Manganese based SCR catalyst for low temperature denitration and preparation method thereof

A low-temperature denitrification and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as poisoning and channel blockage, achieve good practicability, significant beneficial effects, and facilitate industrialization and application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

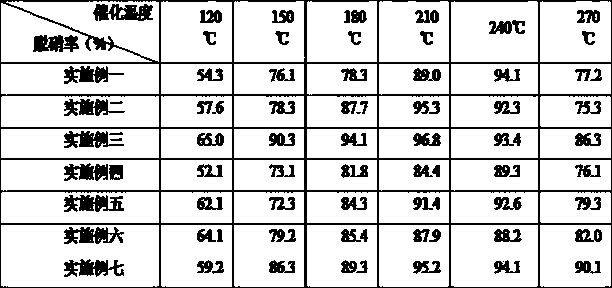

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing the manganese-based SCR low-temperature denitrification catalyst, comprising the following steps: step 1, dispersion of the carrier; step 2, preparation of sludge; step 3, drying and roasting;

[0034] In the step one, the carrier TiO 2 Ultrasonic dispersion in deionized water, the ultrasonic dispersion parameter is 100WHz ~ 200WHz for 1h ~ 6h, forming a uniform suspension, in which the carrier TiO 2 Can be nanoscale anatase TiO 2 , the nanoscale TiO 2 Higher dispersibility, Mn active components can be dispersed on the surface of the carrier in an amorphous state, improving catalytic activity;

[0035] In said step 2, according to the active component MnO 2 , CeO 2 , Nb 2 o 5 The mass percentages of the three are 3% to 10%: 0.1% to 2%: 0.1% to 1%. Weigh the corresponding mass of active precursors manganese nitrate, cerium nitrate, and niobium oxalate, slowly add them to the suspension in step 1, and then ...

Embodiment 1

[0040] Manganese-based SCR low-temperature denitration catalysts were prepared according to the following steps:

[0041] Step 1, the dispersion of the carrier, weigh 100g nano-scale anatase TiO 2 Carrier, dispersed in 150ml deionized water, 200WHz ultrasonic dispersion for 1h to form a uniform suspension;

[0042] Step 2, the preparation of mud, according to the active component MnO 2 , CeO2 , Nb 2 o 5 The three accounted for 5%, 1%, and 0.5% of the mass percentage of the catalyst product. Weighed the corresponding mass of active precursors manganese nitrate, cerium nitrate, and niobium oxalate, slowly added to the suspension in step 1, and then added 1g carboxymethyl fiber element and 1g polyoxyethylene, 10000rpm high-speed stirring for 3 hours to form a uniformly mixed mud;

[0043] Step 3, drying and roasting, put the sludge into an oven to dry at 110°C for 12 hours, and then put it into a muffle furnace and roast at 600°C for 6 hours to obtain a manganese-based SCR lo...

Embodiment 2

[0046] Manganese-based SCR low-temperature denitration catalysts were prepared according to the following steps:

[0047] Step 1, the dispersion of the carrier, weigh 100g nano-scale anatase TiO 2 Carrier, dispersed in 150ml deionized water, 100WHz ultrasonic dispersion for 6h to form a uniform suspension;

[0048] Step 2, the preparation of mud, according to the active component MnO 2 , CeO 2 , Nb 2 o 5 The three account for 5%, 2%, and 0.5% of the mass percentage of the catalyst product. Weigh the corresponding mass of active precursors manganese nitrate, cerium nitrate, and niobium oxalate, slowly add them to the suspension in step 1, and then add 0.5g carboxymethyl Cellulose and 0.5g polyethylene oxide, 3000rpm high-speed stirring for 6h, forming a uniformly mixed mud;

[0049] Step 3, drying and roasting, put the sludge into an oven to dry at 110°C for 10 hours, and then put it into a muffle furnace and roast at 600°C for 4 hours to obtain a manganese-based SCR low-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com