Preparation method of polysulfone modification based anionic membrane having ultralow aqueous solution swelling degree for fuel cell

An anion membrane and fuel cell technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of conductivity loss, alkali resistance reduction, unfavorable environmental protection, etc., to improve ion exchange capacity and conductivity, and good mechanical properties , Excellent alkali resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

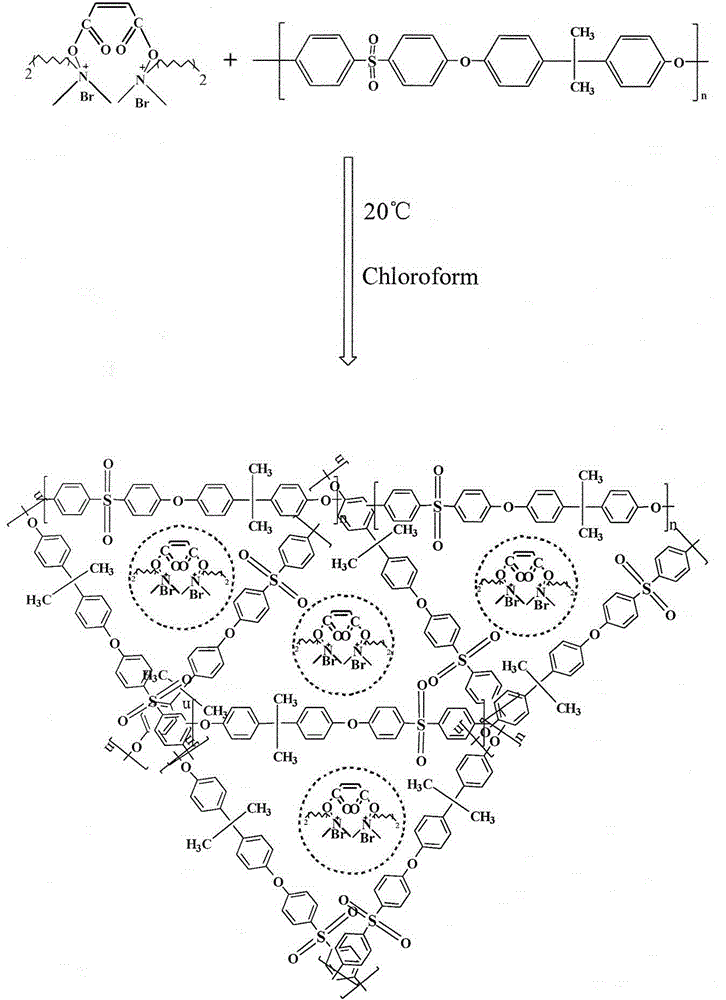

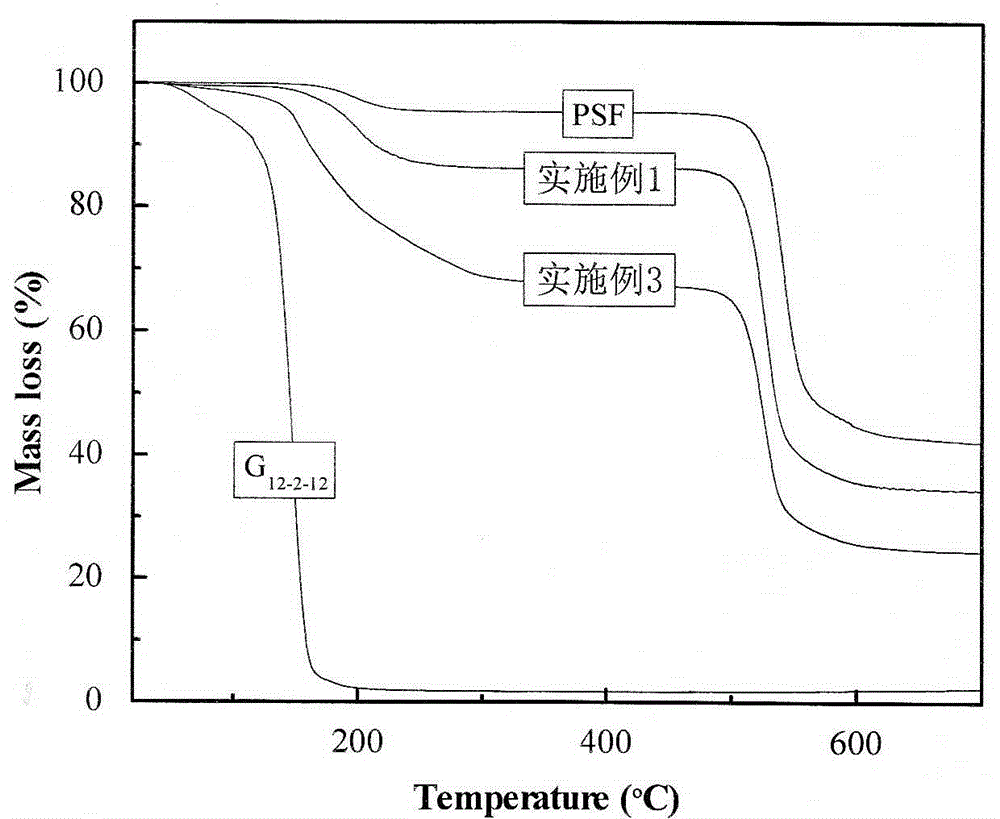

[0019] Doping G 12-2-12 The preparation method of cationic polysulfone modified anionic membrane comprises the following steps:

[0020] Step 1. Weigh 5g of polysulfone particles, add them to a beaker containing 20mL of chloroform solvent, and perform magnetic stirring at room temperature. After the polysulfone is completely dissolved, add G with a purity of 50%. 12-2-12 type molecule 1.11g, making G in the prepared anion membrane 12-2-12 The mass percentage of type molecule is 10%, continue to stir at room temperature until it is completely dissolved, ultrasonically oscillate for 30 minutes, and centrifuge to defoam. Then cast a film on a horizontal glass plate by casting method, and peel it off after the film is naturally air-dried.

[0021] Step 2, immerse the film in 100mL deionized water, change the water every 20min, after soaking for 3 hours, dry the deionized water on the surface of the composite film, place it at room temperature (48h), slowly evaporate the water in...

Embodiment 2

[0024] Doping G 12-2-12 The preparation method of cationic polysulfone modified anionic membrane comprises the following steps:

[0025] Step 1. Weigh 5g of polysulfone particles, add them to a beaker containing 20mL of chloroform solvent, and perform magnetic stirring at room temperature. After the polysulfone is completely dissolved, add G with a purity of 50%. 12-2-12 Type molecule 2.5g, so that G in the prepared anion membrane 12-2-12 The mass percentage of the type molecule is 20%, continue to stir at room temperature until it is completely dissolved, ultrasonically oscillate for 30 minutes, and centrifuge to defoam. Then cast a film on a horizontal glass plate by casting method, and peel it off after the film is naturally air-dried.

[0026] Step 2, immerse the film in 100mL deionized water, change the water every 20min, after soaking for 3 hours, dry the deionized water on the surface of the composite film, place it at room temperature (48h), slowly evaporate the wate...

Embodiment 3

[0029] Doping G 12-2-12 The preparation method of cationic polysulfone modified anionic membrane comprises the following steps:

[0030] Step 1. Weigh 5g of polysulfone particles, add them to a beaker containing 20mL of chloroform solvent, and perform magnetic stirring at room temperature. After the polysulfone is completely dissolved, add G with a purity of 50%. 12-2-12 type molecule 4.30g, so that G in the prepared anion membrane 12-2-12 The mass percentage of type molecules is 30%, continue to stir at room temperature until completely dissolved, ultrasonically oscillate for 30 minutes, and centrifuge to defoam. Then cast a film on a horizontal glass plate by casting method, and peel it off after the film is naturally air-dried.

[0031] Step 2, immerse the film in 100mL deionized water, change the water every 20min, after soaking for 3 hours, dry the deionized water on the surface of the composite film, place it at room temperature (48h), slowly evaporate the water in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com