Preparation technology for improving purity of doxycycline hyclate injection

A technique for preparing doxycycline hydrochloride and its preparation technology, which is applied in the field of preparation technology for improving the purity of doxycycline hydrochloride injection, and can solve the problems of slow dissolution rate and doxycycline hydrochloride containing impurities, so as to improve the purity and overcome the dissolution problem. Slower speed, avoiding the effect of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

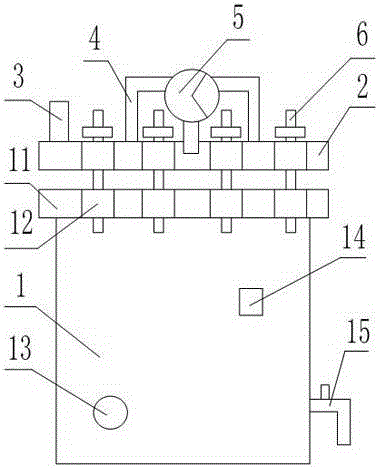

[0025] Such as figure 1 Shown, based on improving the preparation technology of doxycycline hydrochloride injection purity, comprises the following steps:

[0026] 1) Preparation of doxycycline hydrochloride: Grind 5 g of doxycycline hydrochloride into powder with a ball mill, then dissolve the powder in water to form solution A; the percentage of doxycycline in the doxycycline hydrochloride The content is 15%; Dissolve 10g of ethyl cellulose in ethanol to form solution B; under the premise of stirring, gradually pour solution A into solution B, and solution A will form emulsion C after solution B is dispersed; gelatin Dissolve in distilled water in a 60°C water bath to make a protection solution D, keep the temperature at 30°C for use; add emulsion C dropwise to the protection solution D under stirring to form a solution E, raise the water bath from 30°C to 50°C, and stir The organic solvent is volatilized; then E is suction-filtered and washed with water to obtain a doxycyc...

Embodiment 2

[0030] Such as figure 1 Shown, based on improving the preparation technology of doxycycline hydrochloride injection purity, comprises the following steps:

[0031] 1) Preparation of doxycycline hydrochloride: Grind 5 g of doxycycline hydrochloride into powder with a ball mill, then dissolve the powder in water to form solution A; the percentage of doxycycline in the doxycycline hydrochloride The content is 20%; Dissolve 15g of ethyl cellulose in ethylene glycol to form solution B; under the premise of stirring, gradually pour solution A into solution B, and solution A forms emulsion C after solution B is dispersed; Dissolve gelatin and distilled water in an 80°C water bath to make protection solution D, keep the temperature at 30°C for use; add emulsion C dropwise to protection solution D under stirring to form solution E, and raise the water bath from 30°C to 50°C , stirred to volatilize the organic solvent, then E was suction filtered and washed to obtain a doxycycline hydr...

Embodiment 3

[0035] Such as figure 1 Shown, based on improving the preparation technology of doxycycline hydrochloride injection purity, comprises the following steps:

[0036]1) Preparation of doxycycline hydrochloride: Grind 6 g of doxycycline hydrochloride into powder with a ball mill, then dissolve the powder in water to form solution A; the percentage of doxycycline in the doxycycline hydrochloride The content is 25%; Dissolve 12g of ethyl cellulose in dichloromethane to configure solution B; under the premise of stirring, gradually pour solution A into solution B, and solution A forms emulsion C after solution B is dispersed; Dissolve gelatin and distilled water in a 70°C water bath to make protection solution D, keep the temperature at 30°C for use; add emulsion C dropwise to protection solution D under stirring to form solution E, and raise the water bath from 30°C to 50°C , stirring to volatilize the organic solvent; then E is suction filtered and washed to obtain a doxycycline h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com