Laminate, protective film and mehod for manufacturing laminate

A manufacturing method and laminated body technology, applied to chemical instruments and methods, film/sheet adhesives, protective clothing, etc., can solve the problems of insufficient research on practical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

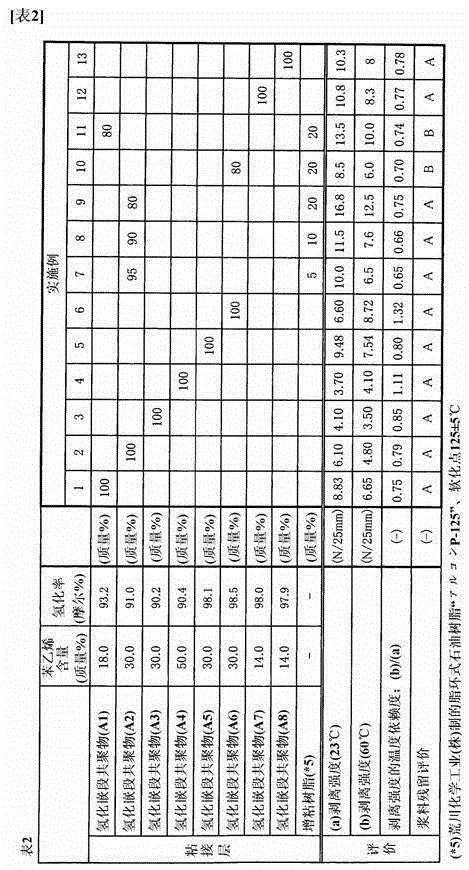

Examples

Embodiment

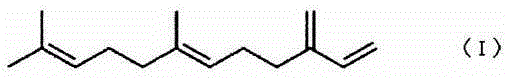

[0134] The present invention will be described below by way of examples, but the present invention is not limited to these examples. In addition, β-farnesene (purity 97.6 mass %, manufactured by Amyris Biotechnology Co., Ltd.) was purified by 3 A molecular sieve, and distilled in a nitrogen atmosphere to remove zingiberene, bisabolene, epoxyfarnesene, Hydrocarbon impurities such as farnesol isomers, E,E-farnesol, squalene, ergosterol, and dimers of several types of farnesene are used for the following polymerization.

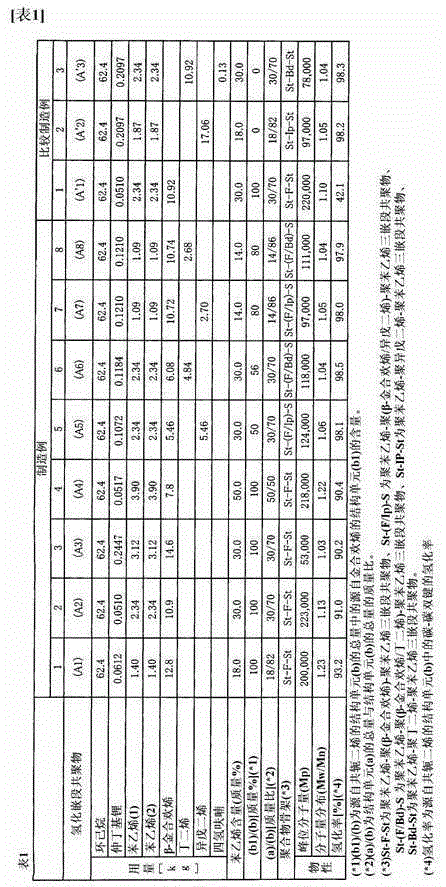

[0135] (1) Determination of molecular weight distribution (Mw / Mn) and peak molecular weight (Mp)

[0136] The weight-average molecular weight (Mw) and molecular weight distribution (Mw / Mn) of the hydrogenated block copolymers obtained in the respective Examples and Comparative Examples were determined by GPC (gel permeation chromatography) in terms of molecular weight in terms of standard polystyrene. In addition, the position of the apex of the peak of the mol...

manufacture example 1

[0166]

[0167] 62.4 kg of cyclohexane as a solvent and 61.2 g of sec-butyllithium (10.5% by mass cyclohexane solution) as an anionic polymerization initiator were added to a pressure vessel that had been replaced with nitrogen and dried, and after heating up to 50°C, added Styrene (1) 1.40 kg was polymerized for 1 hour, then 12.8 kg of β-farnesene was added, and 1 hour of polymerization was carried out, and then 1.40 kg of styrene (2) was added, and 1 hour of polymerization was carried out, thus obtaining a compound containing polystyrene- Reaction solution of poly(β-farnesene)-polystyrene triblock copolymer. 5% by mass of palladium on carbon (supported palladium: 5% by mass) as a hydrogenation catalyst was added to the reaction liquid, and the reaction was carried out under a hydrogen pressure of 2 MPa and 150° C. for 10 hours. After natural cooling and decompression, the palladium carbon was removed by filtration, the filtrate was concentrated, and further vacuum-dried to...

manufacture example 2

[0168] [Manufacturing example 2]~[Manufacturing example 4]

[0169]

[0170] The hydrogenated block copolymers (A2) to (A4) were obtained in the same manner as in Production Example 1 except that the compounding of various raw materials was changed to that described in Table 1. Table 1 shows the measurement results of various physical properties of the obtained hydrogenated block copolymers (A2) to (A4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com