Preparation method of passiflora edulis powder

A technology of passion fruit and passion fruit, which is applied in the field of preparation of passion fruit powder, can solve the problems of poor sensory quality of passion fruit powder, large loss of nutrition and aroma components, color difference, etc., to overcome high sugar content , easy to operate, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) screen out the whole fruit of purple passion fruit without damage, remove the skin and get the pulp, separate the fruit seeds, and obtain the deseeded passion fruit pulp after filtering;

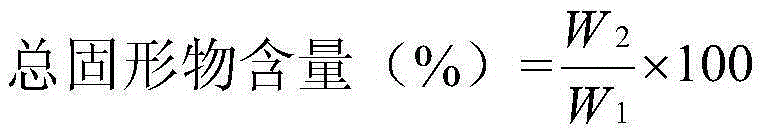

[0025] (2) Carry out the determination of the solid content of the passion fruit pulp obtained in step (1), obtain the dry weight of the passion fruit pulp, take the dry weight of the passion fruit pulp and mix the maltodextrin according to the addition amount in Table 1 Add in the passion fruit pulp, high-speed shear homogenization in the high-speed dispersion homogenizer, speed is 10000rpm, homogenization time 4min, obtains excipient passion fruit pulp mixed solution;

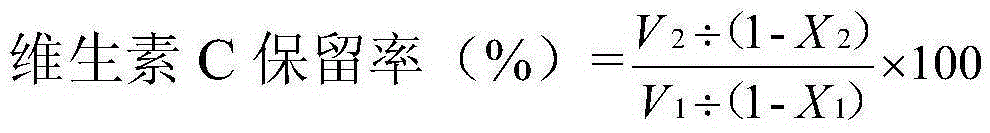

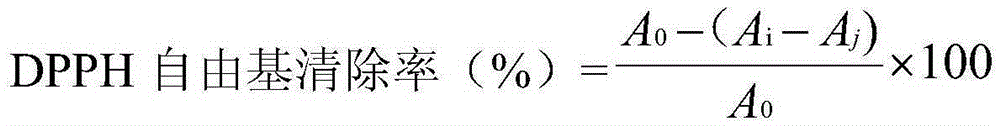

[0026] (3) inject the mixed solution of passion fruit pulp excipient obtained in step (2) into the mould, quick-freeze to -45°C, move into the vacuum drying chamber quickly after demoulding, and evacuate until the vacuum degree is 45-65Pa, Sublimation drying is carried out by heating, the sublimation drying tempe...

Embodiment 2

[0063] (1) screen out the whole fruit of purple passion fruit without damage, remove the skin and get the pulp, separate the fruit seeds, and obtain the deseeded passion fruit pulp after filtering;

[0064] (2) the passion fruit pulp obtained in step (1) is carried out to measure the solid content, draw the dry weight of the passion fruit pulp, take the dry weight of the passion fruit pulp and add gum arabic according to the addition amount in Table 2 In the passion fruit pulp, high-speed shear homogenization in the high-speed dispersion homogenizer, speed is 10000rpm, homogenization time 4min, obtains excipient passion fruit pulp mixed solution;

[0065] (3) inject the mixed solution of passion fruit pulp excipient obtained in step (2) into the mould, quick-freeze to -45°C, move into the vacuum drying chamber quickly after demoulding, and evacuate until the vacuum degree is 45-65Pa, Sublimation drying is carried out by heating, the sublimation drying temperature is 45°C, and ...

Embodiment 3

[0071] (1) screen out the whole fruit of purple passion fruit without damage, remove the skin and get the pulp, separate the fruit seeds, and obtain the deseeded passion fruit pulp after filtering;

[0072] (2) Carry out the solid content determination of the passion fruit pulp obtained in step (1), draw the dry weight of the passion fruit pulp, take the dry weight of the passion fruit pulp and separate the whey according to the addition amount in Table 3 Protein is added in passion fruit pulp, high-speed shear homogenization in high-speed dispersion homogenizer, speed is 10000rpm, homogenization time 4min, obtains excipient passion fruit pulp mixed liquid;

[0073] (3) inject the mixed solution of passion fruit pulp excipient obtained in step (2) into the mould, quick-freeze to -45°C, move into the vacuum drying chamber quickly after demoulding, and evacuate until the vacuum degree is 45-65Pa, Sublimation drying is carried out by heating, the sublimation drying temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com