Preparation method of lead-free piezoelectric thin film

A lead-free piezoelectric and thin-film technology, applied in solid-state chemical plating, metal material coating process, coating and other directions, can solve the problems of lead-containing films, and achieve the effect of simple equipment, low cost and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

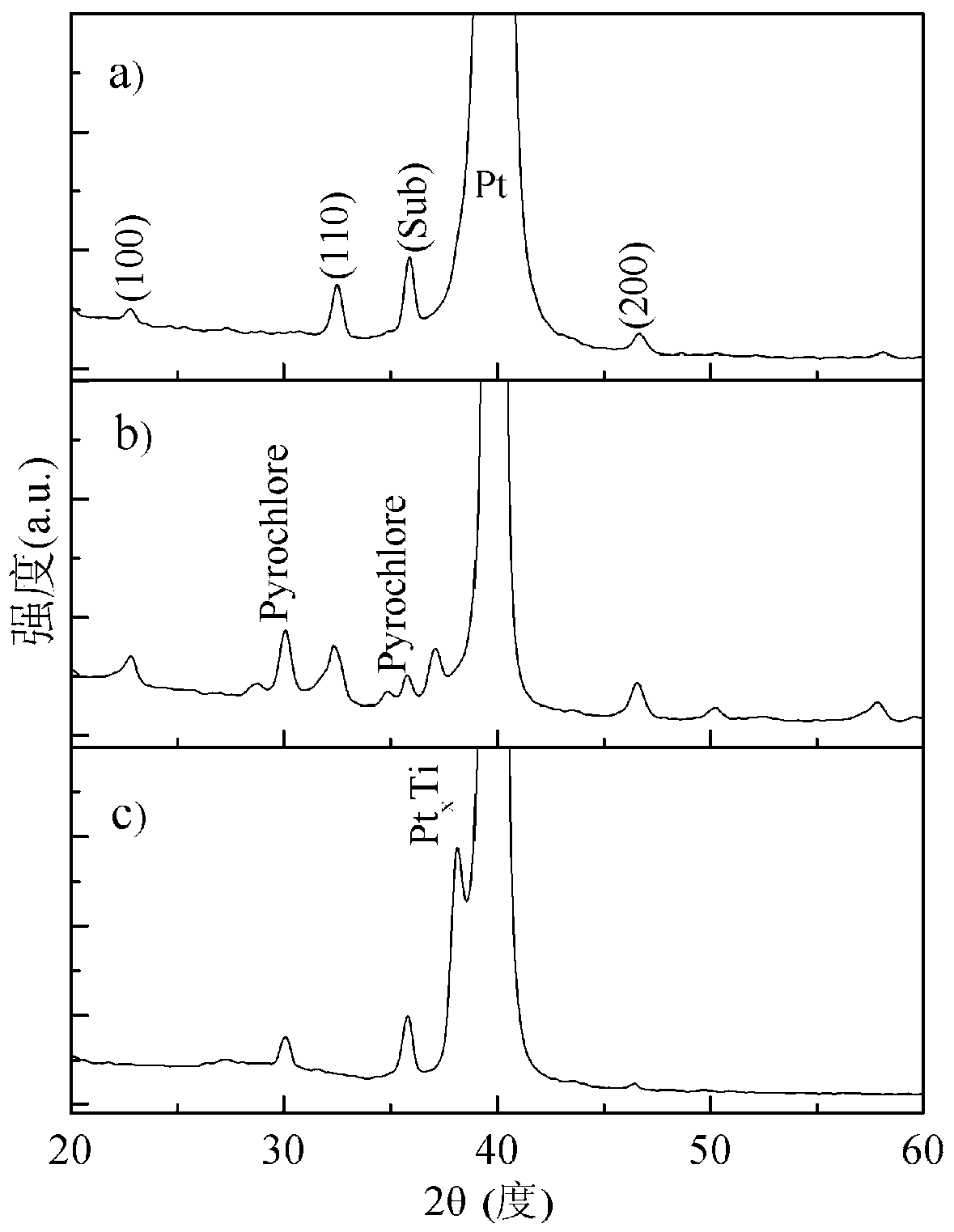

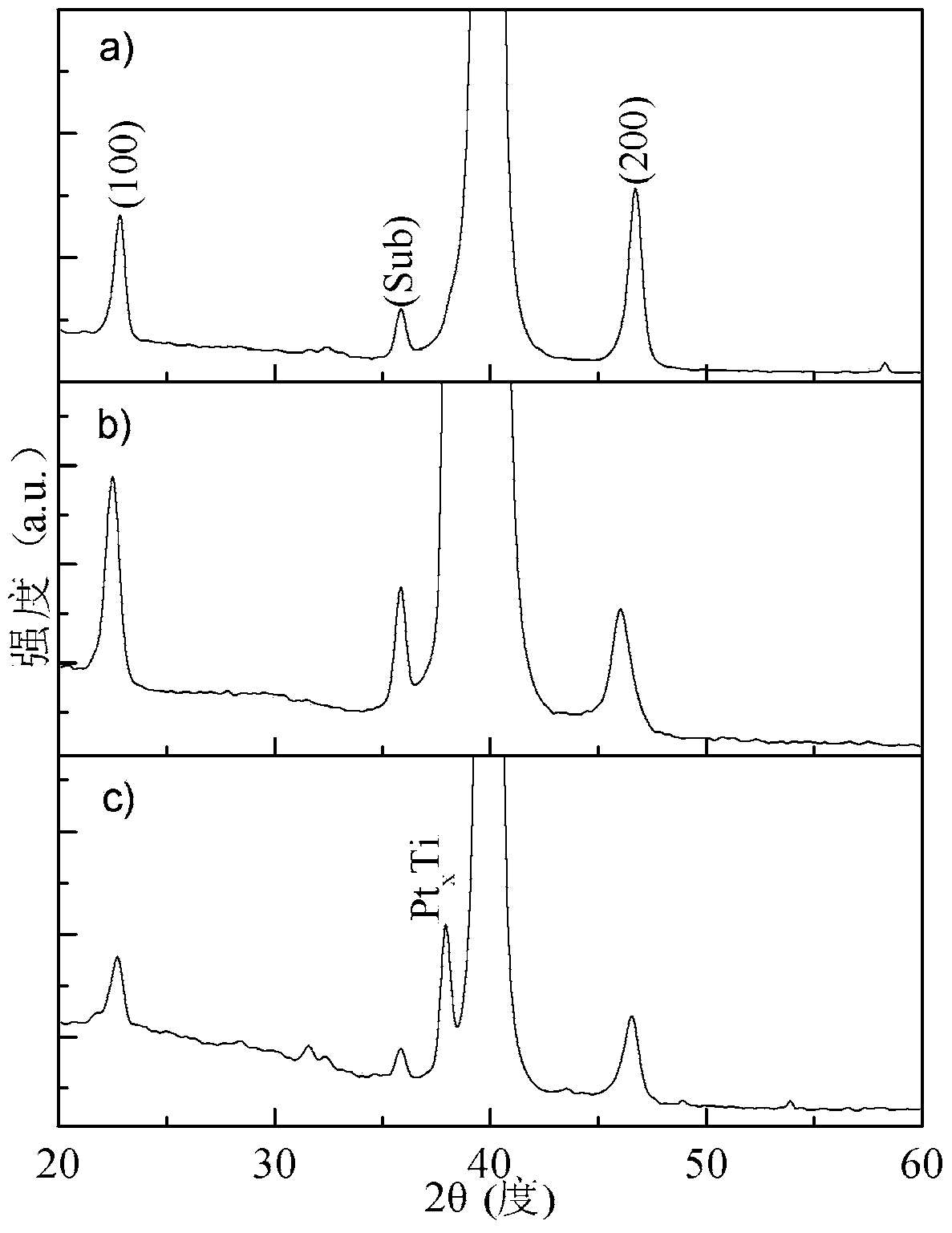

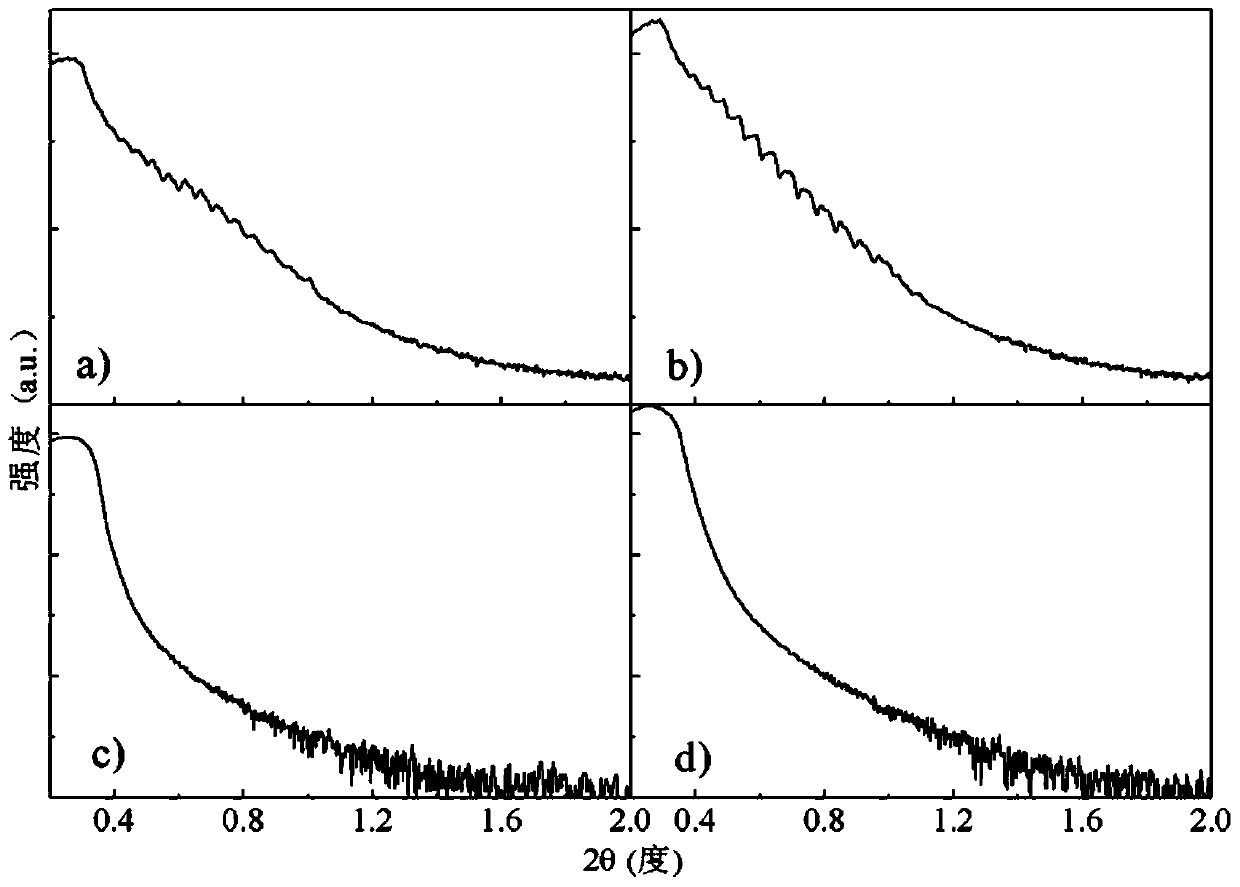

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: the preparation method of the lead-free piezoelectric thin film of this embodiment is as follows:

[0026] 1. Add sodium acetate, potassium acetate and bismuth nitrate to acetic acid, then stir for 20min to 40min at a temperature of 55°C to 65°C and a stirring speed of 500r / min to 700r / min to obtain A solution;

[0027] Add tetrabutyl titanate to the mixed solution of ethylene glycol methyl ether and acetylacetone, control the speed at room temperature to 500r / min-700r / min and stir for 20min-40min, then add formamide, and continue stirring for 20min-40min to obtain B solution;

[0028] Mix A solution and B solution cooled to room temperature to obtain C solution, then add ethylene glycol methyl ether, adjust the concentration of C solution to 0.2mol / L~0.3mol / L, and then control the stirring speed at room temperature to 500r / min~700r / min stirring for 20min~40min, then aging for 24h to obtain bismuth sodium potassium titanate sol,

[0029] Amon...

specific Embodiment approach 2

[0035] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the ratio of sodium acetate and acetic acid in step one is 0.048g g:1mL, the ratio of potassium acetate and acetic acid is 0.012g:1mL, the ratio of bismuth nitrate and acetic acid is 0.322g::1mL; the molar ratio of ethylene glycol methyl ether to tetrabutyl titanate is 4.61:1, the molar ratio of acetylacetone to tetrabutyl titanate is 1:1, the molar ratio of formamide to tetrabutyl titanate The molar ratio is 0.58:1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0036] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that in step 1, the temperature is 60° C. and the stirring speed is 600 r / min for 30 minutes to obtain A solution. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com