Adhesive for carrying out heat vulcanization adhesion on EPDM (Ethylene-Propylene-Diene Monomer) and metal

A technology of EPDM rubber and vulcanized bonding, which is applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of low tear strength, complicated use process, easy decomposition and deterioration, etc., and achieve Effect of high bond strength, low biological toxicity, and stable storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

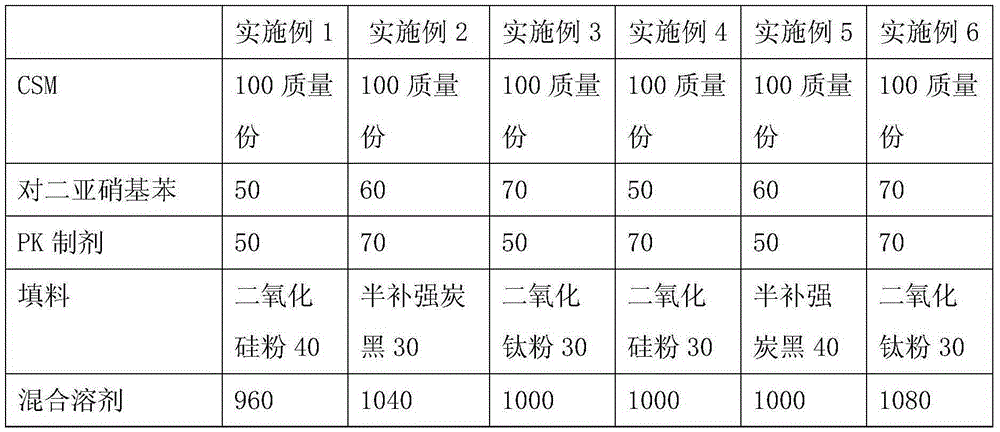

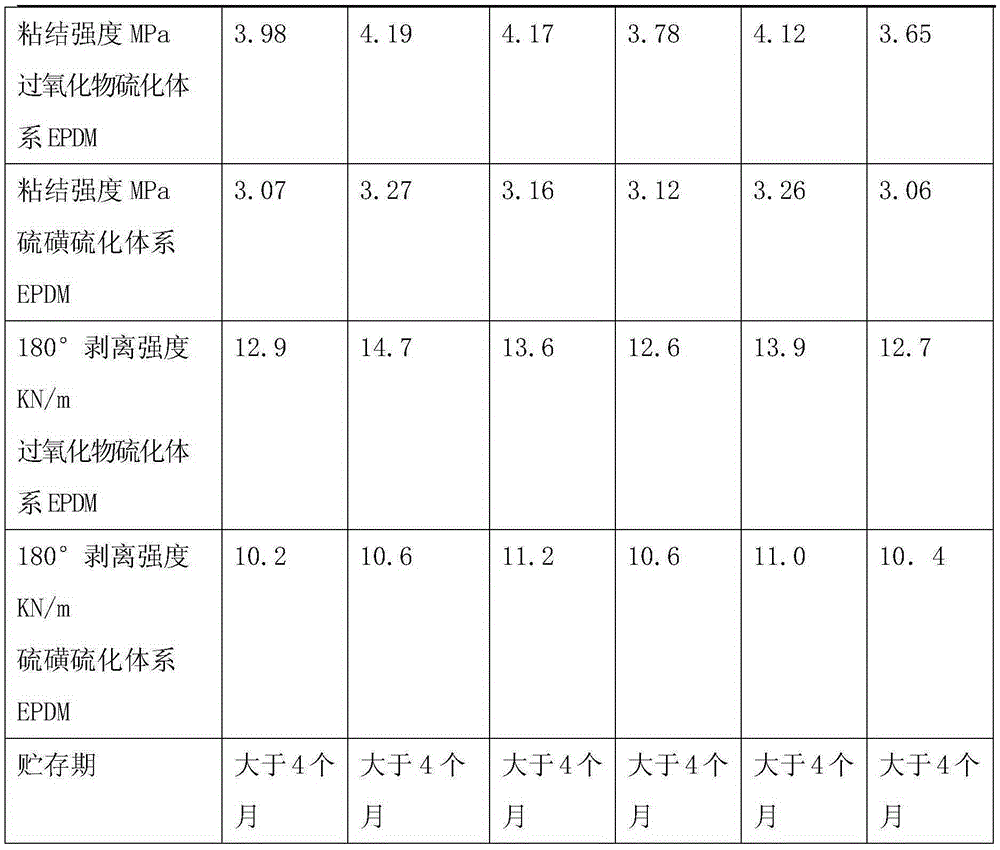

[0015] The content of the present invention will be further specifically described below in conjunction with examples, but the protection scope of the present invention is by no means limited to these examples.

[0016] The synthesis of the PK preparation in Example 1-3 is as follows: first dissolve 100 parts by weight of polyisocyanate PAPI in 30 parts by weight of mixed solvent to prepare A solution, dissolve 50 parts by weight of silane coupling agent KH550 in 30 parts by weight of mixed Solvent to prepare B solution. The solution B was slowly dropped into the solution A under the protection of nitrogen gas, and the temperature was controlled to be lower than 40°C. After the addition was completed, the reaction was carried out under the protection of nitrogen gas for 2 hours. Wherein the mixed solvent is a blended solvent of tetrachloroethylene and xylene, and the mass ratio of tetrachloroethylene to xylene is 1:1.

[0017] The synthesis of the PK preparation in embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com