A method for manufacturing compression-resistant, warpage-resistant, water-repellent, flame-retardant thermal insulation foam material

A flame retardant, thermal insulation and foam material technology, applied in the field of anti-warping, compressive, water-repellent, and flame-retardant thermal insulation foam materials, which can solve the problems of poor mechanical properties of foam plastics, falling of the outer wall surface, and warping of thermal insulation boards. , to achieve the effect of light EPS capacity, low smoke emission and good thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

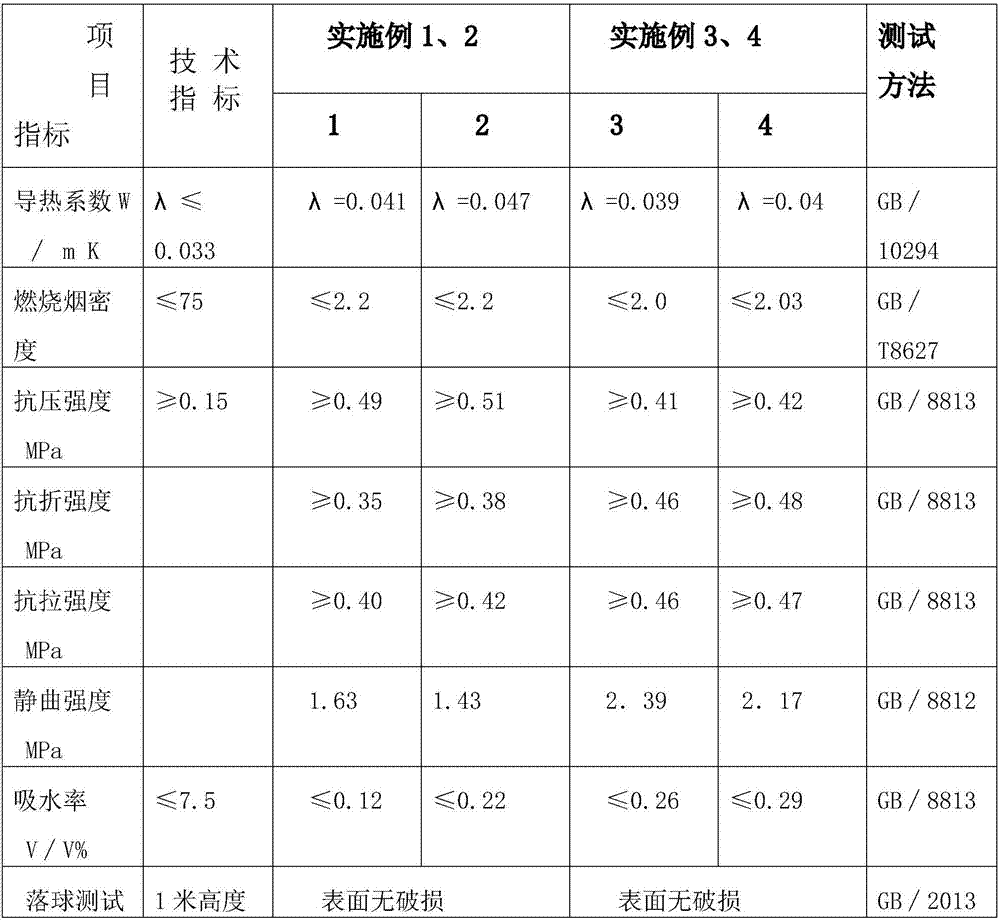

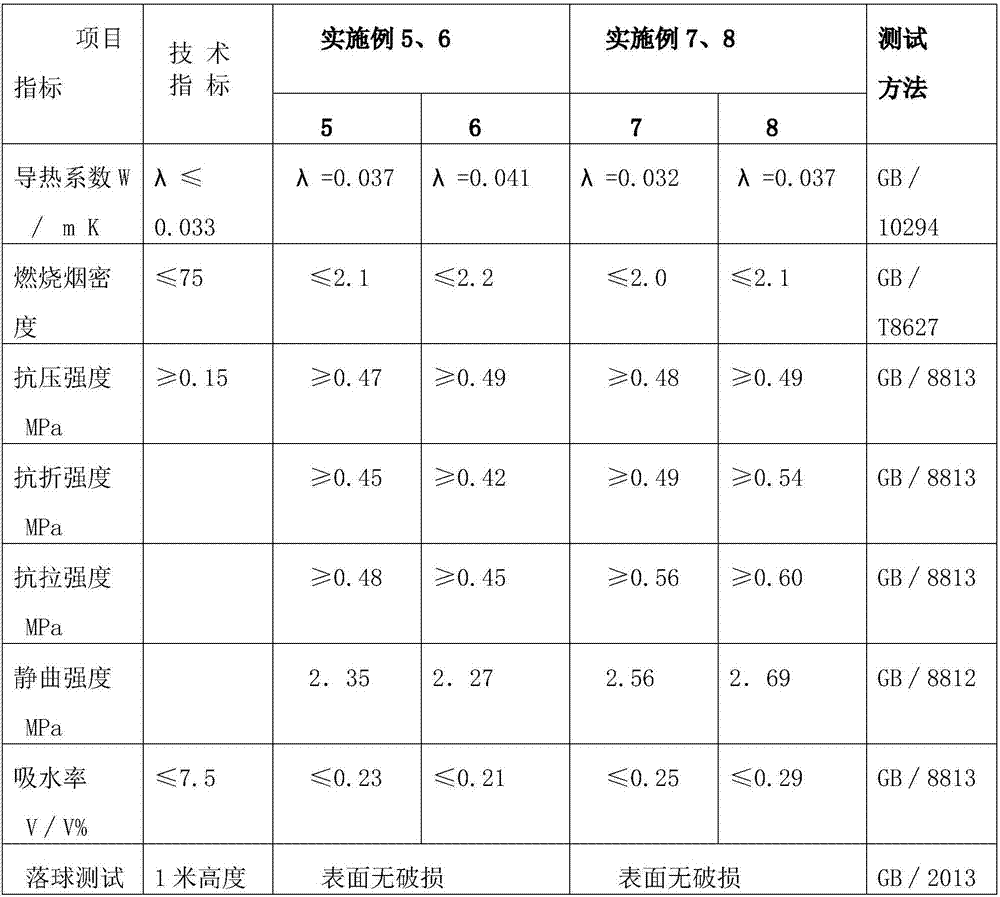

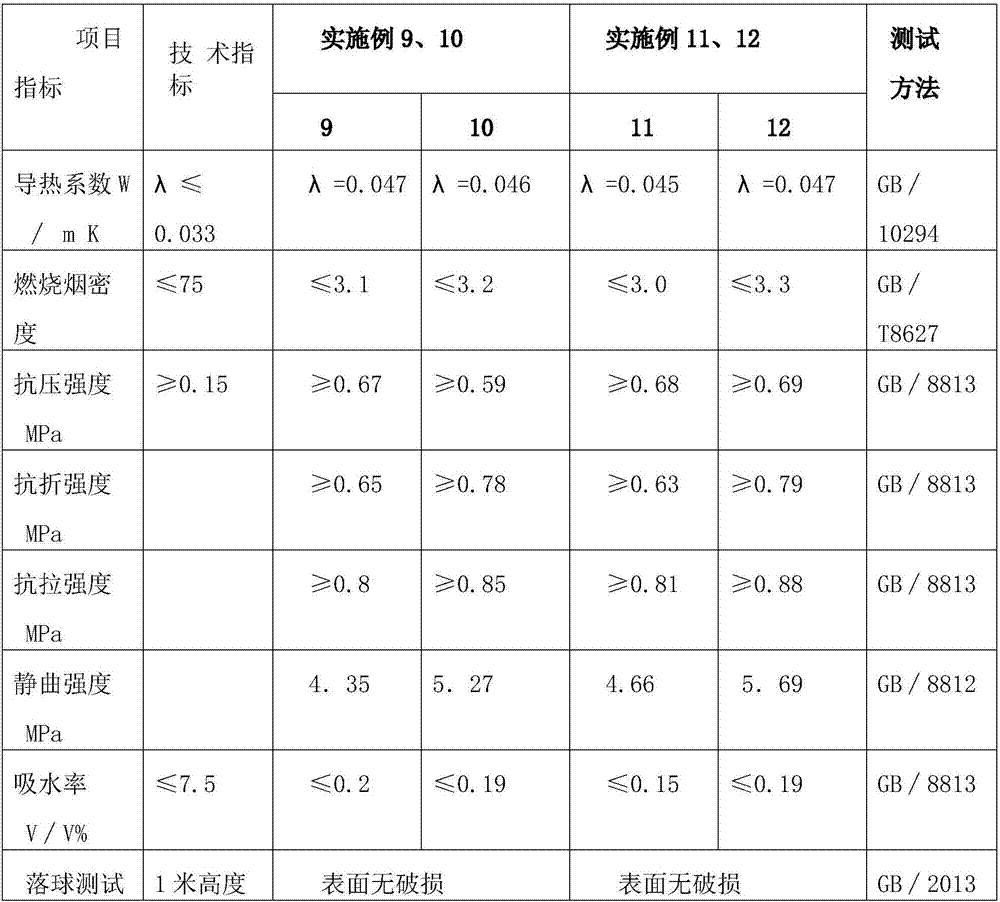

Examples

Embodiment 1

[0037] The phenolic resin with a weight ratio of 64% is the phenolic foaming resin glue; prior uniform blending of silica sol in the phenolic resin accounts for 7% by weight of the phenolic resin, and EPS foam beads account for 5% by weight of the phenolic resin. The glass wool fiber accounts for 15% by weight of the phenolic resin, the glass wool fiber surface treatment agent is 0.5%, the foaming agent is 10% by weight, the surfactant is 2% by weight, the curing agent is 8% by weight, and the toughening agent is The weight ratio is 2%, the weight ratio of the flame retardant is 1%, the weight ratio of the modified filler is 2%, and the weight ratio of the penetrating agent is 3%.

[0038] The phenolic resin is thermosetting phenolic foaming resin glue, the resin solid content is 35-86%, the resin viscosity is 500-8500mpa. 8. The particle size of the silica sol is 25-30nm, SiO 2 The mass fraction is 30%, and the pH value is 9-10. Wherein, EPS foam beads are conventional pol...

Embodiment 2

[0041] The phenolic resin with a weight ratio of 57% is the phenolic foam resin glue; the silica sol uniformly blended in advance in the phenolic resin accounts for 2% by weight of the phenolic resin, and the EPS foam beads account for 5% by weight of the phenolic resin. The glass wool fiber accounts for 25% by weight of the phenolic resin, the glass wool fiber surface treatment agent is 1.5%, the foaming agent is 13% by weight, the surfactant is 4% by weight, the curing agent is 9% by weight, and the flame retardant The weight ratio is 3%, the weight ratio of the modified filler is 8%, and the weight ratio of the penetrating agent is 6%.

[0042] The phenolic resin is thermosetting phenolic foaming resin glue, the resin solid content is 35-86%, the resin viscosity is 500-8500mpa. 8. The particle size of the silica sol is 25-30nm, SiO 2 The mass fraction is 30%, and the pH value is 9-10. Wherein, EPS foam beads are conventional polystyrene beads containing blowing agent. T...

Embodiment 3

[0045] In the mold to be prepared, the phenolic resin with a weight ratio of 64% is the phenolic foam resin glue; the phenolic resin is evenly blended with silica sol in advance, accounting for 8% by weight of the phenolic resin, EPS foam beads account for The weight ratio of phenolic resin is 5%, the weight ratio of mineral wool fiber to phenolic resin is 35%, the surface treatment agent of mineral wool fiber is 0.5%, the weight ratio of foaming agent is 10%, and the weight ratio of surfactant is 2%. The weight ratio of the agent is 9%, the weight ratio of the modifier is 2%, the weight ratio of the flame retardant is 1%, the weight ratio of the modified filler is 2%, and the weight ratio of the penetrating agent is 3%.

[0046] The phenolic resin is thermosetting phenolic foaming resin glue, the resin solid content is 35-86%, the resin viscosity is 500-8500mpa. 8. The particle size of the silica sol is 25-30nm, SiO 2The mass fraction is 30%, and the pH value is 9-10. Wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com