A kind of primary wood pulp cardboard and preparation method thereof

A technology of primary wood pulp and cardboard, applied in special paper, chemical instruments and methods, paper, etc., can solve the problems of high paper cost, rough surface of cardboard, lint and powder loss of paper, etc., and achieve extreme printing adaptability Poor, improve food hygiene level, reduce the effect of environmental pollution pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

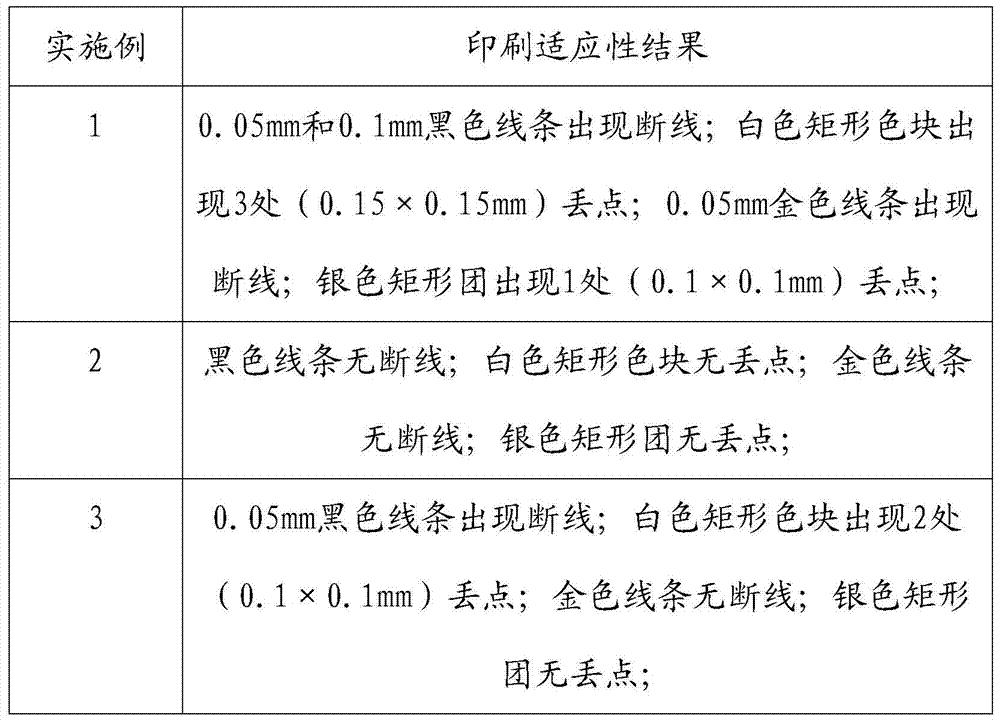

Embodiment 1

[0022] Such as figure 1 As shown, the raw wood pulp cardboard described in this embodiment is composed of three layers of paper, which are the surface layer 1, the core layer 2 and the bottom layer 3 respectively. Concrete preparation steps are:

[0023] (1) Crushing and refining: the pulp block is crushed with a D-type hydraulic pulper; after the surface layer and bottom layer slurry is removed by a high-concentration desander, it is refined with three double-disc refiners in series. Its freeness is controlled at 280csf for standby; the core layer slurry is set aside after the freeness is controlled at 220csf by a fine grinder;

[0024] (2) Color control: use wormwood extract for dyeing to ensure the same color of different production batches of raw wood pulp tobacco packaging cardboard;

[0025] (3) Fourdrinier + top wire forming: Top wire forming is used to increase the Z-direction fiber distribution of the paper sheet. The weight of the surface layer is controlled at 48g...

Embodiment 2

[0031] Such as figure 1 As shown, the raw wood pulp cardboard described in this embodiment is composed of three layers of paper, which are the surface layer 1, the core layer 2 and the bottom layer 3 respectively. Concrete preparation steps are:

[0032] (1) Crushing and refining: the pulp block is crushed with a D-type hydraulic pulper; after the surface layer and bottom layer slurry is removed by a high-concentration desander, it is refined with three double-disc refiners in series. Its freeness is controlled at 325csf for standby; the core layer slurry is set aside after the freeness is controlled at 300csf by a fine grinder;

[0033] (2) Color control: Dyeing with the extract of plane grass to ensure the same color of different production batches of raw wood pulp tobacco packaging cardboard;

[0034] (3) Fourdrinier + top wire forming: Top wire forming is used to increase the fiber distribution in the Z direction of the paper sheet. The basis weight of the surface layer ...

Embodiment 3

[0040] Such as figure 1 As shown, the raw wood pulp cardboard described in this embodiment is composed of three layers of paper, which are the surface layer 1, the core layer 2 and the bottom layer 3 respectively. Concrete preparation steps are:

[0041] (1) Crushing and refining: the pulp block is crushed with a D-type hydraulic pulper; after the surface layer and bottom layer slurry is removed by a high-concentration desander, it is refined with three double-disc refiners in series. Its freeness is controlled at 350csf for standby; the core layer slurry is set aside after the freeness is controlled at 380csf by a fine grinder;

[0042] (2) Color control: Dyeing is carried out with the extract of the grass to ensure that different production batches of raw wood pulp tobacco packaging cardboard have the same color;

[0043] (3) Fourdrinier + top wire forming: Top wire forming is used to increase the fiber distribution in the Z direction of the paper sheet. The weight of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com