Method for producing hydrogen by converting membrane separation impermeable gas obtained after membrane separation of oil wash dry gas used in coal liquefaction project

A non-permeable gas and membrane separation technology, applied in the field of coal-to-oil, can solve the problems of low comprehensive hydrogenation conversion rate, multiple fuels, consumption, etc., to reduce the risk of metal powderization, reduce the probability of carbon black generation, and process routes simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

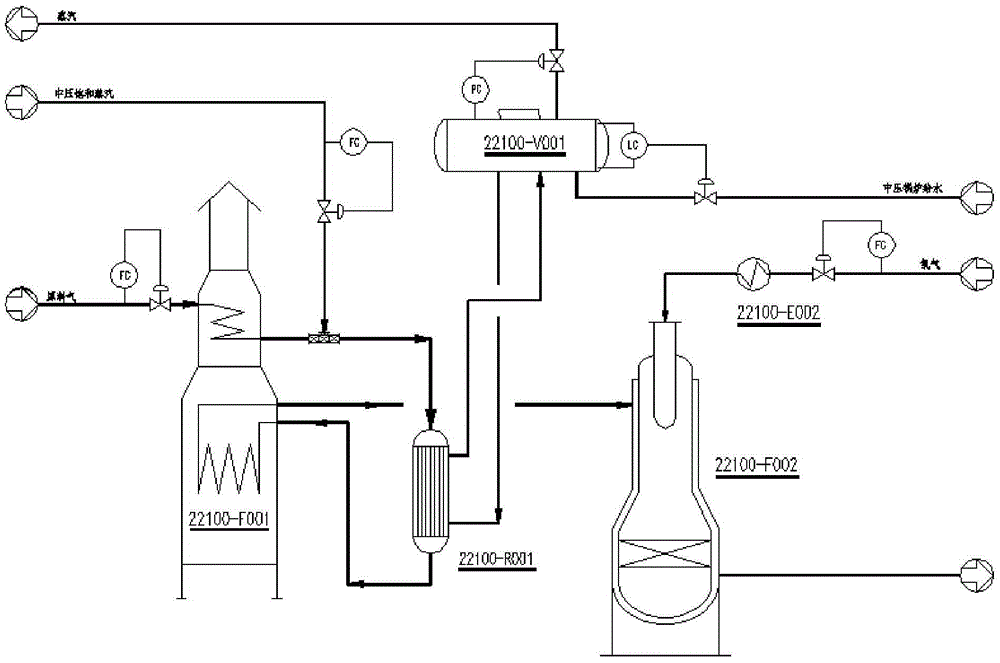

[0051] Combine below figure 1 , figure 2 The present invention is further described:

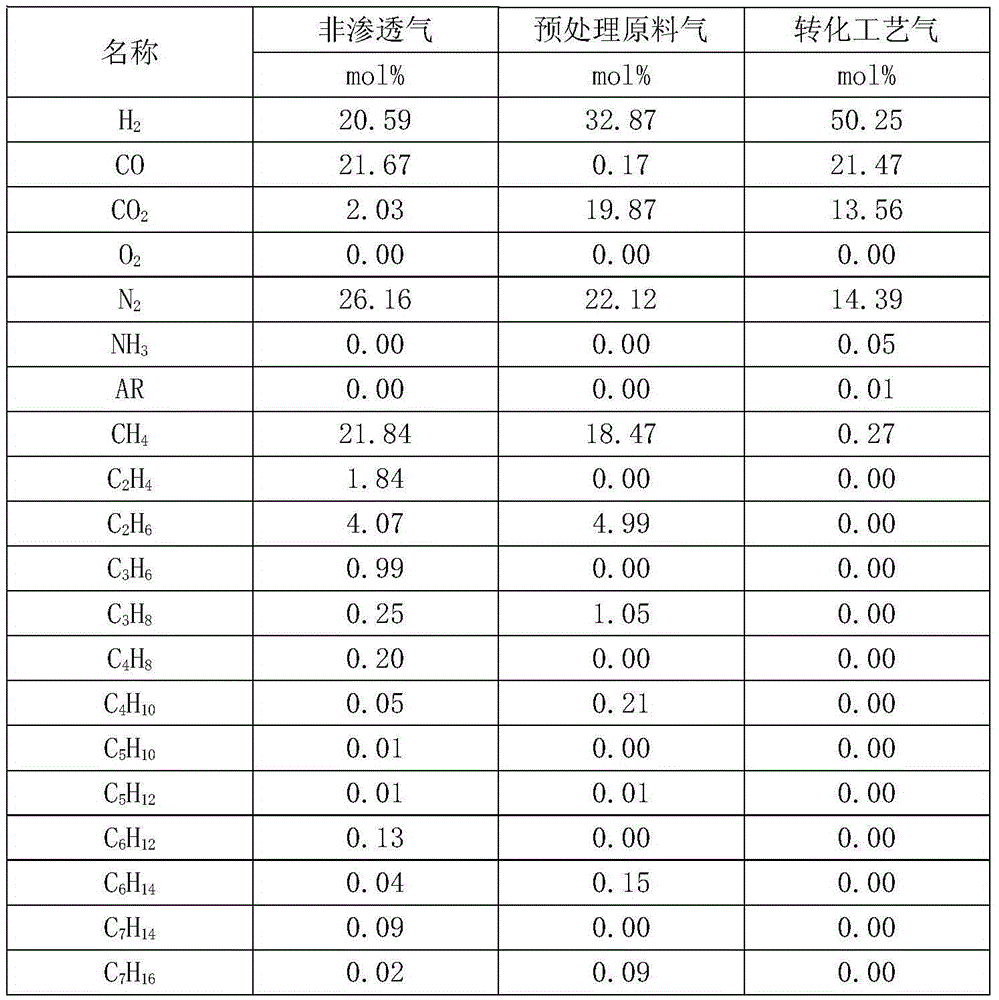

[0052] After the oil-washed dry gas is separated by membrane, the membrane-separated non-permeable gas raw material gas is preheated by the heating furnace, and then added with medium-pressure steam according to the molar ratio of raw material gas to steam of 1:1, and then sent to the pretreatment reactor. Under the action of the pretreatment catalyst, the unsaturated hydrocarbons in the hydrogenation reaction occur, and the CO shift reaction occurs at the same time; the raw material gas after the reaction is sent to the radiant section coil of the heating furnace to be heated to 450 °C, and then feeds to the reformer. The reaction equilibrium is reached in 1-3 seconds, and the hydrogen-rich process gas is produced, and then the final product hydrogen is obtained through conversion and hydrogen extraction.

[0053] The total molar content of higher hydrocarbons contained in the feed gas o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com