Preparation method of light absorption layer of CIGS-base thin film solar cell

A technology for solar cells and light-absorbing layers, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as uneven composition of light-absorbing layers, achieve the effect of reducing the number of surface defects and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

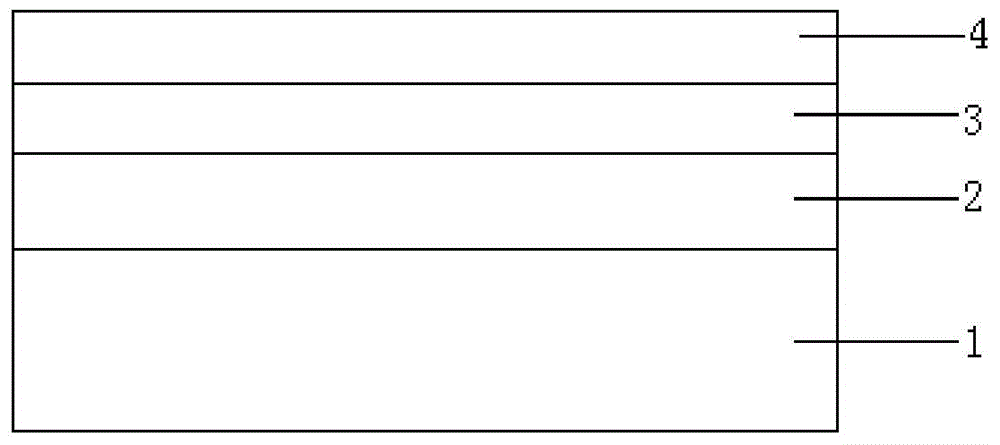

[0049] Deposit a molybdenum electrode layer on the soda-lime glass substrate, then deposit a copper-gallium alloy film layer on the molybdenum electrode layer, then deposit a layer of indium layer on the copper-gallium alloy film layer, and then send the substrate into the heating furnace , using a vacuum pump to take out the gas in the heating furnace to maintain the pressure in the heating furnace at 10 -5 Torr;

[0050] Raise the temperature in the heating furnace from room temperature to 150°C and maintain it at 150°C for 60 minutes;

[0051] After that, the gas containing hydrogen selenide is passed into the heating furnace while maintaining the pressure in the furnace at 600 Torr, and the temperature in the heating furnace is raised from 150°C to 350°C, and maintained at 350°C for 120min;

[0052] After that, remove the residual selenium-containing substance gas in the heating furnace, and then feed nitrogen to maintain the pressure in the furnace at 600 Torr, and incre...

Embodiment 2

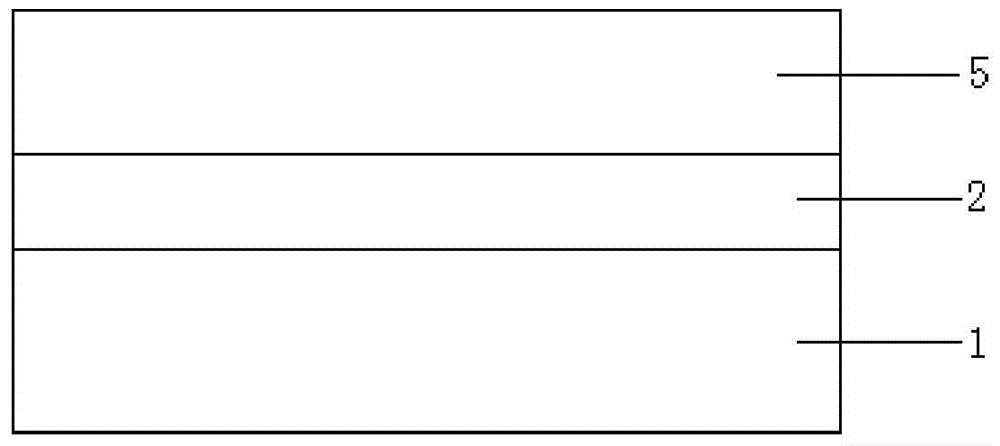

[0057] Deposit a molybdenum electrode layer on the soda-lime glass substrate, then deposit a copper-gallium alloy film layer on the molybdenum electrode layer, then deposit a layer of indium layer on the copper-gallium alloy film layer, and then send the substrate into the heating furnace , using a vacuum pump to take out the gas in the heating furnace to maintain the pressure in the heating furnace at 10 -5 Torr;

[0058] Raise the temperature in the heating furnace from room temperature to 250°C and maintain it at 250°C for 30s;

[0059] Afterwards, the gas containing hydrogen selenide is passed into the heating furnace while maintaining the pressure in the furnace at 600 Torr, and the temperature in the heating furnace is raised from 250°C to 450°C, and maintained at 450°C for 5 minutes;

[0060] Afterwards, the residual selenium-containing substance gas in the heating furnace is removed, and then nitrogen gas is introduced to maintain the pressure in the furnace at 600 To...

Embodiment 3

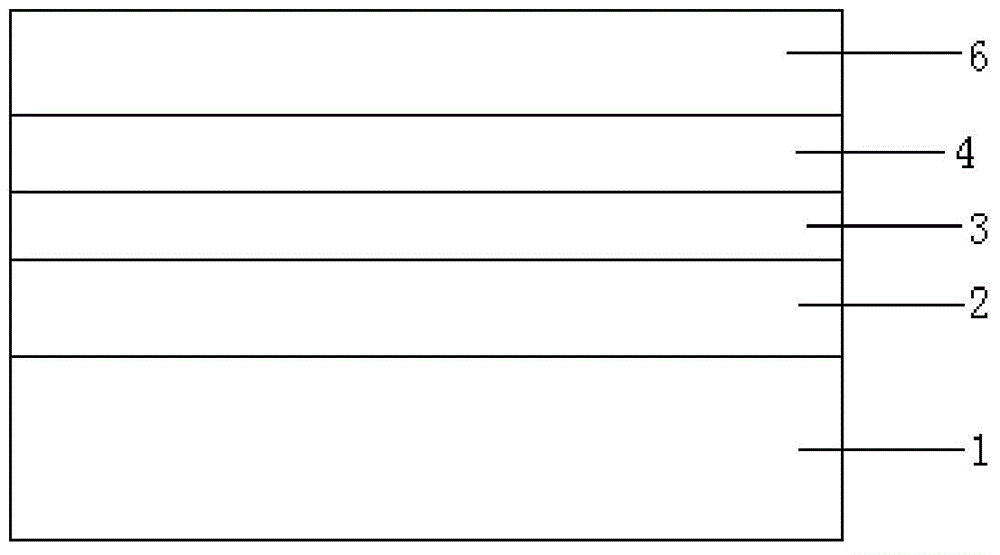

[0065] Deposit a molybdenum electrode layer on the soda-lime glass substrate, then deposit a copper-gallium alloy film layer on the molybdenum electrode layer, then deposit a layer of indium layer on the copper-gallium alloy film layer, and then send the substrate into the heating furnace , using a vacuum pump to take out the gas in the heating furnace to maintain the pressure in the heating furnace at 10 -5 Torr;

[0066] Raise the temperature in the heating furnace from room temperature to 160°C and maintain it at 160°C for 30 minutes;

[0067] After that, the gas containing hydrogen selenide is passed into the heating furnace while maintaining the pressure in the furnace at 400 Torr, and the temperature in the heating furnace is raised from 160°C to 380°C, and maintained at 380°C for 45min;

[0068] After that, remove the residual selenium-containing substance gas in the heating furnace, and then feed nitrogen to maintain the pressure in the furnace at 400 Torr, and increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com