Anaerobic pipe thread sealant and preparation method thereof

A pipe thread and sealant technology, which is applied in the field of paste sealant and its preparation, can solve the problems of incomplete curing, decreased medium resistance, and decreased sealing performance, and achieves low cost, stable performance, and improved liquid precipitation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

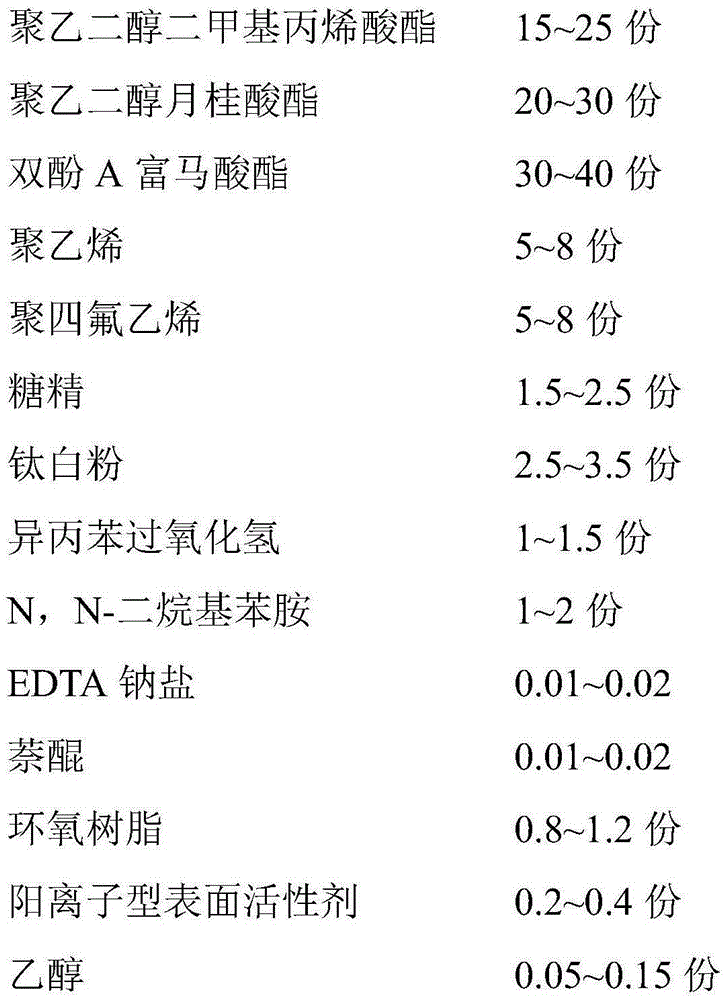

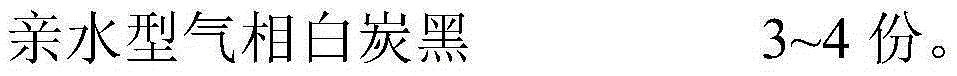

Method used

Image

Examples

Embodiment 1

[0032] 19 parts of polyethylene glycol dimethacrylate oligomer, 22 parts of polyethylene glycol laurate, 1.9 parts of saccharin, 1.5 parts of N, N-dimethylaniline, 0.015 parts of EDTA sodium salt, 0.015 parts of naphthalene Put the quinone into the reaction kettle, and stir it for 1 hour at a speed of 300 rpm until it is completely dissolved. Add 32 parts of bisphenol A fumarate, and stir for 2 hours at 800 rpm until completely dissolved. Then add 7 parts of polytetrafluoroethylene powder, and stir for 30 minutes at a speed of 1000 rpm until the mixture is evenly dispersed. Then add 7 parts of polyethylene powder, 3 parts of titanium dioxide, and 1 part of epoxy resin, and stir for 300 minutes at a speed of 800 to 1000 rpm to disperse evenly. Then add 1.2 parts of cumene hydroperoxide, and stir at a speed of 1000 rpm for 30 minutes until the mixture is uniformly dispersed, and the temperature of the material is controlled below 50° C. during stirring. Add 2.5 parts and the s...

Embodiment 2

[0034] 20 parts of polyethylene glycol dimethacrylate oligomer, 23 parts of polyethylene glycol laurate, 2 parts of saccharin, 1.6 parts of N, N-dimethylaniline, 0.017 parts of EDTA sodium salt, 0.016 parts of naphthalene Put the quinone into the reaction kettle, and stir it for 1 hour at a speed of 300 rpm until it is completely dissolved. Then add 33 parts of bisphenol A fumarate, and stir for 2 hours at a speed of 800 rpm until completely dissolved. Then add 7.5 parts of polytetrafluoroethylene powder, and stir for 30 minutes at a speed of 1000 rpm until the mixture is evenly dispersed. Then add 6.8 parts of polyethylene powder, 2.5 parts of titanium dioxide, and 0.8 parts of epoxy resin, and stir for 300 minutes at a speed of 800 to 1000 rpm to disperse evenly. Then add 1 part of cumene hydroperoxide, and stir at a speed of 1000 rpm for 30 minutes until the mixture is uniformly dispersed, and the temperature of the material is controlled below 50° C. during stirring. Add...

Embodiment 3

[0036] 21 parts of polyethylene glycol dimethacrylate oligomer, 22 parts of polyethylene glycol laurate, 1.8 parts of saccharin, 1.5 parts of N, N-dimethylaniline, 0.015 parts of EDTA sodium salt, 0.01 part of naphthalene Put the quinone into the reaction kettle, and stir it for 1 hour at a speed of 300 rpm until it is completely dissolved. Then add 34 parts of bisphenol A fumarate, and stir for 2 hours at a speed of 800 rpm until completely dissolved. Then add 7 parts of polytetrafluoroethylene powder, and stir for 30 minutes at a speed of 1000 rpm until the mixture is evenly dispersed. Then add 6.2 parts of polyethylene powder, 2.3 parts of titanium dioxide, and 0.9 parts of epoxy resin, and stir for 300 minutes at a speed of 800 to 1000 rpm to disperse evenly. Then add 1 part of cumene hydroperoxide, and stir at a speed of 1000 rpm for 30 minutes until the mixture is uniformly dispersed, and the temperature of the material is controlled below 50° C. during stirring. Add 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com