Graphene-based bismuth tungstate composite photocatalyst and its preparation method and application

A technology of alkenyl bismuth tungstate and photocatalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the problem of narrow ultraviolet spectrum and limited application of titanium dioxide, etc. problem, to achieve the effect of simple operation, simple and easy-to-operate preparation method, low-cost and high-yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

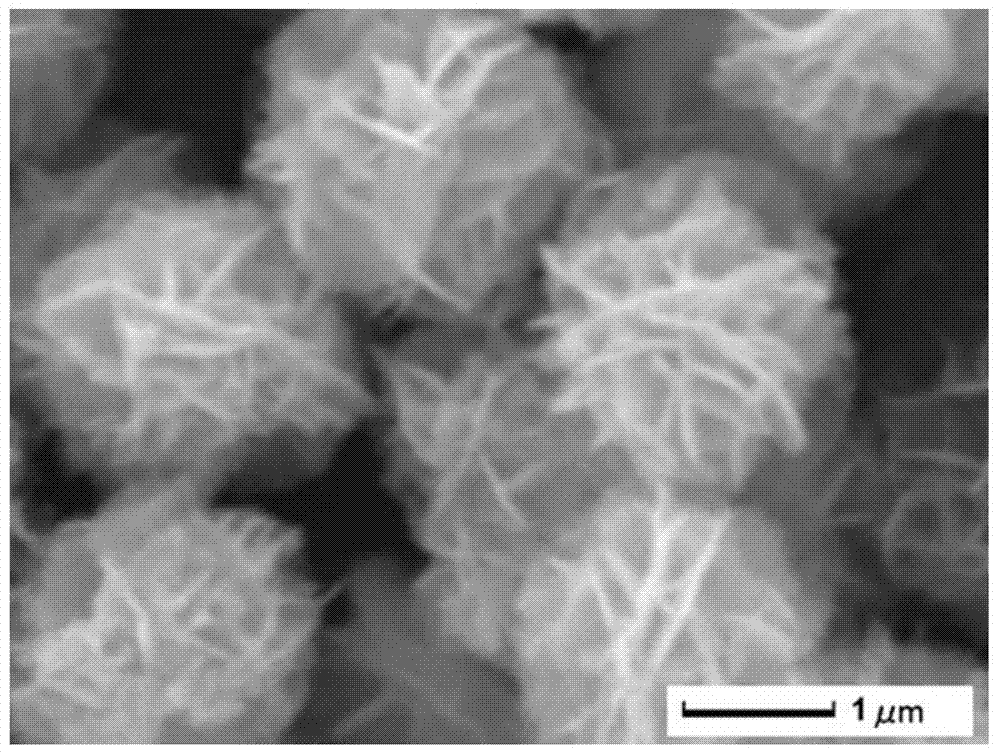

[0043] Dissolve 0.97g of bismuth nitrate pentahydrate in 10mL of glacial acetic acid, and record it as solution A; dissolve 0.33g of sodium tungstate dihydrate in 50mL of deionized water, and record it as solution B; add solution B to solution A and mix until uniform After mixing, transfer it to a stainless steel autoclave lined with polytetrafluoroethylene and react at 180°C for 3 hours. After naturally cooling to room temperature, filter and wash the solid on the filter paper in an oven at 60°C for 4 hours to obtain the following: figure 1 The white flower-like bismuth tungstate photocatalyst shown in the figure shows that the photocatalyst prepared by this method is assembled from nanosheets, with a uniform shape and a particle size of about 1.5 μm. .

[0044] Get 0.25g photocatalyst, take the ciprofloxacin hydrochloride of 250mL 10mg / L as target pollutant, adopt Figure 7 The shown device was subjected to photocatalytic degradation experiments under visible light. The exp...

Embodiment 2

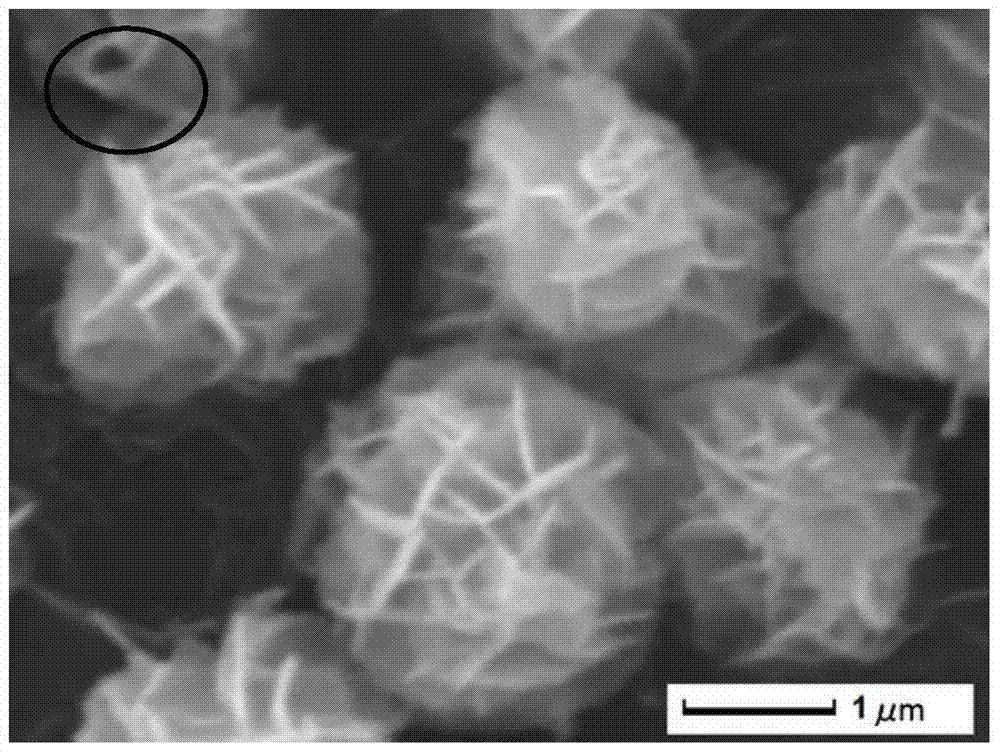

[0046] Dissolve 0.97g of bismuth nitrate pentahydrate in 10mL of glacial acetic acid, and record it as solution A; dissolve 0.33g of sodium tungstate dihydrate in 50mL of deionized water, and record it as solution B; add solution B to solution A and mix until uniform After mixing, transfer it to a stainless steel autoclave lined with polytetrafluoroethylene and react at 180°C for 3 hours. After cooling to room temperature naturally, filter and wash, and dry the solid on the filter paper in an oven at 60°C for 4 hours to obtain a white flower. Bismuth tungstate photocatalyst, denoted as C; 10mg of graphene oxide was added to 100mL of deionized water, the pH was adjusted to 7.5 with ammonia water and ultrasonically stripped for 120min, and the supernatant was centrifuged on a low-speed centrifuge and denoted as solution D. Then add 1g of flower-shaped bismuth tungstate to solution D, stir for 4 hours, and record it as solution E; add 0.2mL of hydrazine hydrate to solution E, and ...

Embodiment 3

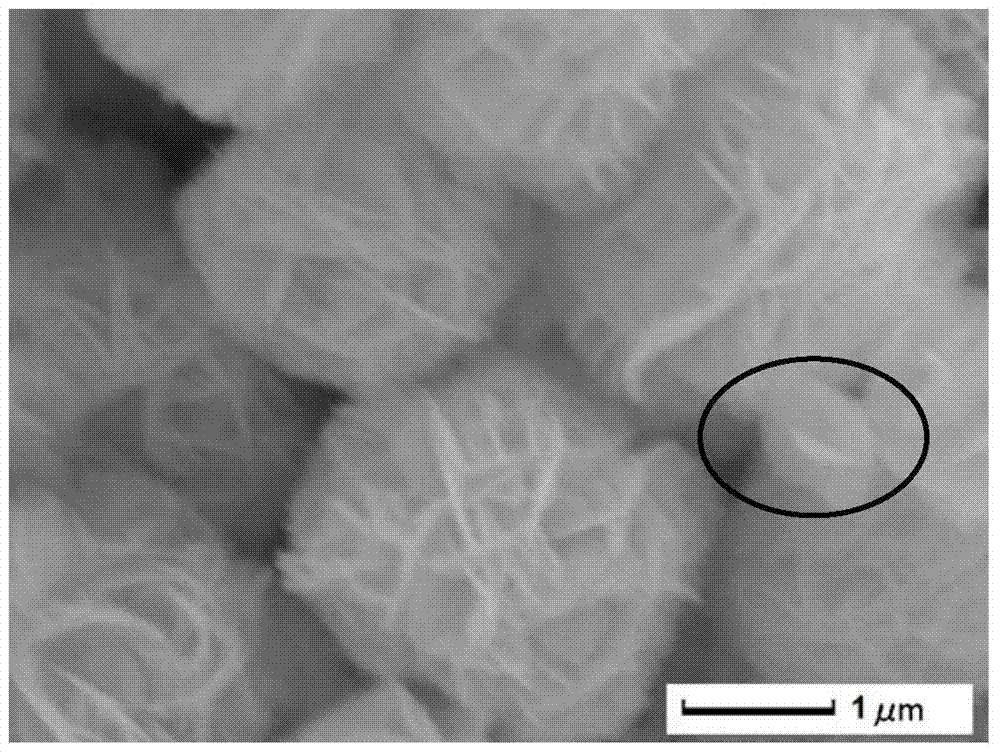

[0048] Dissolve 0.97g of bismuth nitrate pentahydrate in 10mL of glacial acetic acid, and record it as solution A; dissolve 0.33g of sodium tungstate dihydrate in 50mL of deionized water, and record it as solution B; add solution B to solution A and mix until uniform After mixing, transfer it to a stainless steel autoclave lined with polytetrafluoroethylene and react at 180°C for 3 hours. After cooling to room temperature naturally, filter and wash, and dry the solid on the filter paper in an oven at 60°C for 4 hours to obtain a white flower. Bismuth tungstate photocatalyst, denoted as C; 20mg of graphene oxide was added to 100mL of deionized water, the pH was adjusted to 7.5 with ammonia water and ultrasonically stripped for 120min, and the supernatant was centrifuged on a low-speed centrifuge and denoted as solution D. Then add 1g of flower-like bismuth tungstate to solution D, stir for 4 hours, and record it as solution E; add 0.4mL of hydrazine hydrate to solution E, and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com