Hot-working white mushroom color protection agent and applications thereof

A white mushroom, thermal processing technology, applied in the fields of application, food ingredient function, food science, etc., can solve the problems of unfavorable human health, residue, and destruction of vitamin B, and achieve good color protection effect, low browning degree, and formula scientific effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

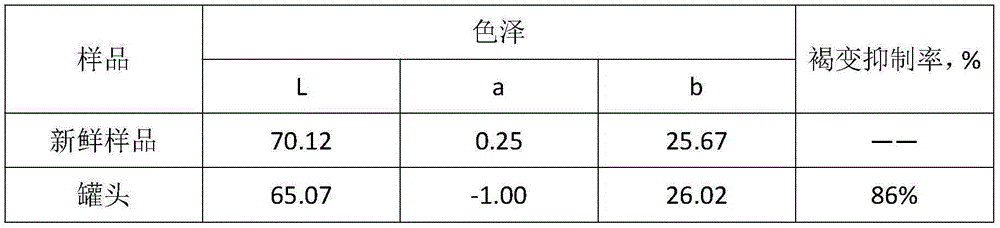

[0023] Example 1 Application of color retention agent of the present invention in canned white mushrooms

[0024] After the fresh white mushrooms are harvested, the mud root stalks are cut off, washed and sliced, and immediately immersed in the color protection liquid for color protection. The color protection liquid formula is 3% calcium ascorbate, 0.5% calcium propionate, 0.8% sodium chloride , 0.1% L-cysteine, 0.02% disodium edetate, color protection conditions: immersion treatment at 20℃ for 15min, solid-liquid ratio 1:8, then blanching at 100℃ for 1 minute, cooling and draining Dried, weighed, canned and added soup, sterilized and cooled (10'-30'-10' / 121°C, that is, the temperature will be raised to 121°C in 10 minutes, kept for 30 minutes, and cooled in 10 minutes), and placed in a 37°C incubator After 3 days, the browning inhibition rate (R) and color (L, a and b values) of the samples were measured. The results are shown in Table 1 (fresh samples are newly harvested white...

Embodiment 2

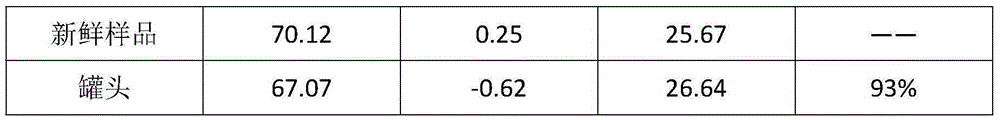

[0027] Example 2 Application of color retention agent of the present invention in canned white mushrooms

[0028] After the fresh white mushrooms are harvested, cut off the root stalks with mud, cleaned and sliced and immediately immersed in the color protection solution for color protection. The color protection solution formula is 4% calcium ascorbate, 1.5% calcium propionate, 1.2% sodium chloride , 0.2% L-cysteine, 0.02% disodium edetate, color protection conditions: 25 ℃ soaking treatment for 25 minutes, solid-liquid ratio 1:12, then 100 ℃ blanching for 1 minute, cooling and draining, Weigh, add soup in cans, sterilize and cool (10'-30'-10' / 121°C), put it in a 37°C incubator for 3 days, determine the browning inhibition rate (R) and color (L, a and b value), and the results are shown in Table 2.

[0029] Table 2 Color and browning degree of canned white mushrooms

[0030]

[0031]

Embodiment 3

[0032] Example 3 Application of color retention agent of the present invention in white mushroom drying

[0033] After the fresh white mushrooms are harvested, cut off the root stalks with mud, cleaned and sliced and immediately immersed in the color protection solution for color protection. The color protection solution formula is 5% calcium ascorbate, 2% calcium propionate, 1.5% sodium chloride , 0.3% L-cysteine, 0.03% disodium ethylenediaminetetraacetic acid, color protection conditions: immersion treatment at room temperature for 30 minutes, solid-liquid ratio 1:15, then blanching at 100°C for 1 minute, cooling and draining , Dried with hot air at 50°C for 10 hours, cooled the package and placed it in an incubator at 37°C for 3 days to determine the browning inhibition rate (R) and color (L, a and b values) of the sample.

[0034] Table 3 Color and browning degree of dried white mushrooms

[0035]

[0036] Sensory evaluation was performed on the canned white mushrooms obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com