A method for separating and immobilizing multiple enzymes

A mass percentage content and coating technology, which is applied to multi-enzyme systems, fixed on/in organic carriers, etc., can solve the problems that the reaction cannot be carried out as scheduled, so as to maintain activity, realize simple recycling, and react The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

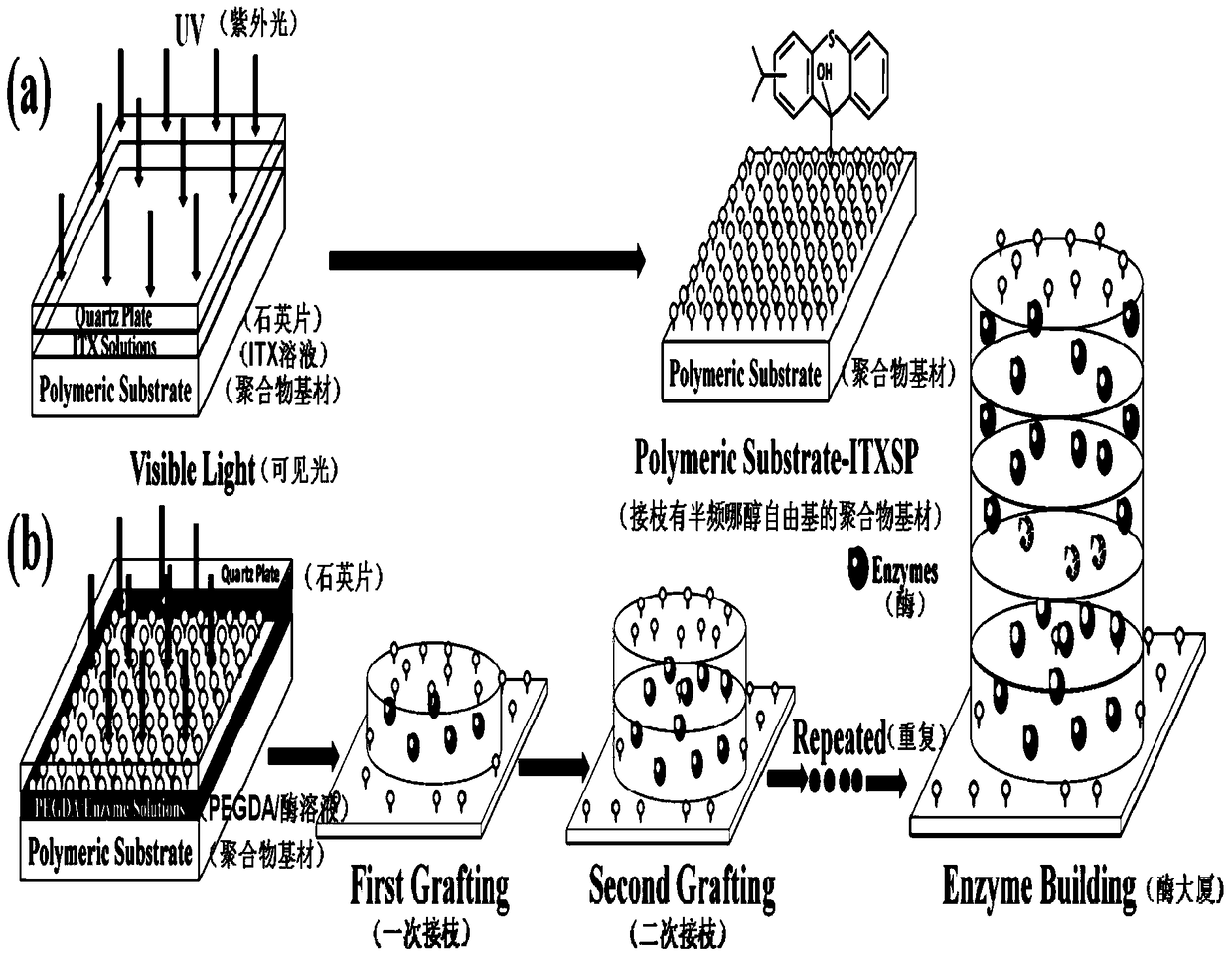

Method used

Image

Examples

Embodiment 1

[0033] Spread 40 μL, 3 mmol / mL of isopropylthioxanthone acetone solution evenly on 3 × 3 cm 2 One side of the low-density polyethylene film, and then the film coated with the solution was placed between two quartz plates, and then the system was placed in a high-pressure mercury lamp (wavelength 254nm, 9mW / cm 2 ) at room temperature for 3 minutes. After the ultraviolet irradiation, the low-density polyethylene film was extracted with acetone for 24 hours, and dried at room temperature.

[0034]Dissolve a certain amount of trypsin in 0.1M Tris-HCl (pH=7.0) buffer solution, shake and dissolve to form a 11.5 mg / mL trypsin solution, and mix this solution with polyethylene glycol diacrylate according to 75: After mixing at 45 (v / v), take 60 μL and apply it on one side of the low-density polyethylene film grafted with isopropylthioxanthone, and then place the film coated with the solution on two pieces with patterned Between the masks in the light-transmitting area, the system was...

Embodiment 2

[0043] Spread 600 μL, 5 mmol / mL isopropylthioxanthone acetone solution evenly on 3×3 cm 2 One side of the polypropylene non-woven fabric, and then the solution-coated non-woven fabric is arranged between two quartz plates, and then the system is placed in a high-pressure mercury lamp (light intensity is 5mW / cm 2 ) at room temperature for 5 minutes. After the ultraviolet irradiation, the non-woven fabric was extracted with acetone for 24 hours, and dried at room temperature.

[0044] Dissolve a certain amount of papain in 0.1M Tris-HCl (pH=7.0) buffer, shake and dissolve to form a 10 mg / mL papain solution, and mix this solution with polyethylene glycol dimethacrylate according to 1 : 1 (v / v) after mixing, take 800μL and apply it on one side of the non-woven fabric grafted with isopropylthioxanthone, and then arrange the non-woven fabric coated with the solution between two quartz plates time, and then put the system under LED lamp (light intensity 0.5mW / cm 2 ) under irradiat...

Embodiment 3

[0051] Spread 300 μL, 2 mmol / mL isopropylthioxanthone acetone solution evenly on 4×4 cm 2 cotton cloth, and then the cotton coated with the solution was arranged between two quartz plates, and then the system was placed in a high-pressure mercury lamp (the light intensity was 1mW / cm 2 ) at room temperature for 10 minutes. After the ultraviolet irradiation, the cotton cloth was extracted with acetone for 24 hours and dried at room temperature.

[0052] Dissolve a certain amount of glucose oxidase in 0.1M Tris-HCl (pH=7.0) buffer solution, shake and dissolve to form a 10 mg / mL glucose oxidase solution, and mix this solution with methylenebisacrylamide according to 2: 1 (v / v) after mixing, take 500 μL and apply it on one side of the cotton cloth grafted with isopropylthioxanthone, then arrange the cotton coated with the solution between two quartz plates, and then place the The system was placed in a xenon lamp (light intensity 2mW / cm 2 ) under irradiation for 60 minutes. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com