the problems of corrosion and adverse effects of fiber dyeing, and achieve uniform adhesion, good spinnability and stable application performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

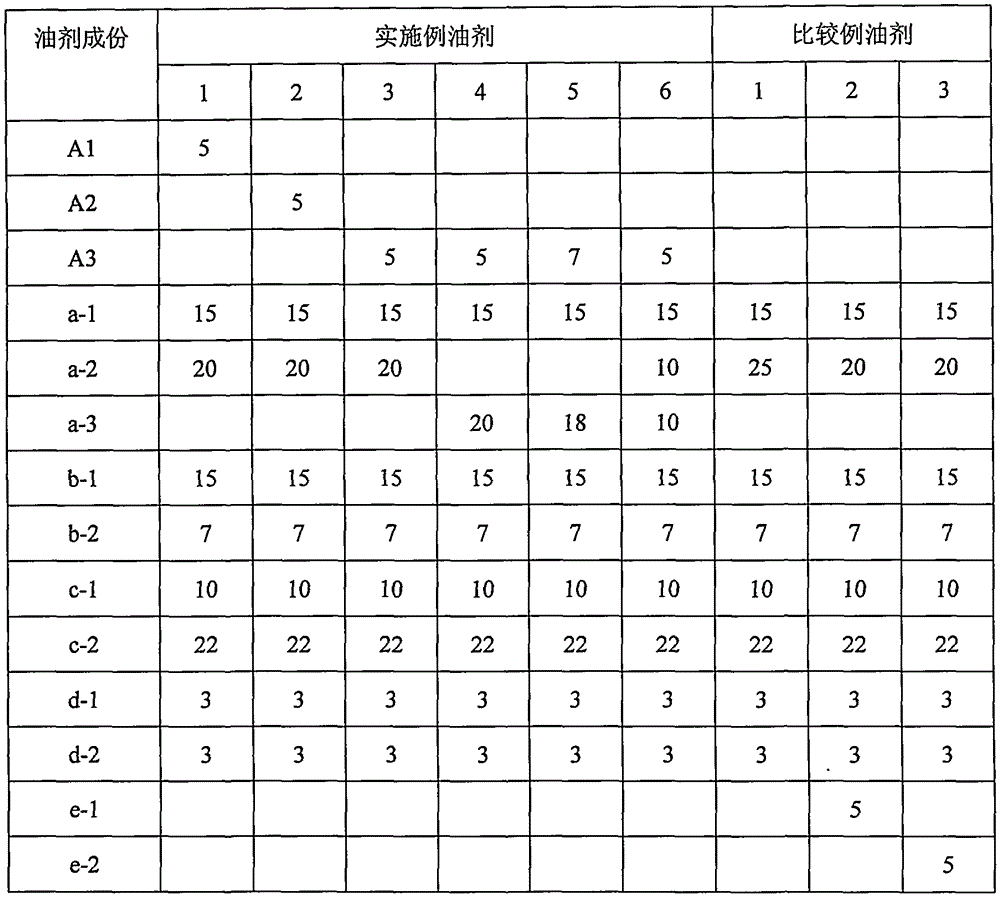

Embodiment 1~6】 and 【 comparative example 1~3

[0043] 1. Oil preparation:

[0044] Embodiment 1~6 and comparative example 1~3, allocate the oil agent of the present invention (embodiment 1~6) and comparative example (comparative example 1~3) with the component of table 1 record and parts by weight, oil agent composition in table 1 The substances represented by a column of symbols are as follows:

[0045] a-1 mineral oil

[0046] a-2 Octyl stearate

[0047] a-3 Dioctyl sebacate

[0048] b-1 castor oil polyoxyethylene ether (30)

[0049] b-2 Lauryl alcohol polyoxyethylene ether (7)

[0050] c-1 nonylphenol polyoxyethylene ether (10)

[0051] c-2 polyoxyethylene laurate (9)

[0052] d-1 dodecyl phosphate potassium salt

[0053] d-2 Lauryl polyoxyethylene ether (3) phosphate potassium salt

[0054] e-1 isotridecanyl polyoxyethylene ether (7)

[0055] e-2 lauryl polyoxyethylene ether (5).

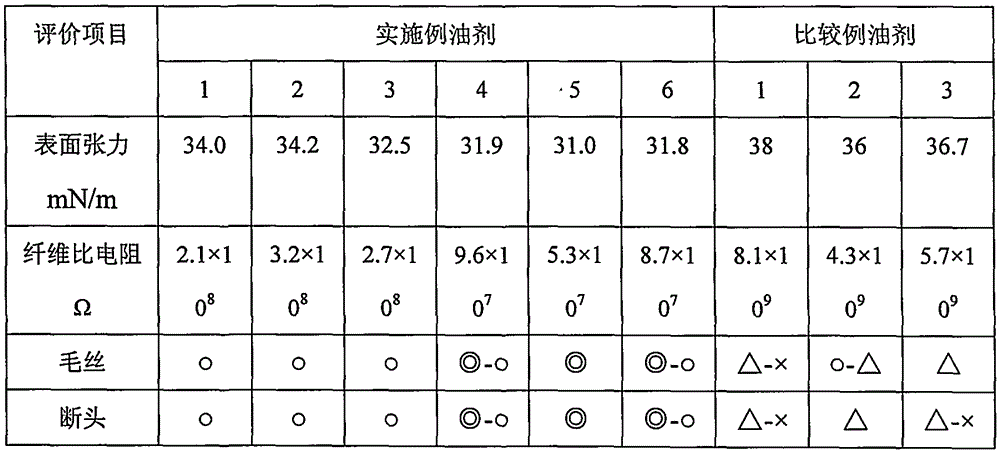

[0056] 2. Oil agent performance test

[0057] Prepare each embodiment oil agent and comparative example oil agent with the oil age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com