Method for rapidly preparing methanation catalyst by microwave calcination

A methanation catalyst and microwave calcination technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of difficult adjustment of catalyst performance and cumbersome catalyst preparation process , poor anti-carbon deposition effect and other problems, to achieve good anti-carbon performance, avoid heat accumulation, and avoid the loss of active components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

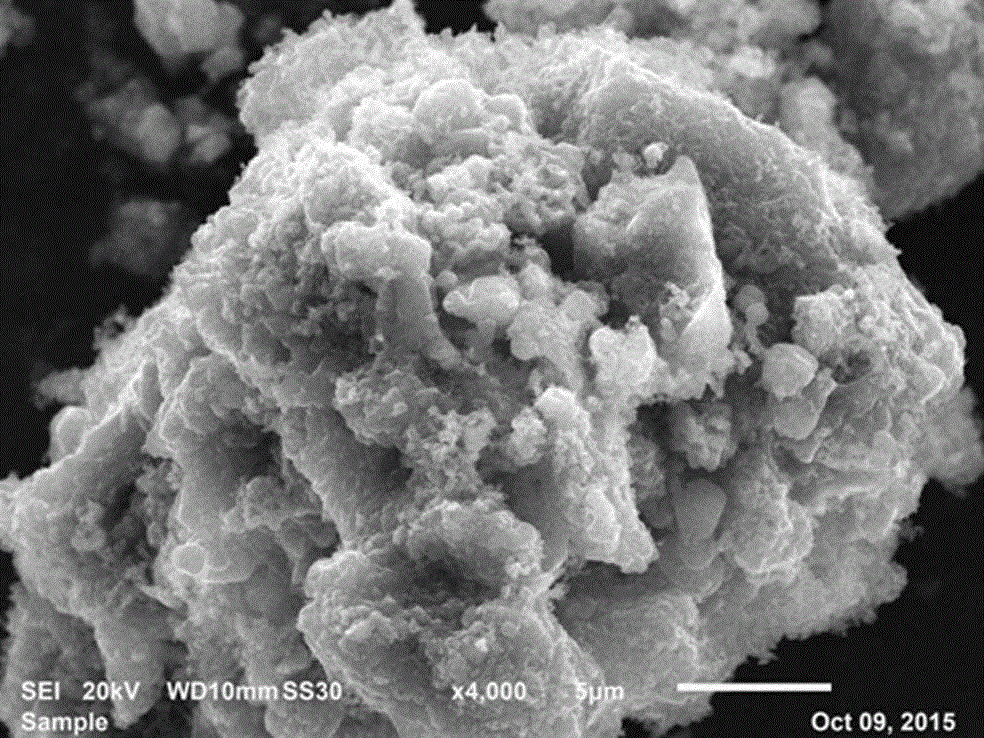

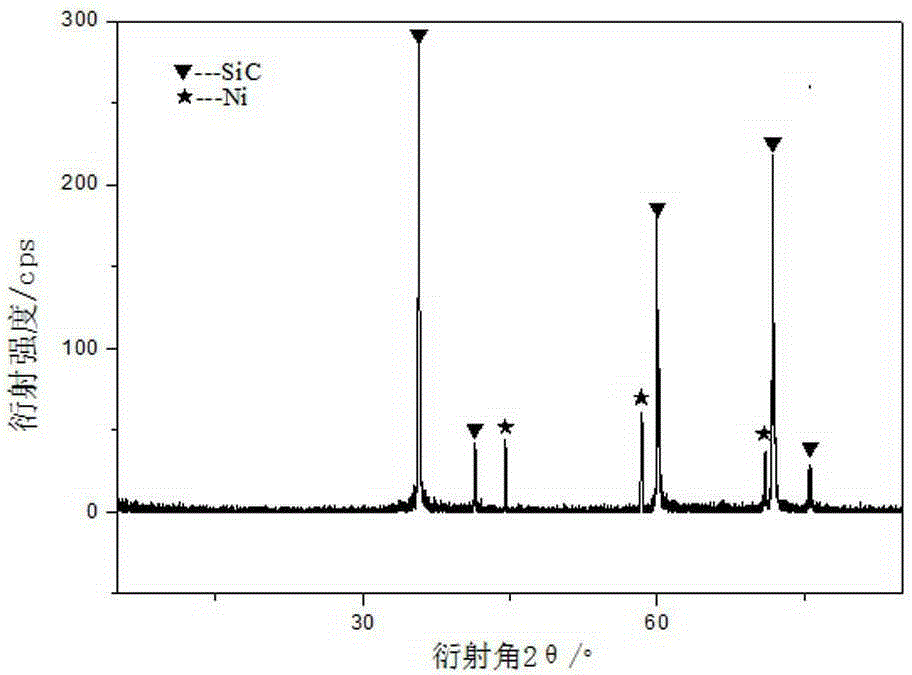

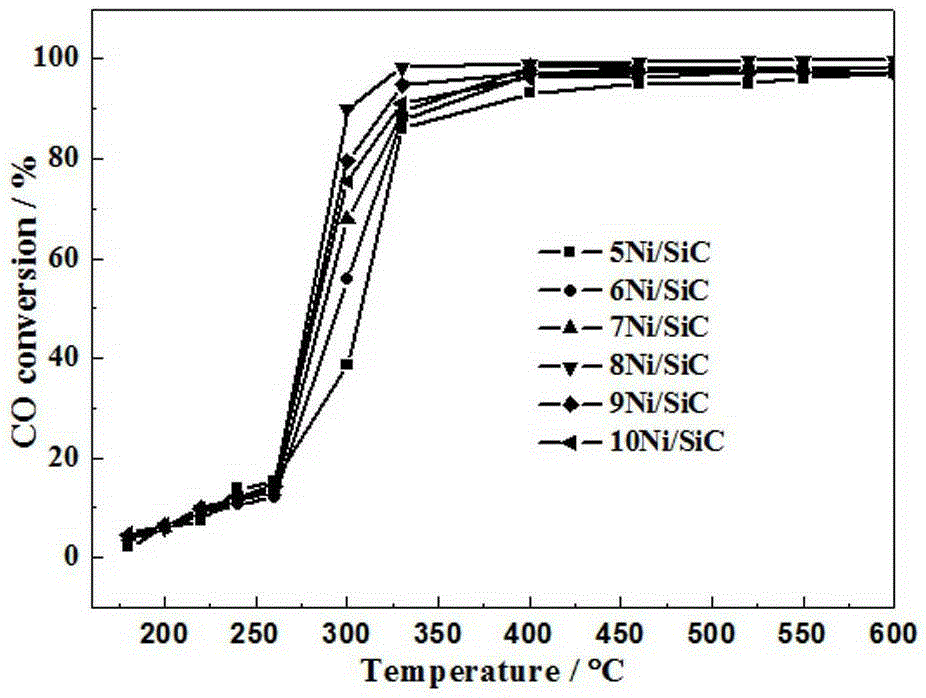

Image

Examples

Embodiment Construction

[0040] The chemical substance material that the present invention uses is: silicon dioxide, gac, nickel nitrate, hydrofluoric acid, nitric acid, deionized water, nitrogen, and its preparation consumption takes gram, milliliter, centimeter as unit of measurement:

[0041]

[0042] Select and control the quality, purity and concentration of the chemical substances required for preparation:

[0043]

[0044] (1) Prepare the mixture

[0045] ①Dry activated carbon

[0046] Weigh 60g±0.001g of wood-based activated carbon and put it in an oven at 100°C to dry for 12h.

[0047] ② Grinding activated carbon

[0048] Put the dried activated carbon into the agate ball mill jars and seal them, set the ball milling speed to 500 rpm, and take forward rotation and reverse rotation for 5 minutes each as a ball milling cycle, and run for three cycles.

[0049] ③Sieving

[0050] Sieve the ground activated carbon with a 200-mesh sieve, retain the activated carbon powder, and store it fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com