Oil field crude oil pour point depressant and preparing method thereof

A crude oil pour point depressant and oil field technology, which is applied in mechanical equipment, gas/liquid distribution and storage, pipeline systems, etc., can solve the problem of large pour point depressant range, small dosing amount, and unsatisfactory crude oil pour point depressant in offshore oilfields, etc. problem, to achieve the effect of enhanced shear resistance, simple process, and easy control of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

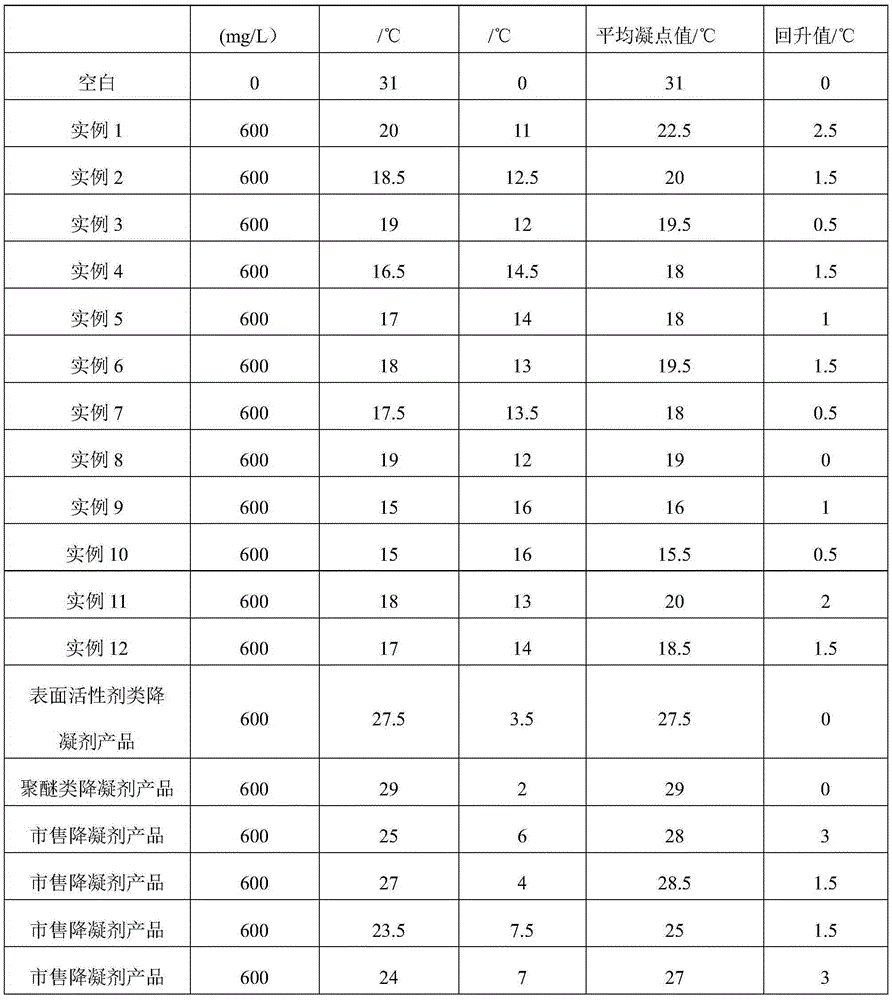

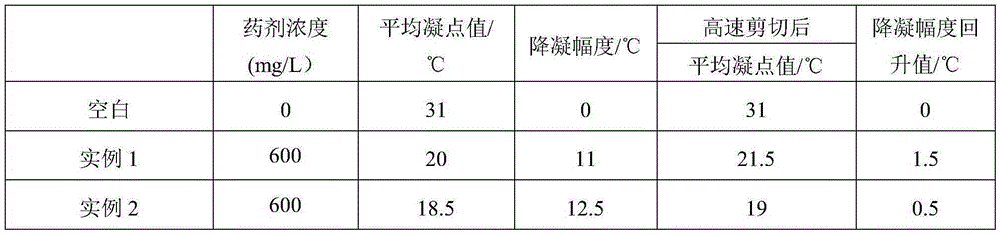

Examples

Embodiment 1

[0043](1) 296.5g hexadecyl acrylate, 518.2g2-perfluorooctyl ethyl acrylate, and 1222.1g xylene are mixed earlier (wherein the mass ratio of hexadecyl acrylate and perfluorooctyl ethyl acrylate is 1:1), warming up to 60°C, stirring for 1h;

[0044] (2) Then add 52.1g of styrene (the molar ratio of cetyl acrylate to styrene is 2:1), turn on nitrogen protection, heat up to 85°C, and add dropwise toluene containing 3.5g of benzoyl peroxide solution, after reacting for 12 hours, product A was obtained;

[0045] (3) Mix 1% of the poly-alkene by the mass of the product A, 5% of the ethylene-vinyl acetate copolymer by the mass of A with A, and stir evenly to obtain the oil field crude oil pour point depressant.

Embodiment 2

[0047] (1) first mix 268.4g myristyl acrylate, 106g2-perfluorobutyl ethyl acrylate, and 374.4g trimethylbenzene (wherein the substance ratio of myristyl acrylate to perfluorobutyl ethyl acrylate is 3 : 1), be warming up to 50 ℃, stir 1h;

[0048] (2) Then add 104.2g of styrene (the ratio of tetradecyl acrylate to styrene is 1:1), turn on the nitrogen protection, heat up to 60°C, and add 1.2g of azobisisobutyronitrile dropwise. Xylene solution, after reacting for 7 hours, product A was obtained;

[0049] (3) 5% of the poly-alkene of the product A quality, 1% of the acrylate-maleic anhydride copolymer of the A quality and A are mixed, stir evenly and obtain oil field crude oil pour point depressant.

Embodiment 3

[0051] (1) First mix 324.5g of octadecyl acrylate, 83.6g of 2-perfluorohexyl ethyl acrylate, and 705.8g of benzene (wherein the ratio of stearyl acrylate to perfluorohexyl ethyl acrylate is 5:1 ), warming up to 70°C, stirring for 1.5h;

[0052] (2) Add 26.1g of styrene (the ratio of octadecyl acrylate to styrene is 4:1), turn on the nitrogen protection, raise the temperature to 110°C, and drop diesel oil containing 1.4g of benzoyl peroxide solution, after reacting for 10 hours, product A was obtained;

[0053] (3) 2% poly-alkene of product A quality, 4% methacrylate-maleic anhydride copolymer of A quality are mixed with A, stir evenly and obtain oil field crude oil pour point depressant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com