Animal feed and preparation method thereof

A technology of animal feed and feed, which is applied in the preparation of animal feed and in the field of animal feed, can solve the problems of limited energy and nutrition, and the utilization of feed is only 300 million tons, so as to promote growth and development, improve feed intake and digestion and absorption rate , Improving the effect of immunity and disease resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

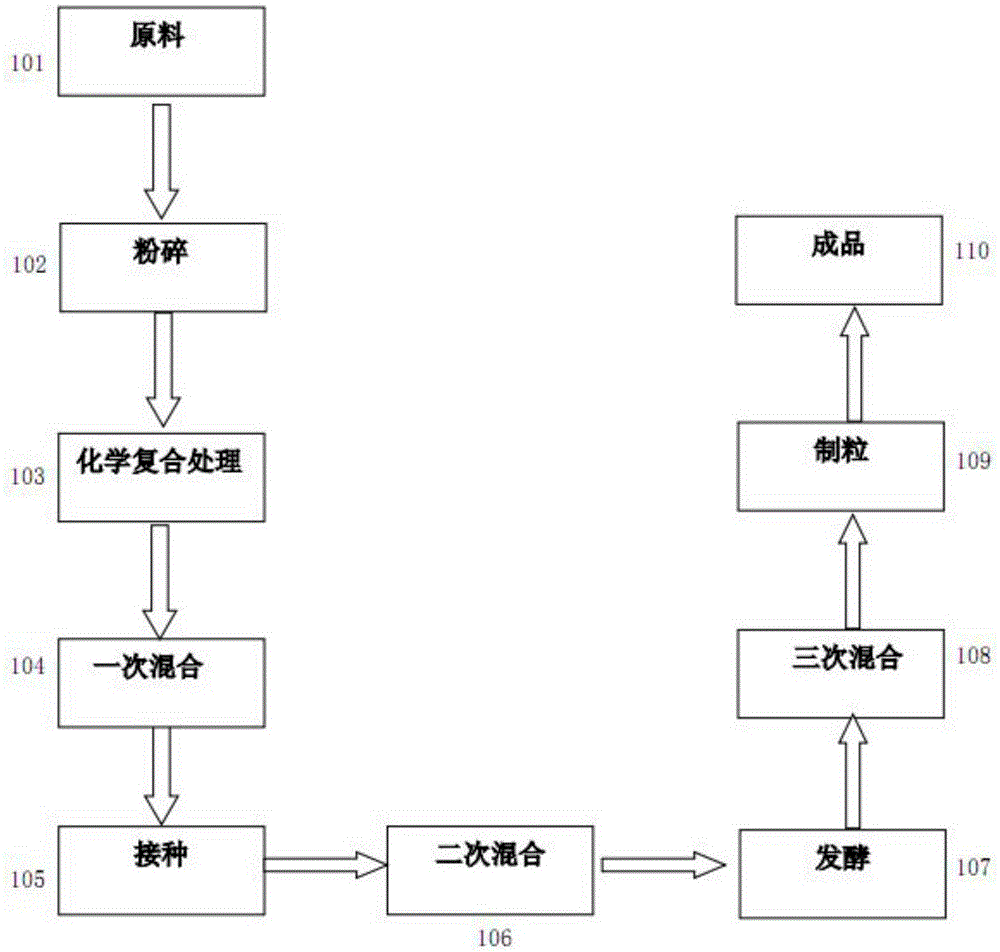

[0042]A method for preparing animal feed is to combine chemical compound treatment 103 and biological fermentation 107 to prepare animal feed, and its specific operation process includes the following steps:

[0043] 1) Use a high-speed rotary pulverizer to pulverize the corn stalk raw material 101 by 102 to 20 meshes, and then perform chemical compound treatment 103, and mix the pulverized corn stalk powder with 2.5% urea, 3% Calcium hydroxide and 0.3% sodium chloride are mixed together 104 evenly, and reacted for 20 days at a reaction temperature of 25-30° C. to obtain chemically compounded 103 corn stalk powder;

[0044] 2) Prepare microbial mixed bacterial liquid and biological enzyme mixed liquid, the amount of inoculating 105 mixed bacterial liquid is 0.02% according to the mass percentage of corn stalk powder; The amount of biological enzyme enzyme solution added is 0.5%; at the same time, glucose, potassium dihydrogen phosphate, magnesium sulfate, ferrous sulfate, mult...

Embodiment 2

[0047] A method for preparing animal feed is to combine chemical compound treatment 103 and biological fermentation 107 to prepare animal feed, and its specific operation process includes the following steps:

[0048] 1) Use a high-speed rotary pulverizer to pulverize the corn stalk raw material 101 by 102 to 20 meshes, and then perform a chemical compound treatment 103, and mix the pulverized corn stalk powder with 3.5% urea, 4% Calcium hydroxide and 0.4% sodium chloride are mixed together 104 evenly, and reacted for 25 days at a reaction temperature of 25-30° C. to obtain chemical composite treatment 103 corn stalk powder;

[0049] 2) Prepare microbial mixed bacterial liquid and biological enzyme mixed liquid, the amount of inoculating 105 mixed bacterial liquid is 0.03% according to the mass percentage of corn stalks; The amount of enzyme enzyme solution added is 0.6%; at the same time, glucose, potassium dihydrogen phosphate, magnesium sulfate, ferrous sulfate, multivitami...

Embodiment 3

[0052] A method for preparing animal feed is to combine chemical compound treatment 103 and biological fermentation 107 to prepare animal feed, and its specific operation process includes the following steps:

[0053] 1) Use a high-speed rotary pulverizer to pulverize the corn stalk raw material 101 by 102 to 20 meshes, and then perform chemical compound treatment 103, and mix the pulverized corn stalk powder with 4% urea and 5% Calcium hydroxide and 0.5% sodium chloride are mixed together 104 evenly, and reacted for 30 days at a reaction temperature of 25-30° C. to obtain chemically compounded 103 corn stalk powder;

[0054] 2) Prepare microbial mixed bacterial liquid and biological enzyme mixed liquid, the amount of inoculating 105 mixed bacterial liquid is 0.04% according to the mass percentage of corn stalks; according to the mixed total mass of mixed bacterial liquid and chemical composite treatment 103 corn stalk powder The amount of biological enzyme enzyme solution add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com