Novel sponge body double-waste pervious concrete pavement

A technology of permeable concrete and sponge, applied in solid waste management, on-site coagulation pavement, roads, etc., can solve the problems of urban surface water natural environment damage, water loss of self-purification function, poor pressure resistance, etc., to prevent The effect of depleting groundwater, reducing surface water runoff, and saving engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

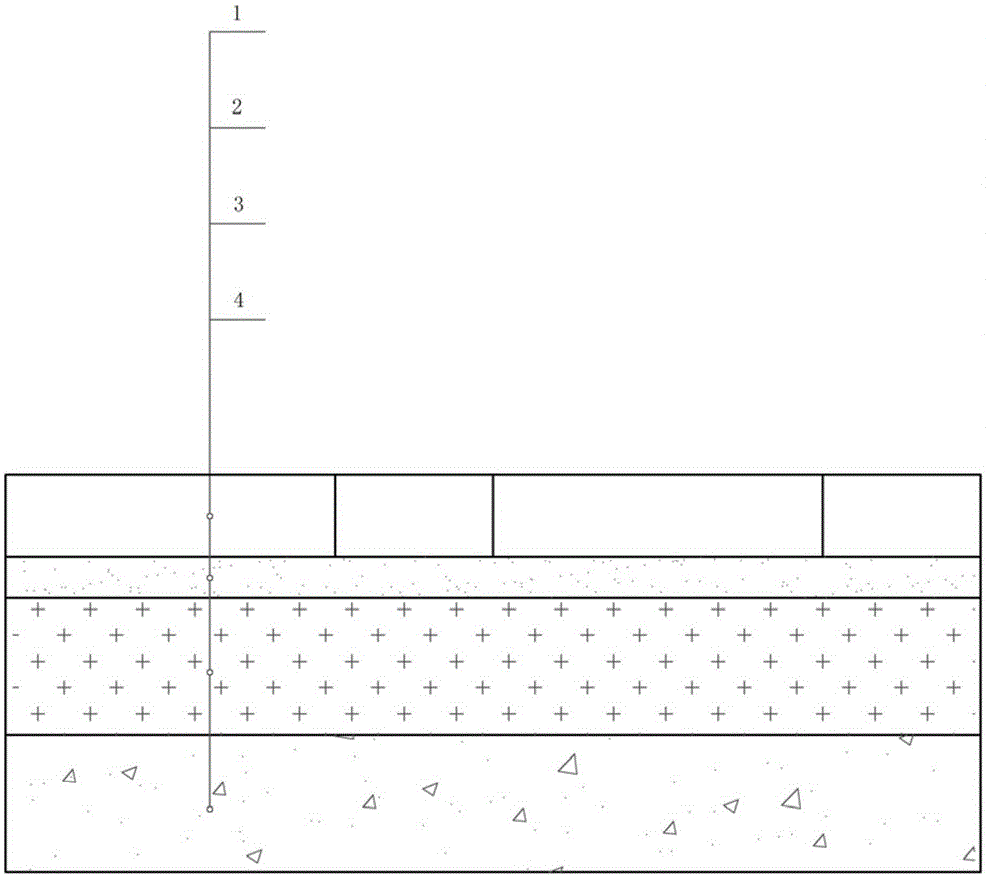

[0041] Such as figure 1 As shown, the new spongy double-waste permeable concrete pavement in this embodiment includes a surface layer 1, a connecting layer 2, a base layer 3 and a cushion layer 4 connected in sequence. Surface layer 1 is 200×100×60mm 3 Concrete permeable bricks; the connecting layer 2 is spongy garden waste mortar with a thickness of 30mm and a compressive strength of 15MPa; the base layer 3 is a new type of spongy double-waste permeable concrete with a thickness of 100mm and a compressive strength of 20MPa; the cushion layer 4 is 100mm Thick gravel bedding.

[0042] The garden waste in the spongy garden waste mortar is crushed fragmented garden waste and the garden waste comes from branches, leaves, and bark. Sponge garden waste mortar is a mortar made by uniformly mixing cement, sand, fragmented garden waste and water, and its weight ratio is: cement: sand: fragmented garden waste: water The weight ratio is 100 :200:10:45. Among them, the cement is 42.5 ...

Embodiment 2

[0045] Not shown graphically. The new spongy double-waste permeable concrete pavement in this embodiment includes a surface layer, a connecting layer, a base layer and a cushion layer connected in sequence. Surface layer is 200×100×60mm 3 The concrete permeable brick; the connecting layer is spongy garden waste mortar with a thickness of 30mm and a compressive strength of 15MPa; the base layer is a new type of spongy double-waste permeable concrete with a thickness of 100mm and a compressive strength of 25MPa; the cushion layer is a 100mm thick crushed Stone cushion.

[0046] The garden waste in the spongy garden waste mortar is crushed and fragmented garden waste, and the garden waste comes from wood chips and sawdust. Sponge garden waste mortar is a mortar made by uniformly mixing cement, sand, fragmented garden waste and water, and its weight ratio is: cement: sand: fragmented garden waste: water The weight ratio is 100 :300:40:60. Among them, the cement is 52.5 ordinar...

Embodiment 3

[0048] Not shown graphically. The new spongy double-waste permeable concrete pavement in this embodiment includes a surface layer, a connecting layer, a base layer and a cushion layer connected in sequence. Surface layer is 200×100×60mm 3 The concrete permeable brick; the connecting layer is spongy garden waste mortar with a thickness of 30mm and a compressive strength of 15MPa; the base layer is a new type of spongy double-waste permeable concrete with a thickness of 100mm and a compressive strength of 20MPa; the cushion layer is a 100mm thick crushed Stone cushion.

[0049] The garden waste in the spongy garden waste mortar is crushed fragmented garden waste and the garden waste comes from straw. The spongy garden waste mortar is made by uniformly mixing cement, sand, fragmented garden waste and water, and its weight ratio is: cement: sand: fragmented garden waste: the weight ratio of water is 100:220:25:50. Among them, the cement is aluminate cement; the sand is medium-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com