Electromagnetic shielding material and nano-grade composite material thereof, and preparation methods thereof

A technology of electromagnetic shielding materials and carbon nanotubes, applied in chemical instruments and methods, and other chemical processes, to achieve the effects of low toxicity, strong applicability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, preparation electromagnetic shielding-polymer nanocomposite material

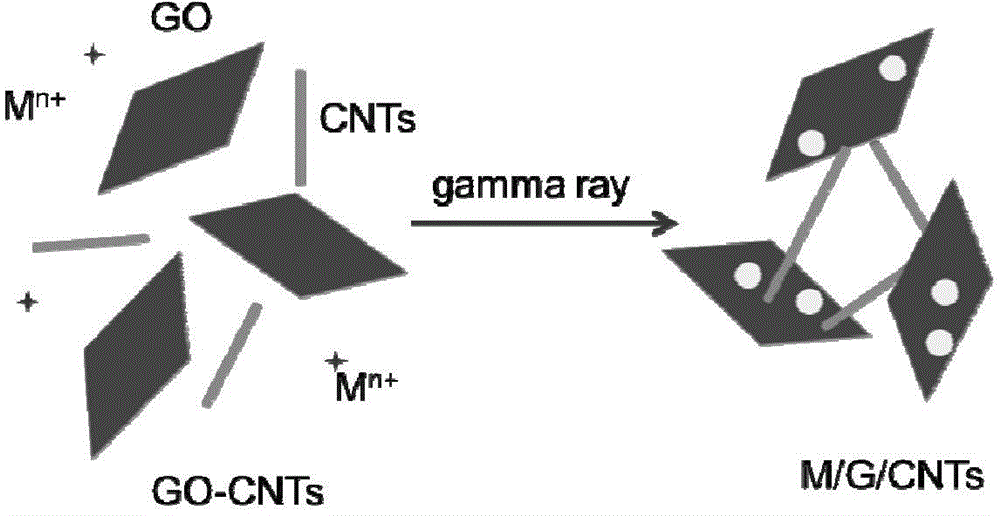

[0042] 1) Preparation of metal nanoparticles / graphene / carbon nanotubes three-dimensional network structure electromagnetic shielding materials

[0043] 100mg of graphene oxide and 100mg of single-walled carbon nanotubes (4nm in diameter and 30μm in length) were ultrasonically dispersed in 200mL of N,N-dimethylformamide solution (1mg / mL), and ultrasonically exfoliated at 25°C Disperse for 1h (ultrasonic power 450W) to obtain graphene oxide / carbon nanotube solution; subsequently, add 116mgNi(NO 3 ) 2 ·6H 2 O (added in the form of its aqueous solution, the concentration is 2mmol / L) and 20mg sodium dodecylbenzenesulfonate (added in the form of its aqueous solution, the concentration is 0.1mg / mL), stir well, add NaOH to adjust the pH of the solution to 10. The above solution was transferred to a test tube and filled with nitrogen gas for 30 minutes, and sealed with 60 Coγ-rays were irra...

Embodiment 2

[0051] Example 2. Preparation of electromagnetic shielding-polymer nanocomposites under different solvent conditions

[0052] 1) Preparation of metal nanoparticles / graphene / carbon nanotubes three-dimensional network structure electromagnetic shielding materials

[0053] The method of step 1) in Example 1 is basically the same, except that the solvent is replaced by ethanol, ethylene glycol, water, tetrahydrofuran or N-methylpyrrolidone in sequence.

[0054] 2) Preparation of electromagnetic shielding-polymer nanocomposites

[0055] Same as the method of 2) step in Example 1.

[0056] The electromagnetic shielding effectiveness of the sample prepared in this embodiment was tested by an electromagnetic shielding test system, and the results are as follows:

[0057] When ethanol is used as the solvent, the electromagnetic shielding effectiveness of the sample prepared under the condition of 8-12GHz is 24.3dB;

[0058] When ethylene glycol is used as the solvent, the electromag...

Embodiment 3

[0062] Example 3. Preparation of electromagnetic shielding-polymer nanocomposites under different metal salt conditions

[0063] 1) Preparation of metal nanoparticles / graphene / carbon nanotubes three-dimensional network structure electromagnetic shielding materials

[0064] With embodiment 1 in 1) the method of step is basically the same, difference is: metal salt is replaced successively by ferric chloride, ferric nitrate, cobalt chloride, nickel acetate, nickel chloride, nickel nitrate, nickel sulfate, gold chloride acid, sodium chloroaurate, silver nitrate, or chloroplatinic acid.

[0065] 2) Preparation of electromagnetic shielding-polymer nanocomposites

[0066] Same as the method of 2) step in Example 1.

[0067] The electromagnetic shielding effectiveness of the sample prepared in this embodiment was tested by an electromagnetic shielding test system, and the results are as follows:

[0068] When the metal salt is iron salt, the electromagnetic shielding effectiveness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com