Process for producing N-acetylglucosamine

A technology of acetylamino and glucose, applied in the biological field, can solve the problems of high environmental pollution, low reaction efficiency, difficult process control, etc., and achieve the effect of reducing production costs, reducing safety hazards, and simple product separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

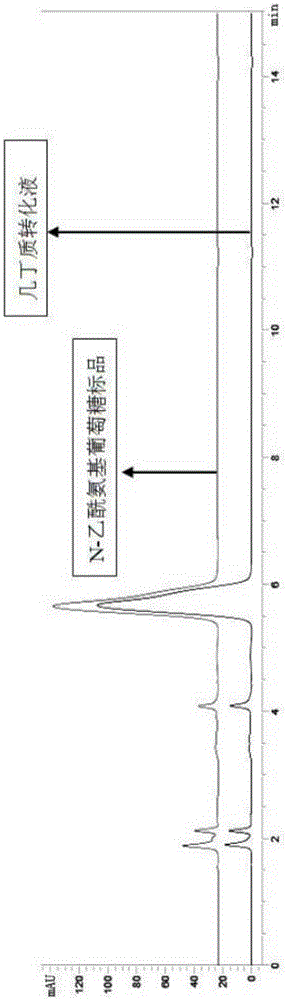

Image

Examples

Embodiment 1

[0028] Step 1, preparation of chitin crude enzyme solution

[0029] Pick Chitinolytic bacterium meiyuanensis SYBC-H1 in the culture medium (2g / L glucose, 2g / L peptone, 0.7g / LKH 2 PO 4 , 0.3g / LK 2 HPO 4 ·3H 2 O, 0.4g / LMgSO 4 ·7H 2 O, pH7.0) 37°C, 200rpm for 12h to obtain the seed solution, according to the volume fraction of 5% inoculum into a 7.5L fermenter equipped with a liquid enzyme-producing fermentation medium, the liquid volume is 3L, and the enzyme-producing fermentation medium is (5g / L chitin powder, 5g / L Jerusalem artichoke powder, 5g / L peptone, 5g / L beef extract, 0.7g / LKH 2 PO 4 , 0.3g / LK 2 HPO 4 ·3H 2 O, 0.5g / LMgSO 4 ·7H 2 O) The culture temperature is 26°C, the rotation speed is 250rpm, the ventilation rate is 1vvm, the initial pH is 7.0, and the fermentation liquid is collected after 80 hours of fermentation. The fermentation broth was centrifuged at 7000g to separate the bacteria, and the supernatant, namely the crude chitinase enzyme solution, wa...

Embodiment 2

[0037] Step 1, preparation of chitin crude enzyme solution

[0038] preparation Chitinolytic bacterium meiyuanensis SYBC-H1 seed solution, medium (2g / L glucose, 2g / L peptone, 0.7g / LKH 2 PO 4 , 0.3g / LK 2 HPO 4 ·3H 2 O, 0.4g / LMgSO 4 ·7H 2 O, pH7.0), cultured at 37°C and 200rpm for 12 hours, the seeds were inserted into a 7.5L fermenter with a liquid enzyme-producing fermentation medium with a volume fraction of 7% inoculum, and the liquid volume was 3L, and the enzyme-producing medium was ( 5g / L chitin powder, 5g / L Jerusalem artichoke powder, 5g / L yeast extract, 5g / L peptone, 0.7g / LKH 2 PO 4 , 0.3g / LK 2 HPO 4 ·3H 2 O, 0.5g / LMgSO 4 ·7H 2 O) The culture temperature is 26°C, the rotation speed is 300rpm, the ventilation rate is 1vvm, the initial pH is 7.0, and the fermentation broth is collected after 80 hours of fermentation. The fermentation broth was centrifuged at 8000 g to separate the bacteria, and the supernatant, namely the crude chitinase enzyme solution, wa...

Embodiment 3

[0046] Influence of temperature on adsorption effect in step 2.

[0047] The supernatant of the fermented liquid collected in centrifugation embodiment 1, in the process of step 2 adsorption enzyme, by changing temperature, other conditions are consistent, along with the rising of temperature, adsorption capacity increases, but along with raising further, adsorption The effect becomes smaller instead. The final study showed that the optimum temperature was 20°C (see attached table 2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com