Bio-stimulant and preparation method thereof

A bio-growth-promoting agent, biotin technology, applied in the direction of chemical instruments and methods, biological water/sewage treatment, special compound water treatment, etc., can solve the problem of single nutrient composition, limited microbial absorption, and the dosage of bio-growth-promoting agent Increase and other problems, to achieve the effect of rich nutrients, saving transportation costs, and extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1. A kind of biopromoter and preparation method thereof

[0024] A biogrowth accelerator prepared from the following raw materials:

[0025] ①Starch: 45kg

[0026] ②Hydrolyzed casein: 12kg

[0027] ③ Yeast extract: 10kg

[0028] ④EDTA: 4kg

[0029] ⑤NaCl: 4.5kg

[0030] ⑥Biotin: 2kg

[0031] ⑦Distilled water: 22.5kg

[0032] Add ⑦ into the reaction kettle, respectively add ②, ③, ④, ⑤, ⑥ and stir for 15 minutes, then heat the temperature of the reaction kettle to 70°C, add ① and stir for 30 minutes, raise the temperature of the reaction kettle to 121°C, stir for 20 minutes, put The reaction kettle is cooled to about 40°C, and the prepared growth promoter is put into a bucket for use.

Embodiment 2

[0033] Embodiment 2. A kind of biopromoter and preparation method thereof

[0034] A biogrowth accelerator prepared from the following raw materials:

[0035] ①Starch: 40kg

[0036] ②Hydrolyzed casein: 10kg

[0037] ③ Yeast extract: 8kg

[0038] ④EDTA: 3.5kg

[0039] ⑤NaCl: 4kg

[0040] ⑥Biotin: 1.5kg

[0041] ⑦Distilled water: 33kg

[0042] Add ⑦ into the reaction kettle, respectively add ②, ③, ④, ⑤, ⑥ and stir for 20 minutes, then heat the temperature of the reaction kettle to 60°C, add ① and stir for 60 minutes, raise the temperature of the reaction kettle to 121°C, stir for 30 minutes, put The reaction kettle is cooled to about 45°C, and the prepared growth promoter is put into a bucket for use.

Embodiment 3

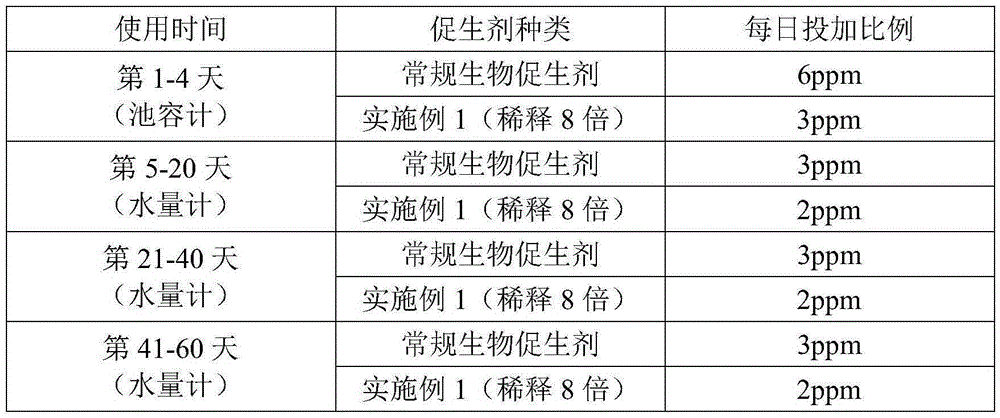

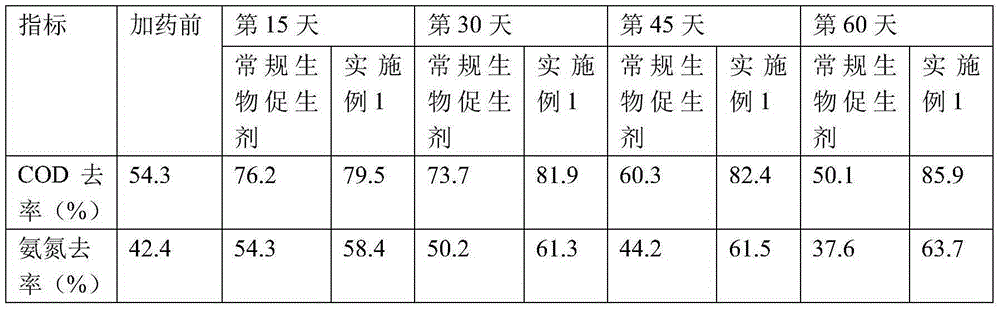

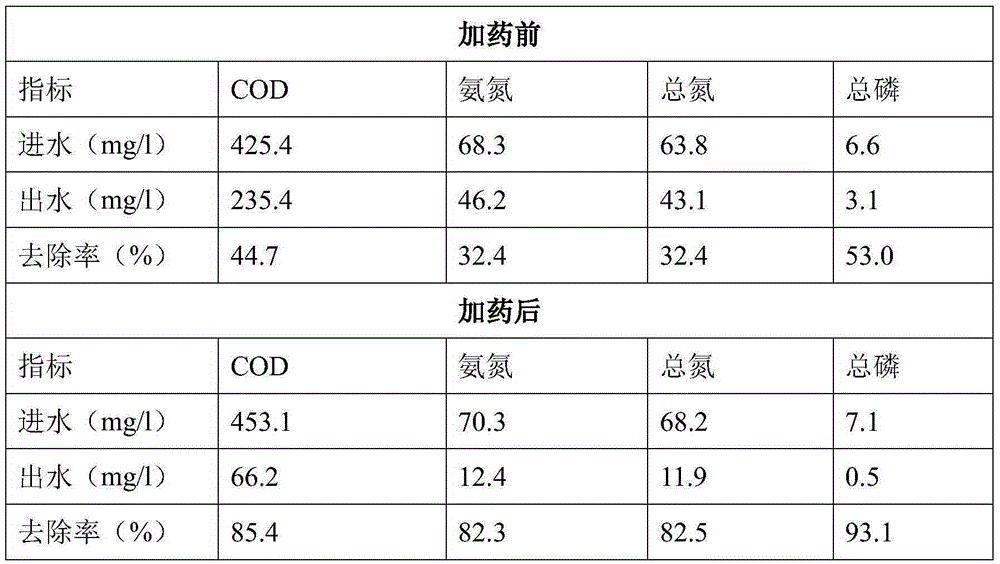

[0043] Embodiment 3, effect experiment

[0044] In a printing and dyeing sewage treatment plant, the average influent COD of the biochemical pool in wastewater: 900mg / L, ammonia nitrogen: 76.52mg / L, the average removal rate of COD in the biochemical system is 78%, and the average removal rate of ammonia nitrogen is 60%. Due to fluctuations in influent water quality, the ability of the printing and dyeing biochemical section to resist fluctuations is weak, so the sewage treatment capacity of the biochemical section is significantly reduced. When using conventional biological growth promoters, the effect is better at the beginning, but after a period of storage in the warehouse, the effect is good. There is obvious weakening, and there is a sour and smelly smell, and some even have long-haired blackening, which seriously affects the hygiene and air of the warehouse. In order to verify the superiority of the antiseptic effect and growth-promoting effect of the present invention, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com