Hot dip galvanizing coating chromate-free passivation agent and preparation method thereof

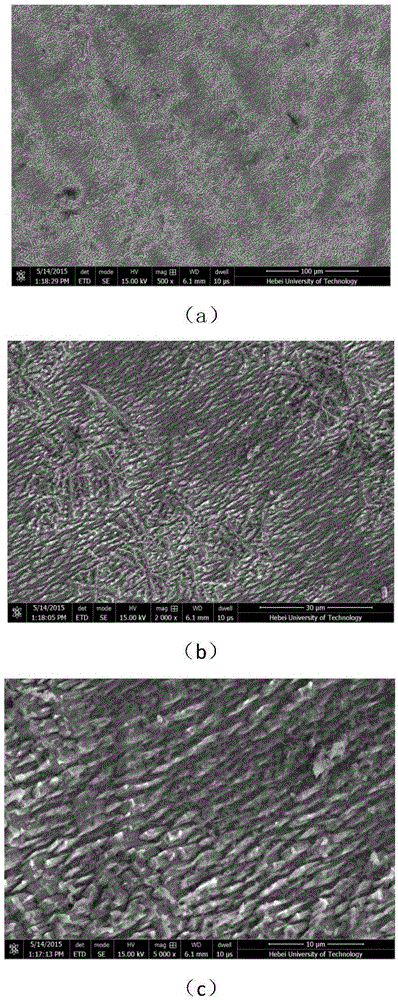

A chromium-free passivation agent, hot-dip galvanizing technology, applied in the direction of metal material coating technology, etc., can solve the problem of poor corrosion resistance of the surface film layer of microstructure, poor corrosion resistance of workpiece passivation film layer, silicate Uneven passivation film and other problems, to achieve the effect of smooth and dense passivation film, bright and smooth coating, and less defects

Active Publication Date: 2016-03-09

HEBEI UNIV OF TECH

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The disadvantage of the second type of chromium-free passivation agent is that the passivation film layer of the workpiece is thin and has poor corrosion resistance.

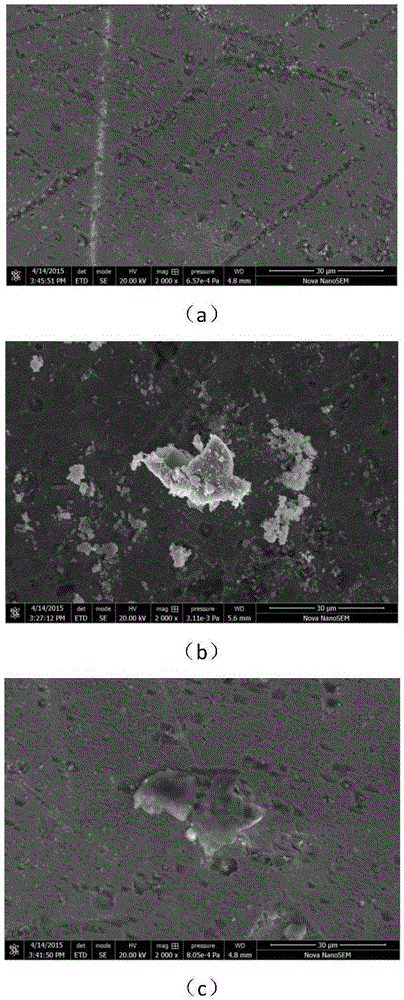

The shortcoming of this chromium-free passivating agent is that in use, there will be uneven silicate passivation film, large granular substances appear on the surface, and there are cracks in the film (such as figure 2 ), the roughness and unevenness of the microstructure directly lead to the poor corrosion resistance of the surface film of the hot-dip galvanized product, the time of rusting in salt water is accelerated, and the rusting area is rapidly expanded

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-8

[0041] The passivators of Examples 1-8 were prepared according to the above-mentioned preparation method.

[0042] The concrete formula of embodiment 1~8 is shown in Table 1, and M represents cobalt sulfate in the table, and N represents nickel sulfate,

[0043] Table 1

[0044]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a hot dip galvanizing coating chromate-free passivation agent and a preparation method thereof. Preparation of 1 l of the passivation agent is taken as an example, and the formula of the passivation agent comprises 8-40 g of sodium silicate, 20-40 g of sodium tungstate, 3-10 g of fluotitanic acid, 20-60 g of hydrogen peroxide, 3-7 mL of nitric acid, 3-7 mL of phosphoric acid, 1-6 g of film formation accelerant and the balance water. At least one of cobaltous sulfate and nickel sulfate serves as the film formation accelerant. The passivation agent is low in cost and simple in process, the environment cannot be danaged, and the passivation agent is more suitable for industrial application and popularization. A passivation film layer formed through the passivation agent is even, compact, bright, attractive and good in corrosion resistance.

Description

technical field [0001] The invention relates to surface treatment technology, in particular to a chromium-free passivator for a hot-dip galvanized layer and a preparation method thereof. Background technique [0002] With the progress of society and industrial development, the requirements for the surface properties of various equipment parts are getting higher and higher. Improving the surface properties of materials will effectively prolong their service life, save resources, increase productivity, and reduce environmental pollution. The biggest advantage of surface treatment technology is that it can prepare a thin layer of surface function that is superior to the performance of the base material in a variety of ways, so that the parts have higher wear resistance, self-lubrication, corrosion resistance and high temperature resistance than the base material. and other capabilities. Surface treatment technology includes many kinds, chrome-free passivation is one of them. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C22/44

CPCC23C22/44

Inventor 范永哲王凯甜温鸣马瑞娜杜安

Owner HEBEI UNIV OF TECH

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com