Method for improving oil content of oil-producing microalgae based on fulvic acid

A technology for oil content, oil-producing microalgae, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to achieve the effects of small molecular weight, growth promotion and oil accumulation, and high functional group content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

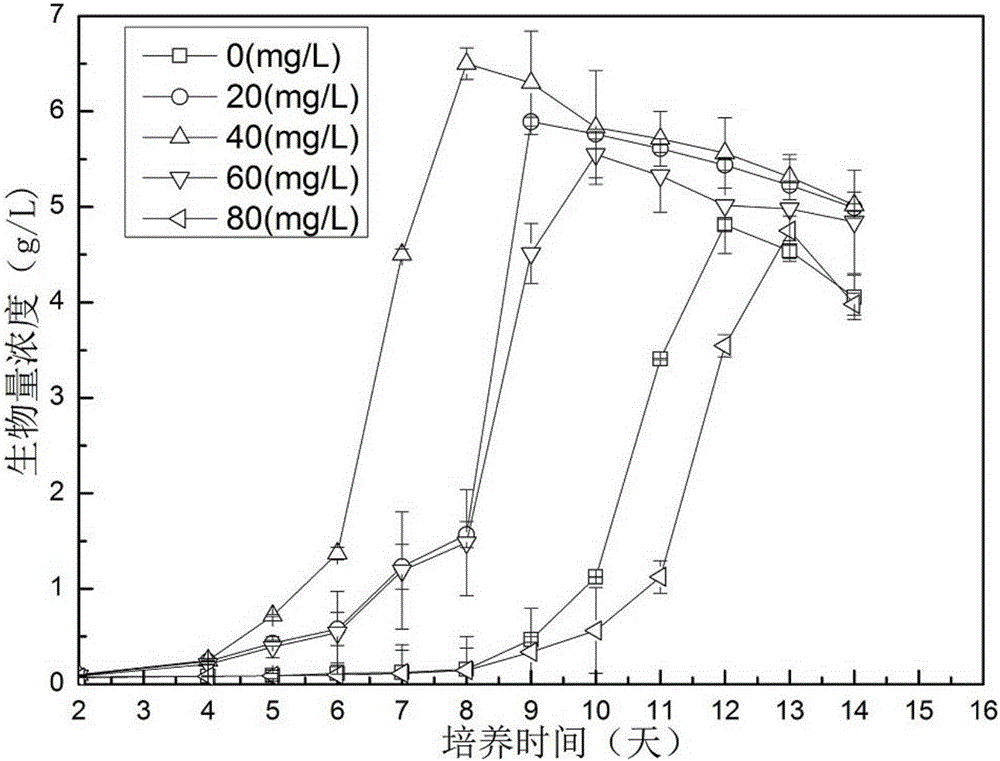

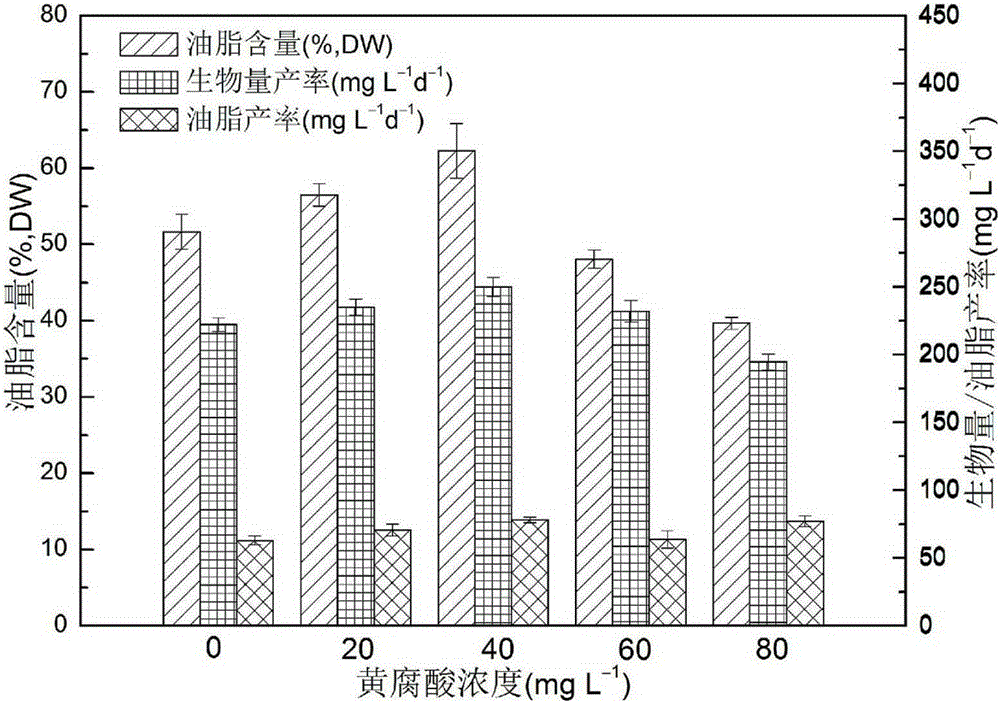

[0026] Fulvic acid improves biomass and oil production experiment in BG-11 medium, comprises the following steps:

[0027] (1) Select the BG-11 medium (China Freshwater Algae Species Bank) as the basic medium of Monostifles, put it in a 500mL triangular flask, add glucose in an amount of 10g / L as a carbon source, and add fulvic acid Dissolved in ultrapure water and configured as a mother solution of 1000mg / L, the concentration of fulvic acid in the medium is 20mg / L, and the pH value is adjusted to 6.8.

[0028] (2) High-pressure high-temperature sterilization for 20 minutes, inserting Monopodella oleaginum, and controlling the cell density of the algae at 10 6 cells / mL, cultured in shake flasks, the culture temperature was 23°C, the shaker speed was 130r / min, and cultured in the dark.

[0029] (3) The final culture medium of each group was enriched by centrifugation (3000r / min, 6min), washed twice with distilled water, freeze-dried and weighed. Add 2 times the mass of freeze...

Embodiment 2

[0031] Fulvic acid improves biomass and oil production experiment in BG-11 medium, comprises the following steps:

[0032] (1) Select the BG-11 medium (China Freshwater Algae Species Bank) as the basic medium of Monostifles, put it in a 500mL triangular flask, add glucose in an amount of 10g / L as a carbon source, and add fulvic acid Dissolved in ultrapure water and configured as a mother solution of 1000mg / L, the concentration of fulvic acid in the medium is 40mg / L, and the pH value is adjusted to 6.9.

[0033] (2) High-pressure high-temperature sterilization for 20 minutes, inserting Monopodella oleaginum, and controlling the cell density of the algae at 10 6 cells / mL, cultured in shake flasks, the culture temperature was 24°C, the shaker speed was 140r / min, and cultured in the dark.

[0034] (3) The final culture medium of each group was enriched by centrifugation (3000r / min, 6min), washed twice with distilled water, freeze-dried and weighed. Add 2 times the mass of freeze...

Embodiment 3

[0036] Fulvic acid improves biomass and oil production experiment in BG-11 medium, comprises the following steps:

[0037] (1) Select the BG-11 medium (China Freshwater Algae Species Bank) as the basic medium of Monostifles, put it in a 500mL triangular flask, add glucose in an amount of 10g / L as a carbon source, and add fulvic acid Dissolved in ultrapure water and configured as a mother solution of 1000mg / L, the concentration of fulvic acid in the medium is 60mg / L, and the pH value is adjusted to 7.

[0038] (2) High-pressure high-temperature sterilization for 20 minutes, inserting Monopodella oleaginum, and controlling the cell density of the algae at 10 6 cells / mL, cultured in shake flasks, the culture temperature was 25°C, the shaker speed was 150r / min, and cultured in the dark.

[0039] (3) The final culture medium of each group was enriched by centrifugation (3000r / min, 6min), washed twice with distilled water, freeze-dried and weighed. Add 2 times the mass of freeze-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com