Hydrogel microspheres based on glucan and preparation method thereof

A technology of hydrogel microspheres and gel microspheres, which is applied in the field of biomedical polymer materials, can solve problems such as unproposed reaction conditions and surfactant systems, and achieve good biological safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

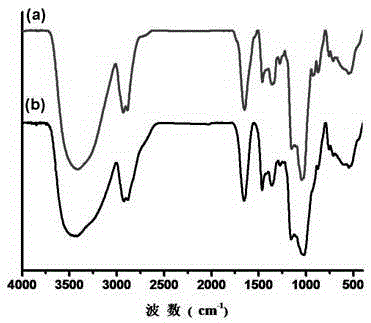

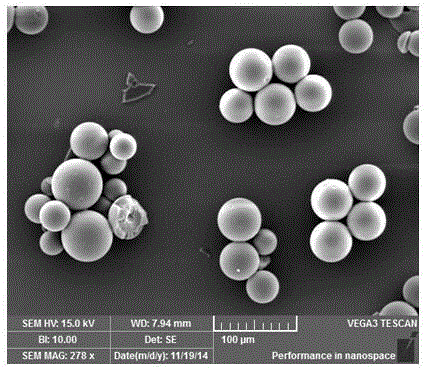

[0034] The structural formula of the dextran-based hydrogel microspheres can be expressed as follows:

[0035] .

[0036] The preparation method of the above-mentioned dextran-based hydrogel microspheres, its specific steps include as follows:

[0037] (1) Preparation of aldylated dextran

[0038] Dissolve 5.0g of dextran (dextran T10, molecular weight 10000g / mol) in water at room temperature according to the solid-to-liquid ratio of 10:100g / ml, and then place it in an ice-water bath according to the sugar unit / IO 4 - Add sodium periodate at a molar ratio of 1:1 to obtain a mixed solution, stir the mixed solution at room temperature and under dark conditions for 4 hours, and dialyze the obtained solution in deionized water for 2 For ~3 days, the deionized water was changed every 3~5h during the dialysis process. After the dialysis was completed, freeze-dried to obtain a partially aldylated dextran solid with a degree of aldylation of 60% (that is, there were 60 sugar unit...

Embodiment 2

[0044] The structural formula of the dextran-based hydrogel microspheres can be expressed as follows:

[0045] .

[0046] The preparation method of the above-mentioned dextran-based hydrogel microspheres, its specific steps include as follows:

[0047] (1) Preparation of aldylated dextran

[0048] Dissolve 5.0g of dextran (dextran T40, molecular weight 40000g / mol) in water at room temperature according to the solid-liquid ratio of 10:100g / ml, and then place it in an ice-water bath according to the sugar unit / IO 4 - Add sodium periodate at a molar ratio of 1:1 to obtain a mixed solution, stir the mixed solution for 4 hours at room temperature and in the dark, and dialyze the obtained solution in deionized water for 2 hours with a regenerated cellulose dialysis bag (molecular weight cut-off: 7kD For ~3 days, the deionized water was changed every 3~5h during the dialysis process. After the dialysis was completed, freeze-dried to obtain a partially aldylated dextran solid wit...

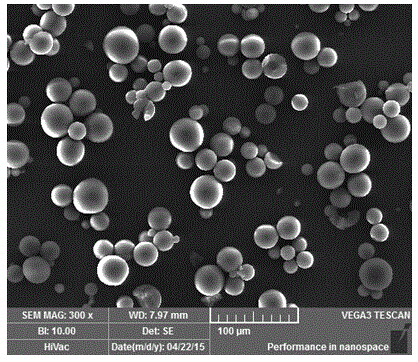

Embodiment 3

[0056] The structural formula of the dextran-based hydrogel microspheres can be expressed as follows:

[0057] .

[0058] The preparation method of the above-mentioned dextran-based hydrogel microspheres, its specific steps include as follows:

[0059] (1) Preparation of aldylated dextran

[0060] Dissolve 5.0g of dextran (dextran T70, molecular weight 70000g / mol) in water at room temperature according to the solid-to-liquid ratio of 10:100g / ml, and then place it in an ice-water bath according to the sugar unit / IO 4 - Add sodium periodate at a molar ratio of 1:1 to obtain a mixed solution, stir the mixed solution for 4 hours at room temperature and in the dark, and dissolve the stirred solution in deionized water with a regenerated cellulose dialysis bag (molecular weight cut-off: 7kD) Dialyze for 2 to 3 days, change the deionized water every 3 to 5 hours during the dialysis process, and freeze-dry after the dialysis to obtain a partially formylated dextran solid with a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com