Non-phosphorous water-based degreasing agent used in non-phosphorous coating pretreatment

A pre-treatment and degreasing agent technology, applied in the field of phosphorus-free water-based degreasing agent, can solve the problems affecting the coating appearance, adhesion performance and corrosion resistance, and the influence of subsequent processes, so as to achieve strong solubility and improve cleaning power , The effect of long-lasting low foam performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

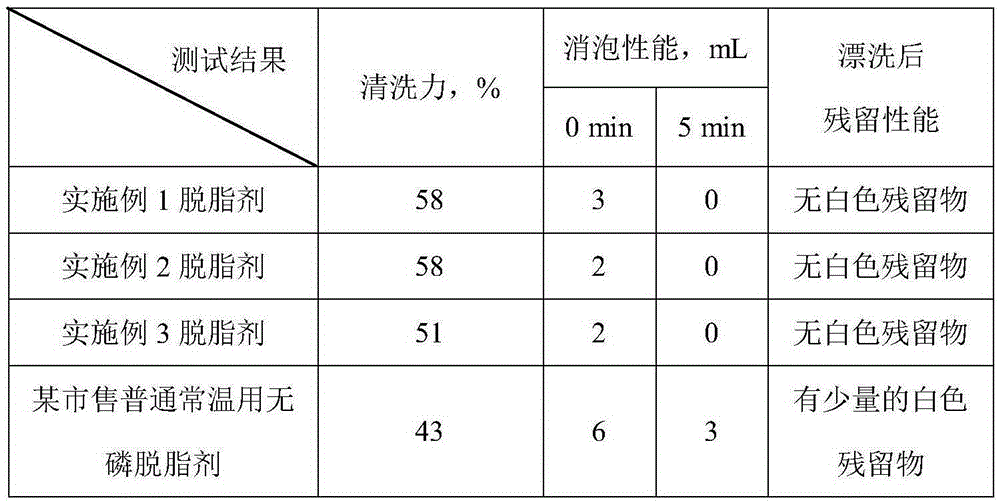

Examples

Embodiment 1

[0015] A phosphorus-free water-based degreasing agent used in the pre-treatment of phosphorus-free painting, which is formulated from the following components by weight percentage: 20% monoethanolamine; 2% sodium gluconate, 4% sodium citrate, 2% tetrasodium edetate; 1% sodium carboxymethyl cellulose, 1% sodium lignosulfonate; 5% fatty alcohol polyoxyethylene ether, 5% isomeric alcohol polyoxyethylene ether , 5% fatty alcohol polyoxyethylene polyoxypropylene ether; 5% carboxylate, 5% alkyl glycoside; 3% polyether defoamer and water balance.

[0016] First add the required amount of water into the stirring tank, while stirring, sequentially add the required amount of monoethanolamine, sodium gluconate, sodium citrate, tetrasodium edetate, sodium carboxymethyl cellulose, lignin sulfonate Sodium acid sodium, fatty alcohol polyoxyethylene ether, isomeric alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene polyoxypropylene ether, carboxylate, alkyl glycoside and polyether d...

Embodiment 2

[0018] A phosphorus-free water-based degreasing agent used in the pretreatment of phosphorus-free painting, which is prepared from the following components by weight percentage: 10% monoethanolamine, 4% triethanolamine, 4% 2-amino-2 Methyl-1-propanol; 6% sodium gluconate; 1% polyvinylpyrrolidone; 5% octylphenol ethoxylate, 5% fatty alcohol polyoxyethylene ether, 5% fatty alcohol polyoxyethylene Ethylene polyoxypropylene ether; 5% carboxylate; 0.02% polyether defoamer and the balance of water.

[0019] First add the required amount of water into the stirring tank, while stirring, sequentially add the required amount of monoethanolamine, triethanolamine, 2-amino-2methyl-1-propanol, sodium gluconate, sodium carboxymethylcellulose , octylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene polyoxypropylene ether, carboxylate and polyether defoamer are added to the stirring tank, and fully stirred until the mixed solution becomes uniform ...

Embodiment 3

[0020] A phosphorus-free water-based degreasing agent used in the pre-treatment of phosphorus-free painting, which is formulated from the following components by weight percentage: 5% monoethanolamine; 1% sodium gluconate; 10% alkylolamide ; 1% nonylphenol polyoxyethylene ether, 1% fatty alcohol polyoxyethylene polyoxypropylene ether; 5% alkyl glycoside; 0.01% polyether modified silicon defoamer and water balance.

[0021] First add the required amount of water into the stirring tank, while stirring, sequentially add the required amount of monoethanolamine, sodium gluconate, alkyl alcohol amide, nonylphenol polyoxyethylene ether, fatty alcohol polyoxyethylene polyoxypropylene ether , alkyl glucoside and polyether modified silicon defoamer are added into the stirring tank, fully stirred until the mixed solution becomes uniform and transparent, and the uniform and transparent mixed solution is the phosphorus-free water-based degreasing agent of the present invention. This degrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com