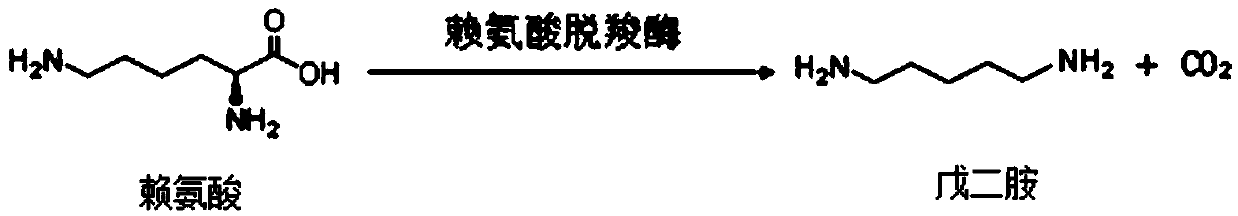

Genetically engineered bacterium for producing pentamethylene diamine and method for preparing pentamethylene diamine

A technology of genetically engineered bacteria and pentamethylenediamine, applied in the field of microorganisms, can solve problems such as no technical innovation research, and achieve the effect of protecting catalyst activity, realizing repeated use and efficient transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

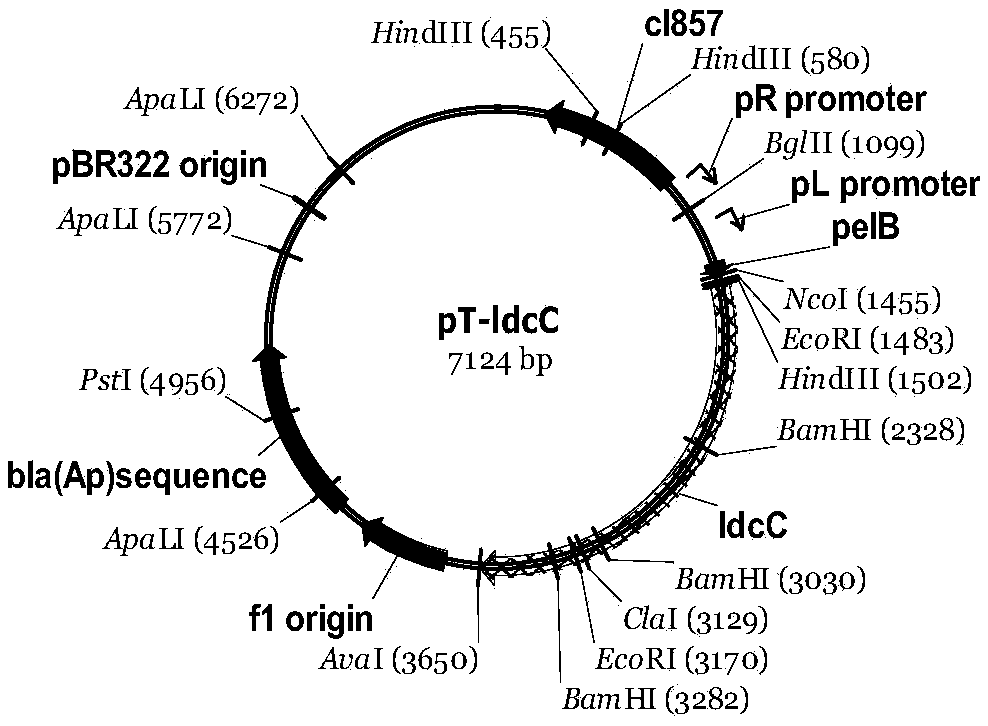

[0038] Example 1: Escherichia coli chromosome lysine decarboxylase temperature-regulated promoter and replacement of signal peptide

[0039] 1. Cloning of partial sequence of ldcC gene

[0040] Using Escherichia coli B0013-070 chromosomal DNA as a template, primers ldc-up1 (SEQ ID NO: 3) and ldc-up2 (SEQ ID NO: 4) were used to amplify the 5' end of ldcC and its upstream sequence (ldcC-up) by PCR. Primers add EcoRI sites. The size of the PCR product is ~920bp; the PCR product is cloned into pMD-18T-simple to obtain the recombinant plasmid pLDC-UP;

[0041] ldc-up1:G GAATTC GCAACCTGCGTGAAATGTC; EcoRI

[0042] ldc-up2:G GAATTC TGAACGGCGGTGTAATGTT; EcoRI

[0043] 2. Obtaining homology arms of ldcC gene recombination

[0044] EcoRI digestion of the recombinant plasmid pLDC-UP releases 915bp and 2.7kb fragments; using the DNA of the recombinant plasmid pLDC-up as a template, reverse PCR amplification was performed with primers ldc-invF (SEQ ID NO: 5) and ldc-invR (SEQ ID NO: 6...

Embodiment 2

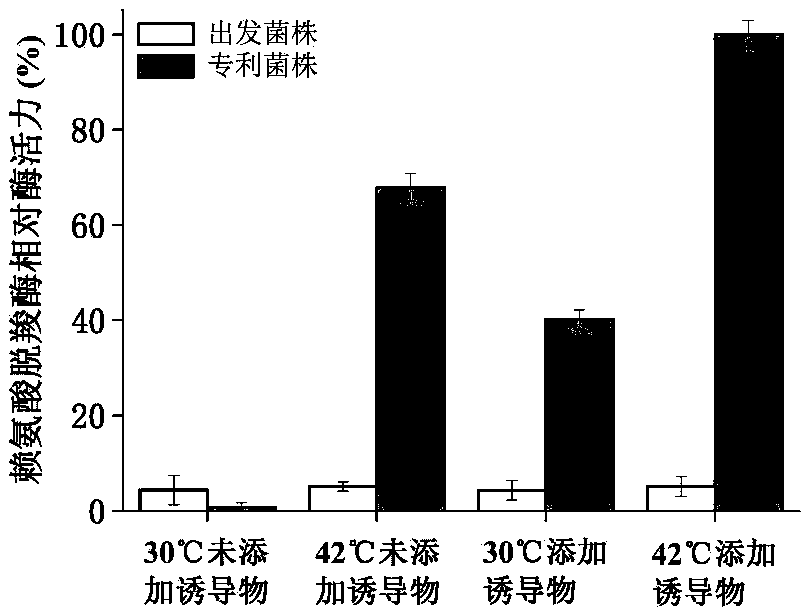

[0059] Embodiment 2: p in strain 42# (pT-ldcC) R -p L Determination of promoter activity

[0060] The patented strain 42# (pT-ldcC) and the original strain B0013-070 were cultured at 25-36°C and 37-50°C for 2-10 hours, and the culture medium was (g / L): yeast extract 15, peptone 0.5, anhydrous MgSO 4 0.25, glucose 5. And measure their cell disruption liquid lysine decarboxylase (LDC) specific enzyme activity, typical result is as image 3 shown. The preparation process of the cell disruption solution is as follows: put 30mL fermentation broth in a 50mL centrifuge tube, centrifuge at 6000rpm for 8min; discard the supernatant, add 10mLddH 2 O, vortex to mix, add ddH 2 From 0 to 30 mL, centrifuge at 6000 rpm for 8 min; discard the supernatant, add 10 mL of PBS, vortex to mix, add PBS to 30 mL, and centrifuge at 6000 rpm for 8 min. Repeat washing the cells 1x. Add 10mL PBS to resuspend the bacteria, and ultrasonically disrupt. (Sonication conditions: ultrasonication for 3s...

Embodiment 3

[0062] Example 3 Identification of bacterial strain 42# (pT-ldcC) cell activity and secretion expression process of lysine decarboxylase

[0063] The patented strain 42# (pT-ldcC) and the original strain B0013-070 were cultured at 25-36°C and 37-50°C for 2-10 hours, and the culture medium was (g / L): yeast extract 0-20, peptone 0- 20, anhydrous MgSO 4 0-10, glucose 5. And the expression process of lysine decarboxylase was strengthened by adding lactose, IPTG, etc. The fermentation broth was centrifuged at 6000rpm for 8min, and the supernatant was taken to directly measure the enzyme activity as the enzyme activity in the fermentation broth; the enzyme activity measured after the cells collected by centrifugation were resuspended in the medium to the initial volume was taken as the enzyme activity of the periplasmic space; The measured enzyme activity was taken as the total enzyme activity in the periplasmic space and in the cell. A typical measurement result is as Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com