Purification treatment method of potato starch wastewater

A technology for purification of potato starch and wastewater, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of no potato starch wastewater treatment method, unable to maintain the survival of biological bacteria, and restrict the development of potato industry, etc., to achieve low treatment cost, The effect of low operation and maintenance costs and low equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

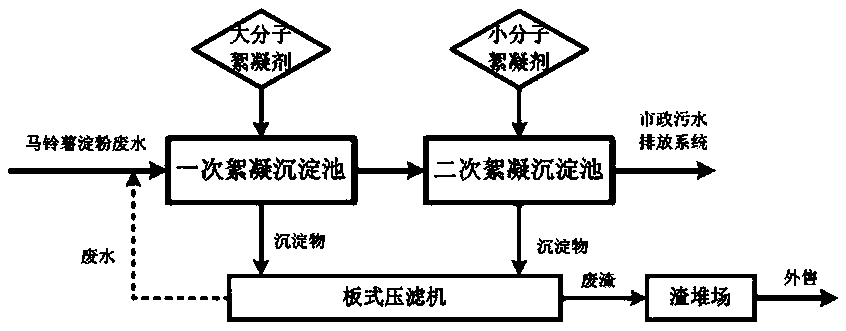

Method used

Image

Examples

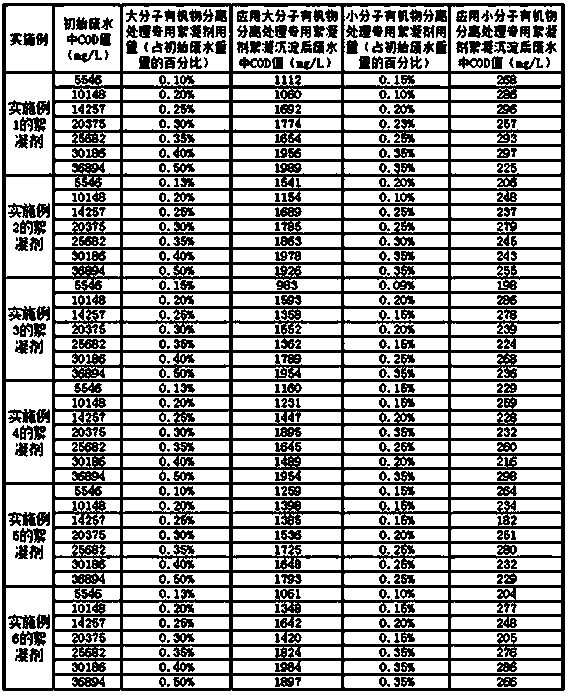

Embodiment 1

[0036] The special flocculant for the separation and treatment of macromolecular organic matter of the present invention is composed of the following components in mass percentage:

[0037]Ultrafine attapulgite 26%, polyacrylamide 18%, ferric chloride 8%, urea 10%, polyaluminum chloride 16%, polyferric sulfate 21% and natural cationic polysaccharide chitosan 1%.

[0038] The above-mentioned components are mixed evenly to obtain a special flocculant for the separation and treatment of macromolecular organic matter.

[0039] The special flocculant for the separation and treatment of small molecule organic matter of the present invention is composed of the following components in mass percentage:

[0040] Chitosan 26%, aluminum sulfate 12%, ferric chloride 12%, polyacrylamide 20%, acetic acid 10%, polyaluminum chloride 10%, alum 10%.

[0041] The above-mentioned components are mixed evenly to obtain a special flocculant for the separation and treatment of small molecular organic...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is:

[0044] The special flocculant for the separation and treatment of macromolecular organic matter is composed of the following components in mass percentage: 30% ultra-fine attapulgite, 22% polyacrylamide, 6% ferric chloride, 8% urea, 15% polyaluminum chloride, polysulfuric acid Iron 17% and natural cationic polysaccharide chitosan 2%.

[0045] The special flocculant for the separation and treatment of small molecule organic matter is composed of the following components in mass percentage: 25% chitosan, 14% aluminum sulfate, 15% ferric chloride, 18% polyacrylamide, 8% acetic acid, and 8% polyaluminum chloride %, alum 12%.

[0046] All the other parts are the same as in Example 1.

Embodiment 3

[0048] The difference between this embodiment and embodiment 1 is:

[0049] The special flocculant for the separation and treatment of macromolecular organic matter is composed of the following components in mass percentage: ultrafine attapulgite 25%, polyacrylamide 18%, ferric chloride 8%, urea 12%, polyaluminum chloride 19%, polysulfuric acid Iron 17% and natural cationic polysaccharide chitosan 1%.

[0050] The special flocculant for the separation and treatment of small molecule organic matter is composed of the following components in mass percentage: 30% chitosan, 10% aluminum sulfate, 10% ferric chloride, 22% polyacrylamide, 8% acetic acid, 12% polyaluminum chloride %, alum 8%.

[0051] All the other parts are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com