Method for preparing spherical carbon-coated lithium iron phosphate positive electrode material through atomization method

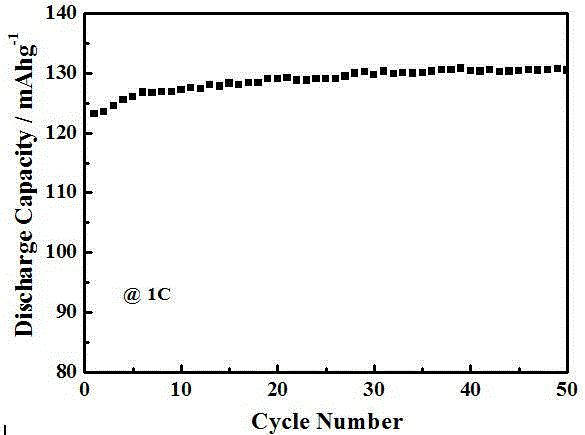

A carbon-coated lithium iron phosphate and cathode material technology, which is applied to battery electrodes, electrochemical generators, electrical components, etc., can solve the agglomeration of lithium iron phosphate materials, uneven particle size distribution, and deterioration of the electrochemical performance of lithium iron phosphate, etc. problems, to achieve the effects of improving high-current charge-discharge performance and cycle performance, reducing production costs, and simplifying the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

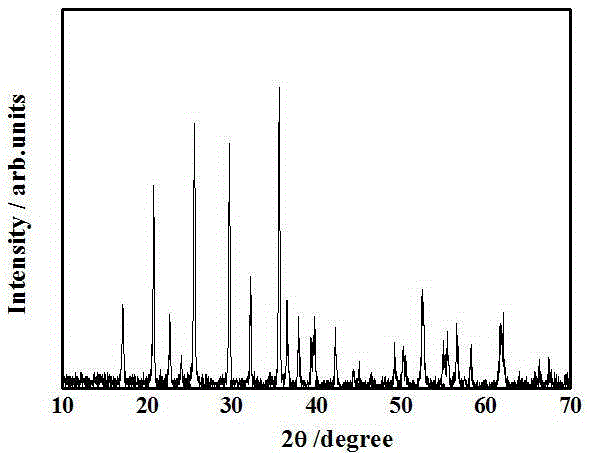

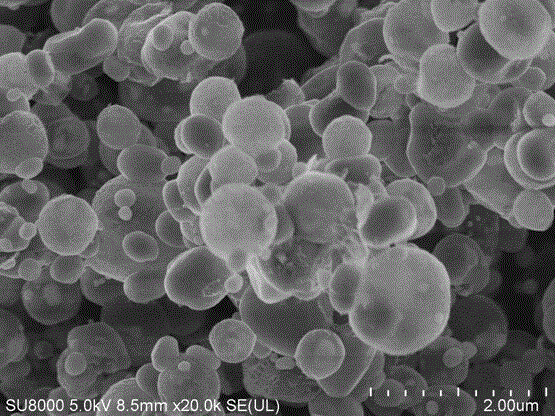

[0038] Dissolve 8.40 grams of citric acid in 400 milliliters of deionized water, stir magnetically for 1 hour at room temperature, weigh 16.16 grams of ferric nitrate trihydrate, 2.84 grams of lithium nitrate, 1.10 grams of sucrose, and 4.74 grams of ammonium dihydrogen phosphate to the mixture , adding concentrated ammonia water dropwise to adjust the pH value of the solution and stirring continuously, the final pH value of the solution is about 6.5. Put the mixed solution after adjusting the PH value in an 80°C water bath for 3 hours and then put it into an ultrasonic atomization device, set the atomization volume to 0.4 ml per minute, and turn on the piezoelectric ceramic chip with a frequency of 1.7MHz. The atomized liquid droplets produced are loaded into the tube furnace (the inner diameter of the quartz tube of the tube furnace is 20mm and the outer diameter is 25mm) at a temperature of 550°C by the vacuum pump, and the atomized liquid droplets are placed in the quartz t...

Embodiment 2

[0042] Dissolve 8.20 g of citric acid in 300 ml of deionized water, stir magnetically at room temperature for 30 minutes, weigh 4.15 g of lithium dihydrogen phosphate, 10.81 g of ferric chloride hexahydrate, and 1.20 g of glucose into the mixture, and add Ethylenediamine adjusts the pH value of the solution and keeps stirring, and the final pH value of the solution is about 7. Put the mixed solution after adjusting the pH value in a water bath at 70°C for 1 hour, then put it into an ultrasonic atomization device, set the atomization volume to 0.6 ml per minute, and turn on the piezoelectric ceramic chip with a frequency of 2.4 MHz. The atomized liquid droplets produced are loaded into a tube furnace (the inner diameter of the quartz tube of the tube furnace is 50 mm and the outer diameter is 60 mm) at a temperature of 500 ° C by a vacuum pump, and the atomized liquid droplets are placed in the quartz tube The forward speed is 3cm / s, and the precursor powder generated after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com