Preparation method for sample of aluminum-based graphene thermal conductive composite

A heat-conducting composite material and graphene technology, applied in the direction of coating, etc., to achieve the effects of improving non-compactness, rapid and effective preparation, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

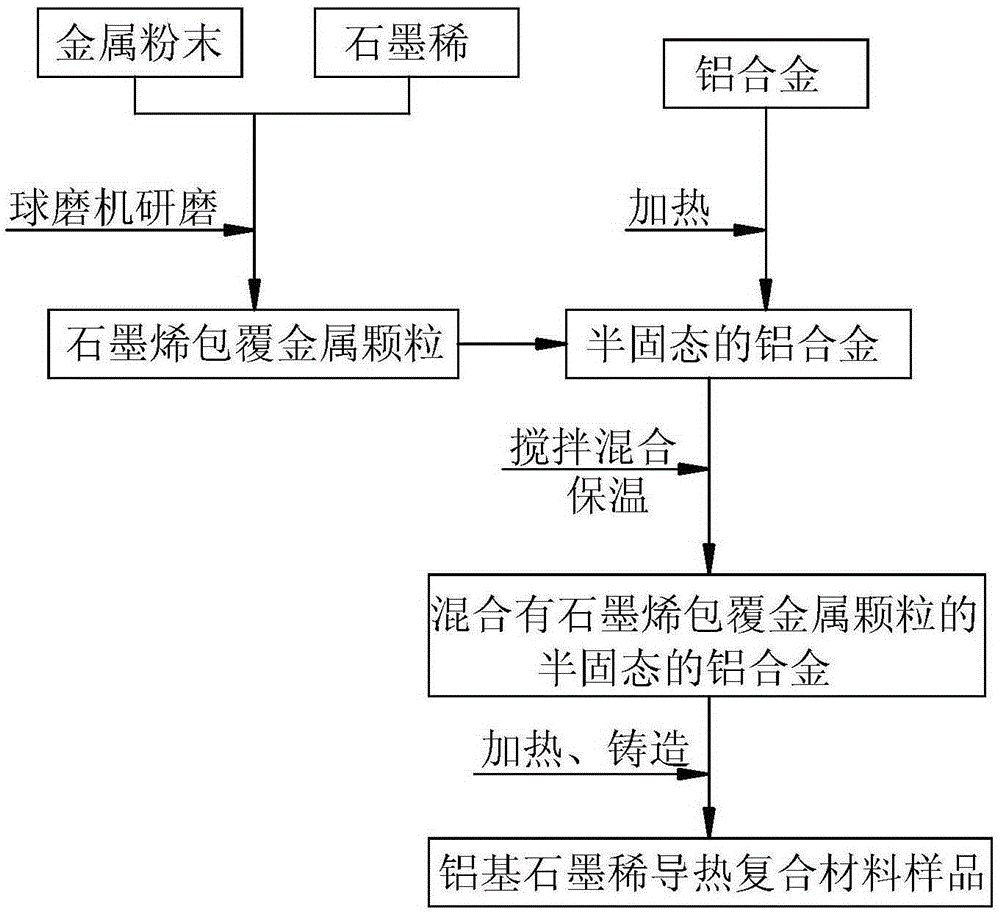

[0028] For the preparation of 1# aluminum-based graphene thermally conductive composite material samples, refer to figure 1 :

[0029] Put 5g of graphene with a particle size of 10μm, 250g of pure aluminum powder with a particle size of 100μm, and 1.25g of stearic acid into a planetary ball mill, and grind for 6 hours at 400 rpm to obtain a graphene-coated metal Then take 250g of pure aluminum and heat it to 580°C to become semi-solid and stir it, add all the graphene-coated metal particles, heat and stir for 2 hours, quickly raise the temperature to 720°C to make the aluminum alloy into a liquid state, and cast it immediately to obtain 1# aluminum-based graphene thermal conductivity composite material sample. The thermal conductivity of the 1# aluminum-based graphene thermally conductive composite sample is 250W / mK.

Embodiment 2

[0031] Preparation of 2# aluminum-based graphene thermal conductivity composite material sample:

[0032] This embodiment is basically the same as Embodiment 1, except that the mass of graphene is 0.5 g. The thermal conductivity of the 2# aluminum-based graphene thermally conductive composite sample is 210W / mK.

Embodiment 3

[0034] Preparation of 3# aluminum-based graphene thermal conductivity composite material sample:

[0035] This embodiment is basically the same as Embodiment 1, the difference being that the mass of graphene is 15g. The thermal conductivity of the 3# aluminum-based graphene thermally conductive composite sample is 270W / mK.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com