High-adhesion polyaniline anticorrosive coating and preparation method thereof

An anti-corrosion coating and high-adhesion technology, used in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor mechanical processing performance resin compatibility, limited use of polyaniline, weak bonding strength, etc. Good overall performance, low production cost, good salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

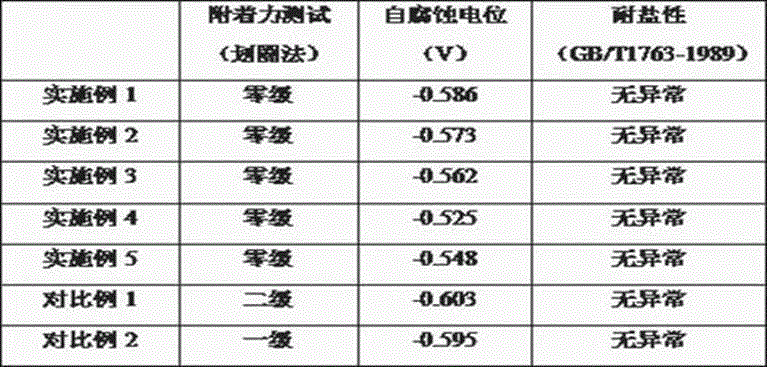

Examples

Embodiment 1

[0020] A kind of high adhesion polyaniline anticorrosion coating, described anticorrosion coating comprises following composition, counts as in parts by weight: 42 parts of acrylic resins, 16 parts of cyanate resins, 12 parts of polyurethane acrylates, 6 parts of polyaniline powders, 5 parts of brucite powder, 3 parts of camphorsulfonic acid, 3 parts of glyceryl tristearate, 4 parts of sodium cocoyl isethionate, 2 parts of zinc oleate, 1 part of citric acid, maleic anhydride grafted polymer 1 part of propylene, 2 parts of titanium dioxide, 1 part of fibrous wollastonite powder, 3 parts of coupling agent, 36 parts of organic solvent, 3 parts of deionized water.

[0021] Preferably, the coupling agent is A171. The organic solvent is a composite of ethyl acetate and isobutanol in a mass ratio of 3:5.

[0022] A kind of preparation method of above-mentioned high adhesion polyaniline anticorrosion coating, described method comprises the steps:

[0023] (1) Add citric acid, organi...

Embodiment 2

[0028] A kind of high adhesion polyaniline anticorrosion coating, described anticorrosion coating comprises following composition, counts as in parts by weight: 60 parts of acrylic resins, 27 parts of cyanate resins, 20 parts of polyurethane acrylates, 13 parts of polyaniline powders, 11 parts of brucite powder, 9 parts of camphorsulfonic acid, 10 parts of glyceryl tristearate, 8 parts of sodium cocoyl isethionate, 7 parts of zinc oleate, 6 parts of citric acid, maleic anhydride grafted polymer 5 parts of propylene, 5 parts of titanium dioxide, 3 parts of fibrous wollastonite powder, 9 parts of coupling agent, 55 parts of organic solvent, and 9 parts of deionized water.

[0029] Preferably, the coupling agent is KH550. The organic solvent is a composite of isobutanol and cyclohexanone in a weight ratio of 2:7.

[0030] A kind of preparation method of above-mentioned high adhesion polyaniline anticorrosion coating, described method comprises the steps:

[0031] (1) Add citric...

Embodiment 3

[0036] A kind of high adhesion polyaniline anticorrosion coating, described anticorrosion coating comprises following composition, counts as in parts by weight: 51 parts of acrylic resins, 22 parts of cyanate resins, 16 parts of polyurethane acrylates, 10 parts of polyaniline powders, 8 parts of brucite powder, 6 parts of camphorsulfonic acid, 6 parts of glyceryl tristearate, 7 parts of sodium cocoyl isethionate, 5 parts of zinc oleate, 3 parts of citric acid, maleic anhydride grafted polymer 3 parts of propylene, 3 parts of titanium dioxide, 2 parts of fibrous wollastonite powder, 6 parts of coupling agent, 45 parts of organic solvent, 6 parts of deionized water.

[0037] Preferably, the coupling agent is KH550. The organic solvent is a composite of ethyl acetate, isobutanol and cyclohexanone in a weight ratio of 3:1:5.

[0038] A kind of preparation method of above-mentioned high adhesion polyaniline anticorrosion coating, described method comprises the steps:

[0039] (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com