One-component polyurethane adhesive and preparing method thereof

A polyurethane adhesive, one-component technology, applied in the direction of adhesive additives, non-polymer adhesive additives, etc., can solve the problems of performance degradation, poor water resistance and heat resistance, etc., to improve compatibility, improve Heat resistance and water resistance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

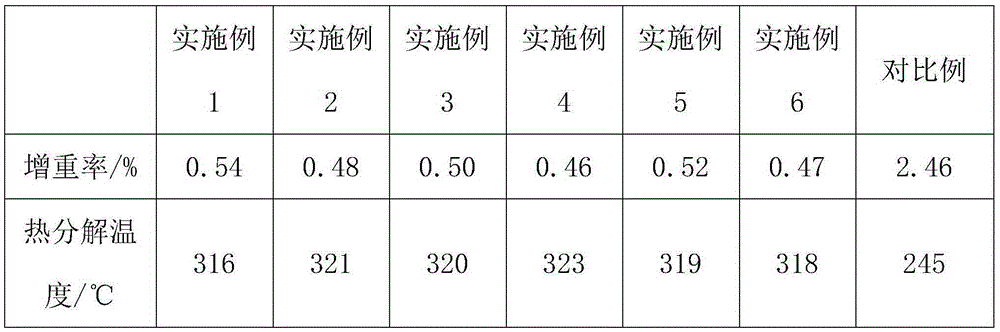

Examples

Embodiment 1

[0026] One-component polyurethane adhesive, its components and parts by weight are: 45 parts of vegetable oil polyol, 23 parts of MDI, 0.1 part of triethanolamine, 12 parts of DIDP, 0.05 parts of organotin catalyst, 14 parts of chlorinated hydrocarbons, rosin glyceride 10 parts, 1.2 parts of trimethylolpropane, 7.5 parts of titanium diboride, 9.3 parts of PES.

[0027] The steps of its preparation method are as follows:

[0028] (1) Add the silane coupling agent to deionized water and stir evenly to obtain a coupling agent solution with a concentration of 12%. After adjusting the pH value to 3.2 with hydrochloric acid, add titanium diboride powder, and the silane coupling agent and diboride The weight ratio of the titanium powder is 1:24, put it into an ultrasonic cleaner for ultrasonic dispersion for 30 minutes, let it settle for 10 hours and then centrifuge it, wash the precipitate and dry it to a constant weight at 90°C, and grind it to obtain the modified titanium powder. ...

Embodiment 2

[0032] One-component polyurethane adhesive, its components and parts by weight are: 40 parts of vegetable oil polyols, 25 parts of MDI, 0.4 parts of triethanolamine, 10.5 parts of DINP, 0.06 parts of organotin catalysts, 11 parts of chlorinated hydrocarbons, rosin 8.5 parts of glyceride, 1.6 parts of trimethylolpropane, 7 parts of titanium diboride, 9.6 parts of PES.

[0033] The steps of its preparation method are as follows:

[0034] (1) Add the silane coupling agent to deionized water and stir evenly to obtain a coupling agent solution with a concentration of 12%. After adjusting the pH value to 3.2 with hydrochloric acid, add titanium diboride powder, and the silane coupling agent and diboride The weight ratio of the titanium powder is 1:24, put it into an ultrasonic cleaner for ultrasonic dispersion for 30 minutes, let it settle for 10 hours and then centrifuge it, wash the precipitate and dry it to a constant weight at 90°C, and grind it to obtain the modified titanium p...

Embodiment 3

[0038] One-component polyurethane adhesive, its components and parts by weight are: 60 parts of vegetable oil polyols, 20 parts of MDI, 0.2 parts of triethanolamine, 11.5 parts of DIDP, 0.04 parts of organic tin catalysts, 13 parts of chlorinated hydrocarbons, rosin 8.8 parts of glyceride, 1 part of trimethylolpropane, 6.5 parts of titanium diboride, 9 parts of PES.

[0039] The steps of its preparation method are as follows:

[0040] (1) Add the silane coupling agent to deionized water and stir evenly to obtain a coupling agent solution with a concentration of 12%. After adjusting the pH value to 3.2 with hydrochloric acid, add titanium diboride powder, and the silane coupling agent and diboride The weight ratio of the titanium powder is 1:24, put it into an ultrasonic cleaner for ultrasonic dispersion for 30 minutes, let it settle for 10 hours and then centrifuge it, wash the precipitate and dry it to a constant weight at 90°C, and grind it to obtain the modified titanium po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com