Quinoxaline diamine type polybenzoxazine foam material and preparation method

A technology of quinoxaline diamine type and polybenzoxazine, which is applied in the field of organic polymer materials, can solve the problems of rare reports on benzoxazine foam materials, achieve simple preparation methods, excellent flame retardant properties, The effect of good heat resistance and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

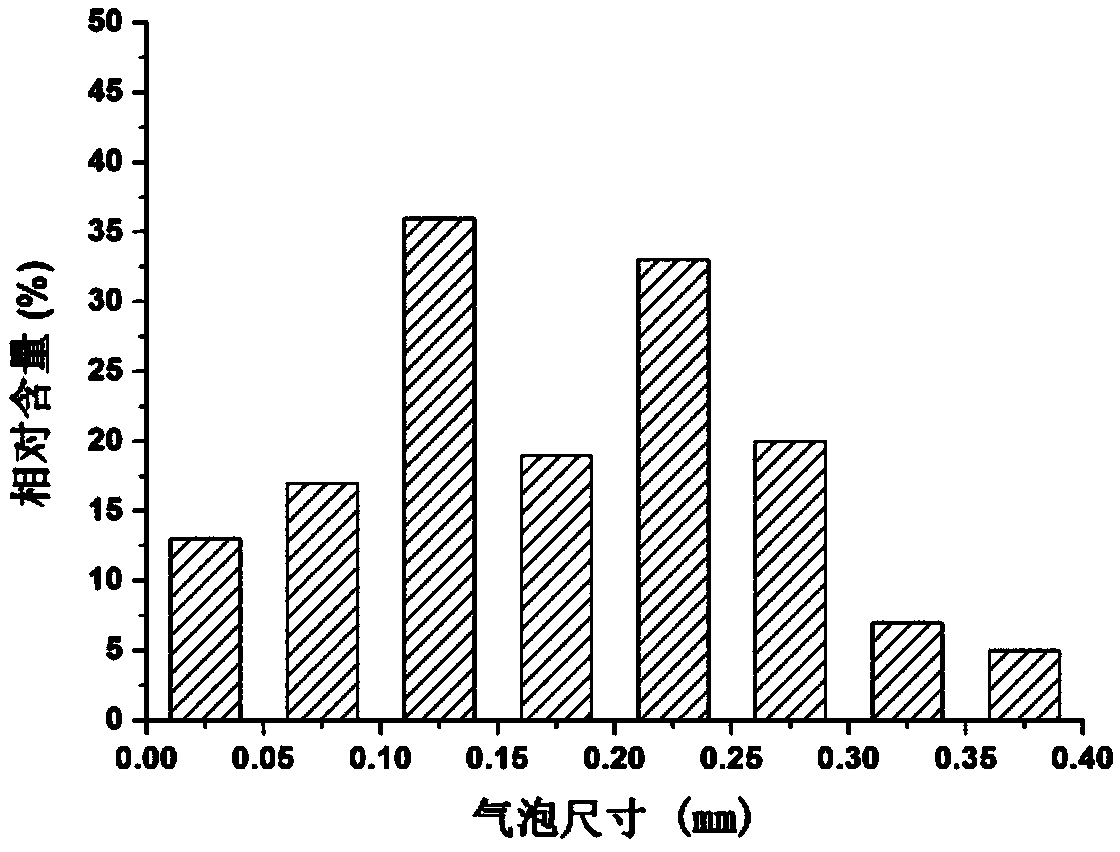

Image

Examples

Embodiment 1

[0023] (1) Add 3-dinitrobenzil (30.0g) and o-phenylenediamine (11.9g) and 50mL of glacial acetic acid to a three-necked flask respectively, and the mixture is refluxed for 7h, then cooled to room temperature, and the formed Precipitate, dry, and recrystallize the obtained crude product twice with glacial acetic acid to obtain 2,3-bis(3-nitrophenyl)quinoxaline with a yield of 85.2%;

[0024] (2) 2,3-bis(3-nitrophenyl)quinoxaline (18.6g) and palladium carbon catalyst (0.7g) were added in 300mL ethanol, then 80% hydrazine hydrate (8.8g) was added dropwise , reacted at reflux temperature for 8 hours, filtered while it was hot, removed the palladium carbon catalyst, cooled the filtrate to room temperature, precipitated crystals, filtered, washed with distilled water for 3 to 4 times, and finally dried in vacuum to obtain 2,3-bis(3- Aminophenyl) quinoxaline, yield 91.2%;

[0025] (3) Add 50mL xylene, 2,3-bis(3-aminophenyl)quinoxaline (15.6g), phenol (9.4g) and polymer Formaldehyde...

Embodiment 2

[0029] Except that the phenol in the synthesis step (3) is replaced by 4-phenoxyphenol (18.6g), other conditions are the same as in Example 1 to obtain the p-phenoxyphenol-quinoxalinyl benzoxazine monomer with a yield of 78.3 %; Proton NMR spectrum test result (500M, CDCl 3 , ppm): 6.55~8.16 (m, 28H, Ar-H), 5.10 (s, 4H, O-CH 2 -N), 4.28(s,4H,Ar-CH 2 -N); infrared spectrum test results (KBr, cm -1 ): 1321, 1234, 1070, 1160 and 947.

[0030] The curing and testing conditions were the same as in Example 1, and the polybenzoxazine foam Poly(B-DAMQ-p-pop) was obtained, and the properties are shown in Table 1.

Embodiment 3

[0032] Except that the phenol in the synthesis step (3) is replaced by 4-methoxyphenol (12.4g), other conditions are the same as in Example 1 to obtain the p-methoxyphenol-quinoxalinyl benzoxazine monomer with a yield of 78.3 %; Proton NMR spectrum test result (500M, CDCl 3 , ppm): 6.56~8.17 (m, 18H, Ar-H), 5.08 (s, 4H, O-CH 2 -N), 4.29(s, 4H, Ar-CH 2 -N), 3.75(s, 6H, -OCH 3 ); infrared spectrum test results (KBr, cm -1 ): 1322, 1233, 1073, 1158 and 950.

[0033] The curing and testing conditions were the same as those in Example 1, and finally the benzoxazine foam Poly(B-DAMQ-p-omp) was obtained, and the properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com