Covering device for high-titanium slag smelting furnace

A smelting furnace and high-titanium slag technology, which is applied in the field of capping devices for high-titanium slag smelting furnaces, can solve problems such as the entry of toxic gases and dust, small production scale of titanium slag, and unstable smelting operations, etc., to save maintenance costs and improve Working environment, the effect of avoiding oxidation and burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

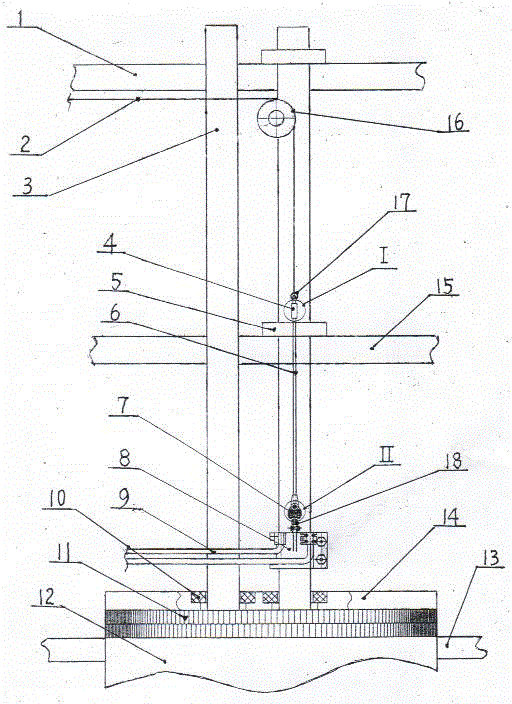

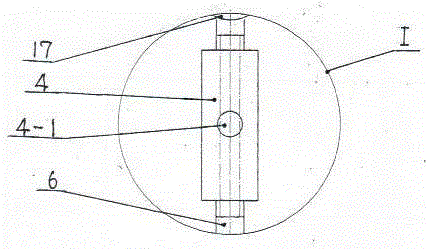

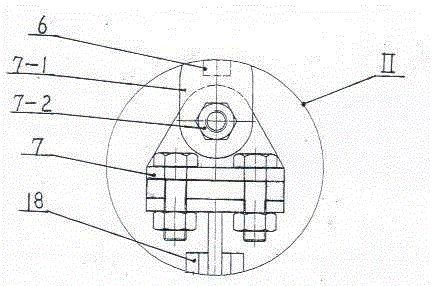

[0012] Examples, see attached Figure 1~4 , the high titanium slag smelting furnace cover device is provided with a high alumina insulator 11 above the furnace body 12, and a metal water-cooled furnace cover 14 is connected above the high alumina insulator 11. The metal water-cooled furnace cover 14 adopts Q245 boiler plate, and the sub-arc Bottom arc welding and over-surface welding are formed, and a circulating water channel 14-2 is provided in the metal water-cooled furnace cover 14, and the circulating water channel 14-2 connects two water inlets 14-4 and two water outlets 14-3. Three graphite electrode holes are arranged at an angle of 120 degrees on the metal water-cooled furnace cover 14, and a refractory insulating ring 10 is arranged on the edge of the graphite electrode holes, and a plurality of feeding observation holes 14-1 are arranged on the metal water-cooled furnace cover 14. An electrode holder 8 is installed on each graphite electrode 3 above the metal water-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com