Basalt fiber enhanced environment-friendly flame-retardant ABS composite material and preparation method thereof

A technology of basalt fiber and composite materials, which is applied in the field of high-strength basalt fiber-reinforced flame-retardant and environmentally friendly ABS composite materials and its preparation, can solve the problems of not fully satisfying the use performance, expensive carbon fiber, and limited application fields, etc., to achieve good strength, Improved surface quality and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

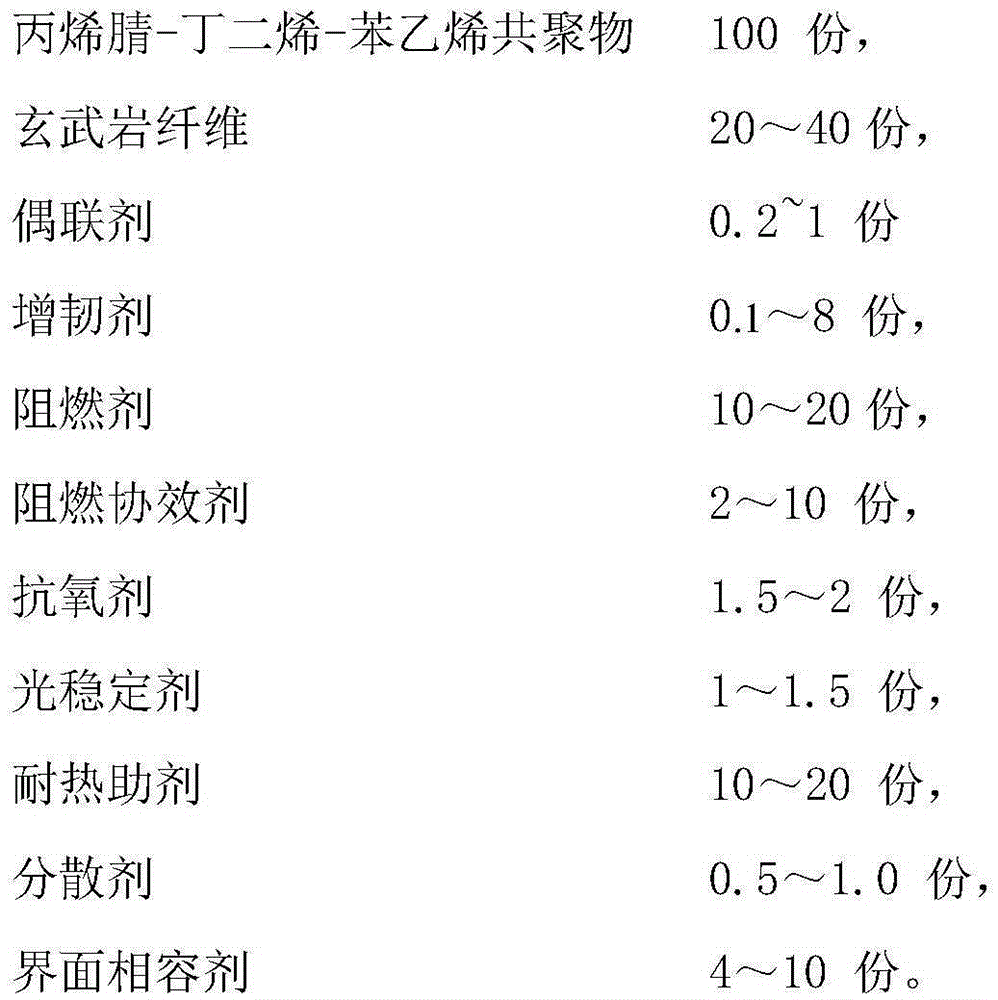

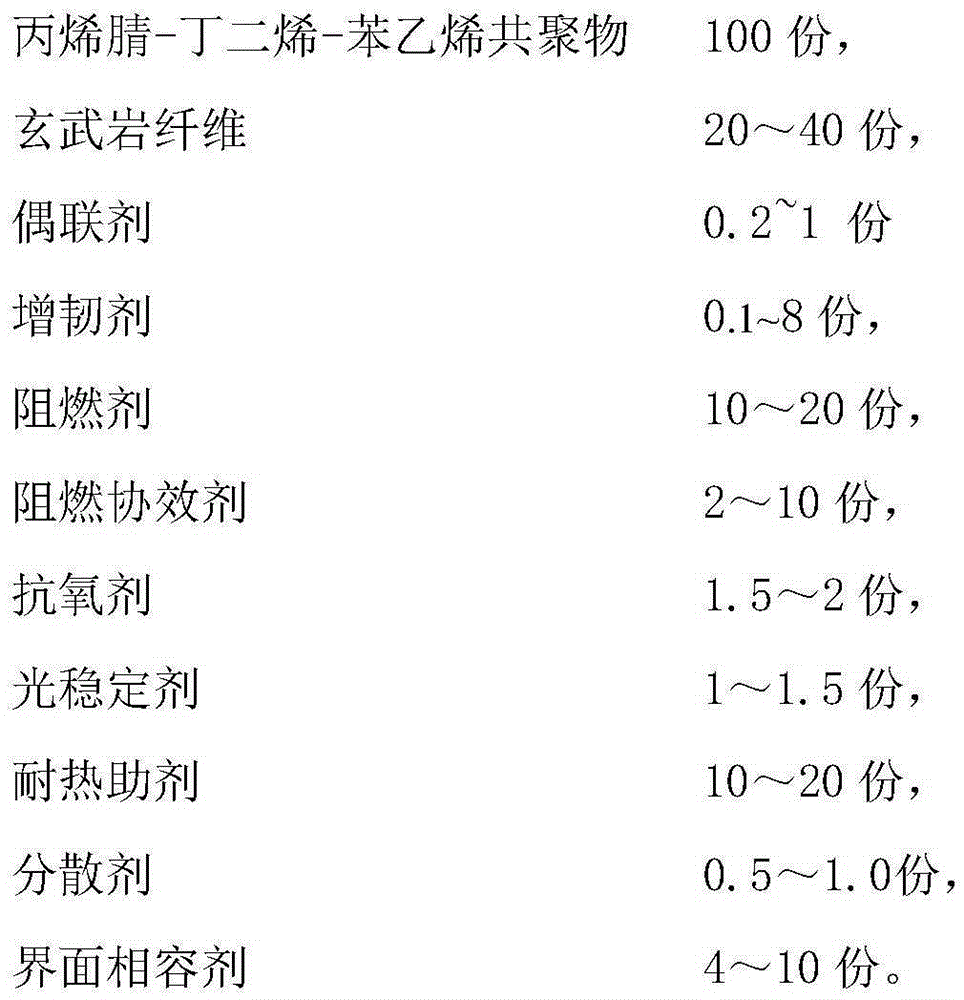

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of an environmentally friendly flame-retardant ABS composite material reinforced by basalt fibers, comprising the following steps:

[0034] According to the proportion of the formula, 100 parts of ABS (acrylonitrile-butadiene-styrene copolymer), 35 parts of basalt fiber (treated by N-β-aminoethyl-γ-aminopropyltrimethoxysilane), ethylene acrylic acid methyl 5 parts of ester carbonyl copolymer, 12 parts of melamine cyanurate, 3 parts of zinc borate, 1.5 parts of [β-(3,5 di-tert-butyl 4-hydroxy-phenyl)propionic acid] pentaerythritol ester, tri(phosphite Add 12 parts of 1,2,2,6,6-pentamethylpiperidine) ester, 15 parts of polymethacrylimide, 5 parts of epoxy resin, and 0.8 part of zinc stearate into a high-speed mixer at a speed of 1000r / min, after mixing for 2 minutes, discharge;

[0035] Put the mixed material in a twin-screw extruder to melt, mix, extrude and granulate. The segmental temperature of the screw extruder is 180-190°C, 195-205°C, 210-220°...

Embodiment 2

[0038] A preparation method of an environmentally friendly flame-retardant ABS composite material reinforced by basalt fibers, comprising the following steps:

[0039]According to the proportion of the formula, 100 parts of ABS (acrylonitrile-butadiene-styrene copolymer), 32 parts of basalt fiber (treated by γ-(methacryloyloxy)propyltrimethoxysilane), ethylene-vinyl acetate copolymer 3 parts of melamine phosphate, 10 parts of melamine phosphate, 4 parts of antimony trioxide, 1.8 parts of N, N'-di(β-naphthyl)-p-phenylenediamine, 1.0 parts of 2-hydroxy-4-methoxybenzophenone 12 parts of polymethacrylimide, 5 parts of styrene-grafted maleic anhydride, and 0.5 parts of N, N'-ethylenebisstearic acid amine were added to a high-speed mixer at a speed of 920r / min, and mixed Discharge after 3min;

[0040] Put the mixed material in a twin-screw extruder to melt, mix, extrude and granulate. The segmental temperature of the screw extruder is 180-190°C, 195-205°C, 210-220°C, 200-210°C, and...

Embodiment 3

[0043] A preparation method of an environmentally friendly flame-retardant ABS composite material reinforced by basalt fibers, comprising the following steps:

[0044] According to the proportion of the formula, 100 parts of ABS (acrylonitrile-butadiene-styrene copolymer), 40 parts of basalt fiber (treated by N-β-aminoethyl-γ-aminopropyltrimethoxysilane), polyamide resin 4 parts, 20 parts of melamine borate, 6 parts of antimony trioxide, 1.5 parts of [β-(3,5 di-tert-butyl 4-hydroxy-phenyl)propionic acid] pentaerythritol ester, 2-hydroxy-4-methanol Add 1.5 parts of oxybenzophenone, 10 parts of N-phenyl grafted maleimide, 2 parts of epoxy resin, 2 parts of styrene grafted maleic anhydride, and 1.0 parts of lithium stearate into the high-speed mixer , the rotating speed is 800r / min, and the material is discharged after mixing for 4 minutes;

[0045] Put the mixed material in a twin-screw extruder to melt, mix, extrude and granulate. The segmental temperature of the screw extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap