Method for preparation of lithium-doped cubic-phase SnO2 thin film through low-temperature ultrasonic atomization pyrolysis and deposition

An ultrasonic atomization and cubic phase technology is applied in the field of low-temperature ultrasonic atomization and pyrolysis deposition of lithium-doped cubic phase SnO2 thin films, which can solve problems such as affecting the film formation effect, and achieve the effect of improving electrical and optical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] a), substrate selection and cleaning

[0029] Soda-lime glass of 20×20 mm was used as the substrate. The substrate was sonicated with ethanol, acetone and deionized water for 20 minutes, and then dried with nitrogen gas for later use.

[0030] b) Configuration of precursor fluid

[0031] First, a certain mass of stannous chloride solid was weighed and dissolved in 100 mL of absolute ethanol and deionized water with a volume ratio of 3:1 to prepare a 0.1 M / L solution. Secondly, weigh a certain mass of lithium chloride solid and add it to the prepared SnCl 2 2H 2 In O solution, Li + with Sn 2+ The molar ratio is 1:50. The solution was placed on a constant temperature magnetic stirrer and stirred for 0.5 h to obtain a stable and clear precursor solution for future use.

[0032] c), spraying

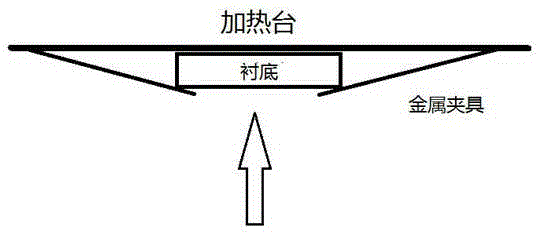

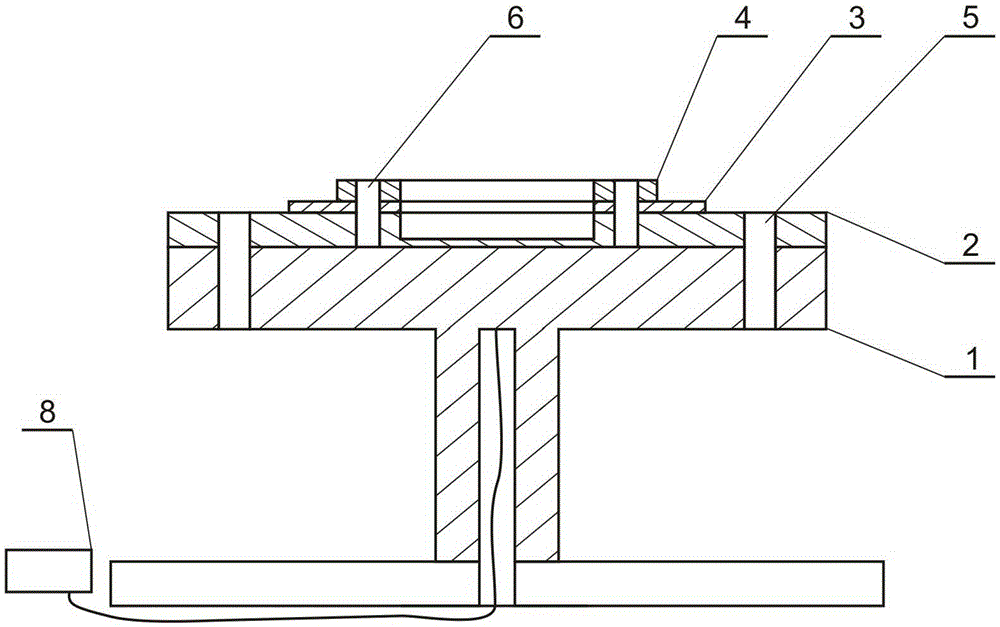

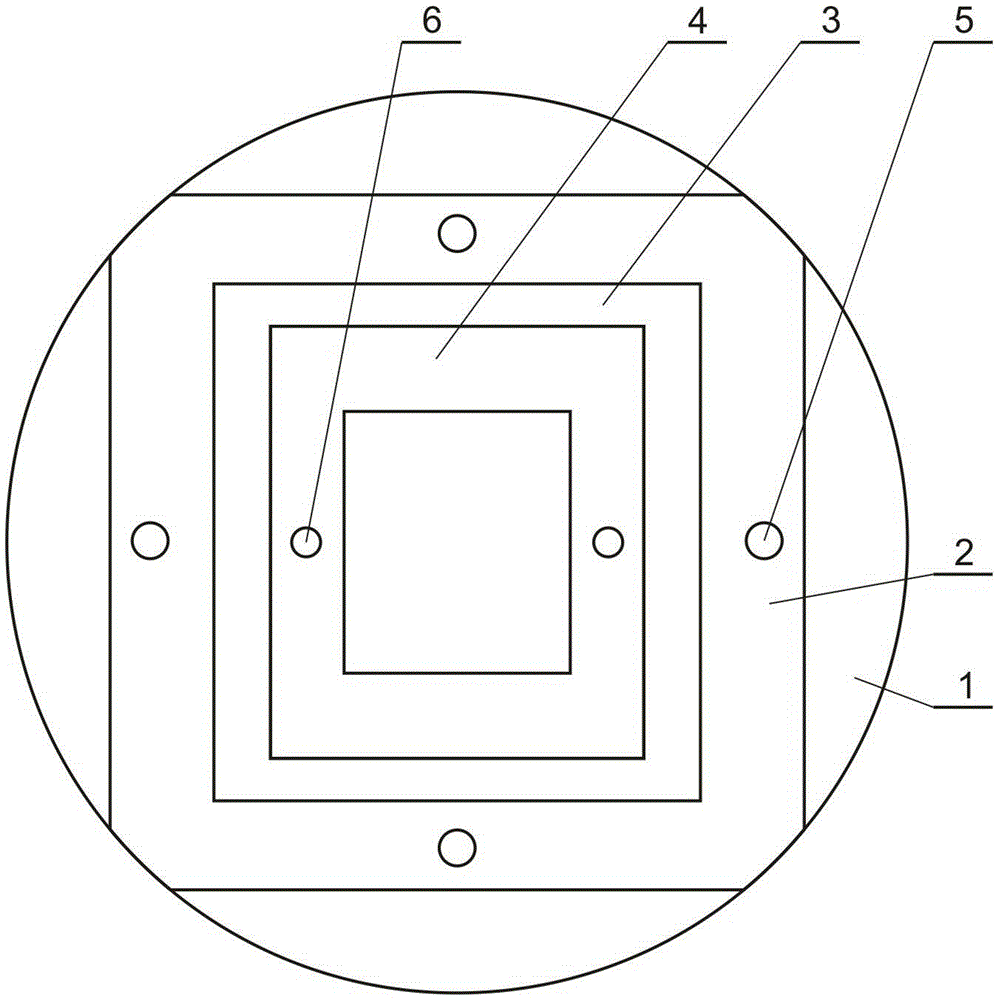

[0033]Set the cleaned substrate in the substrate holder, and use the precursor solution in step b) to carry out ultrasonic atomization and pyrolysis spraying on the substrate....

Embodiment 2

[0035] a) Cleaning of the substrate

[0036] With embodiment 1.

[0037] b) Configuration of precursor fluid

[0038] First, a certain mass of stannous chloride solid was weighed and dissolved in 100 mL of absolute ethanol and deionized water with a volume ratio of 1:1 to prepare a 0.2 M / L solution. Secondly, weigh a certain mass of lithium carbonate solid and add it to the prepared SnCl 2 2H 2 In O solution, Li + with Sn 2+ The molar ratio is 1:50. The prepared solution was placed on a constant temperature magnetic stirrer and stirred for 0.5 h to obtain a stable precursor solution for future use.

[0039] c) Spraying

[0040] Set the cleaned substrate in the substrate holder, and use the precursor solution in step b) to carry out ultrasonic atomization and pyrolysis spraying on the substrate. During the spraying process, the carrier gas is air, and the flow rate is 50mL / min. The distance from the nozzle to the substrate is 1cm, and the substrate temperature is set to...

Embodiment 3

[0042] a) Cleaning of the substrate

[0043] A 20×20 mm glass was used as the substrate. The substrate was sonicated with ethanol, acetone and deionized water for 20 minutes, and then dried with nitrogen gas for later use.

[0044] b) Configuration of precursor fluid

[0045] First, a certain mass of stannous chloride solid was weighed and dissolved in 100 mL of a solvent with a volume ratio of absolute ethanol and deionized water of 1:3 to prepare a 0.05 M / L solution. Secondly, weigh a certain mass of lithium nitrate solid and add it to the prepared SnCl 2 2H 2 In O solution, Li + with Sn 2+ The molar ratio is 1:50. The prepared solution was placed on a constant temperature magnetic stirrer and stirred for 0.5 h to obtain a stable precursor solution for future use.

[0046] c), spraying

[0047] Set the cleaned substrate in the substrate holder, and use the precursor solution in step b) to carry out ultrasonic atomization pyrolytic spraying on the substrate. During th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com