Unsaturated siloxane group phosphate emulsion concrete curing agent and preparation method thereof

A technology of siloxane-based phosphate ester and concrete curing agent, which is applied in the field of building materials, and can solve the problems of difficulty in grasping the spraying time of polymer solution and paraffin emulsion curing agent, low adhesion strength of concrete surface, and low water retention rate of water glass curing agent and other problems, to achieve the effect of easy industrial production, simplification of construction procedures, and prevention of capillary channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

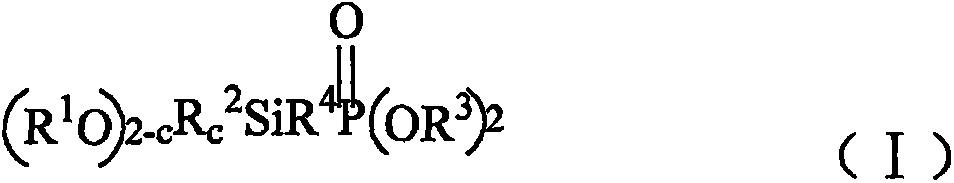

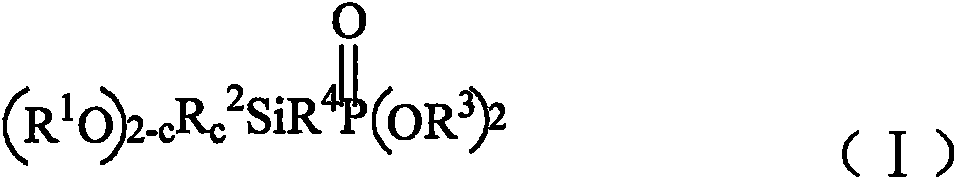

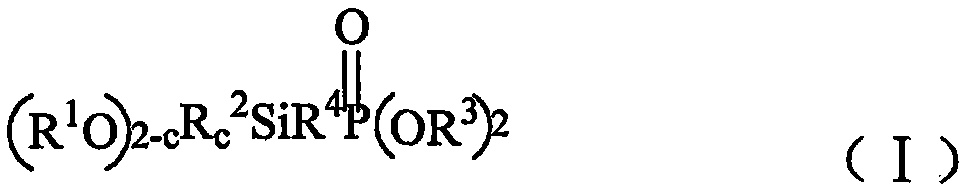

Method used

Image

Examples

Embodiment 1

[0043] The first step: add 300g water in the reactor, non-ionic emulsifier alkylphenol polyoxyethylene ether (OP-10) 13.5g, sodium lauryl sulfate 1.5g, p-toluenesulfonic acid 1.50g, under stirring Heat to 80°C, add 95g of vinylmethylene organosiloxane phosphate, 50g of acrylic acid and 32g of methyl acrylate mixture dropwise within three hours, and at the same time add dropwise 1.74g of persulfuric acid within 3.5 hours Potassium aqueous solution 87g, the solution was added dropwise and the reaction was continued for 1 hour at 80°C. Cool down to get 500g of curing agent emulsion.

[0044] The second step: take 50g of the polymer emulsion synthesized in the first step above, add 1g of propylene glycol butyl ether film-forming aid, 1g of polyether defoamer, 5g of cellulose ether thickener, 3g of silicone leveling agent and 40g Water to prepare a high-performance concrete curing agent, its solid content is 24%, and its 72h water retention rate is 75%.

Embodiment 2

[0046] The first step: add 300g water in the reactor, non-ionic emulsifier alkylphenol polyoxyethylene ether (OP-10) 13.5g, sodium lauryl sulfate 1.5g, p-toluenesulfonic acid 1.50g, under stirring Heat to 80°C, add 95g of vinyl ethylene organosiloxane phosphate, 50g of acrylic acid and 32g of methyl acrylate mixture dropwise within 3 hours, and add 1.74g of persulfuric acid in 3.5 hours at the same time Potassium aqueous solution 87g, the solution was added dropwise and the reaction was continued for 1 hour at 80°C. Cool down to get 500g of curing agent emulsion.

[0047] The second step: take 50g of the polymer emulsion synthesized in the first step above, add 1g of propylene glycol butyl ether film-forming aid, 1g of polyether defoamer, 5g of cellulose ether thickener, 3g of silicone leveling agent and 40g Water to prepare a high-performance concrete curing agent, its solid content was 24% in the test, and its water retention rate was 90% in 72 hours.

Embodiment 3

[0049] The first step: add 300g water in the reactor, non-ionic emulsifier alkylphenol polyoxyethylene ether (OP-10) 13.5g, sodium lauryl sulfate 1.5g, p-toluenesulfonic acid 1.50g, under stirring Heat to 80°C, add 95g of vinyl butylene organosiloxane phosphate, 50g of acrylic acid and 32g of methyl acrylate mixture dropwise within 3 hours, and at the same time add 1.74g of potassium persulfate in 3.5 hours 87g of the aqueous solution, the solution was added dropwise and the reaction was continued for 1 hour at 80°C. Cool down to get 500g of curing agent emulsion.

[0050] The second step: take 50g of the polymer emulsion synthesized in the first step above, add 1g of propylene glycol butyl ether film-forming aid, 1g of polyether defoamer, 5g of cellulose ether thickener, 3g of silicone leveling agent and 40g Water, made high-performance concrete curing agent, its solid content was 24% in the test, and the 72h water retention rate was 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com