Nano-fiber surface layer filtering material and preparation method thereof

A nanofiber layer and filter material technology, which is applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problem of poor bonding strength between glass fiber filter paper and nanofibers, difficult promotion of nanofiber surface filter materials, and glass fiber filter paper Weak surface adhesion and other problems, to achieve the effect of improving the bonding effect, improving the mechanical strength, and improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

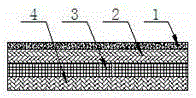

[0022] A nanofiber surface filter material described in this embodiment includes: a composite filter layer and a nanofiber layer 1; the composite filter layer includes a surface layer 2, a base cloth layer 3 and a bottom layer 4, and the base cloth layer 3 is a A cross network structure, the surface layer 2 and the bottom layer 4 are a network structure formed by one or more fibers entangled in disorder, and the surface layer 2 and the bottom layer 4 are respectively attached to the base fabric layer 3, the surface layer 2, the base fabric layer 3 and the bottom layer 4 are hooked together by needle punching; the surface layer 2 is attached with the nanofiber layer 1, the nanofiber layer 1 and the The base fabric layer 3 is attached to both sides of the surface layer 2 respectively, and the nanofiber layer 1 is composed of electrospun fibers with a diameter of 100-200 microns, and the manufacturing materials of the electrospun fibers are polyphenylene sulfide, One or more of p...

specific Embodiment 2

[0028] The structure of a nanofiber surface filter material described in this embodiment is the same as that in Embodiment 1.

[0029] The preparation method of a kind of nanofiber surface filter material described in the present embodiment, comprises the following steps:

[0030] Step 1, weaving warp and weft into the base fabric layer of an ordered network structure, and entangled the surface layer and the bottom layer of a disordered network structure by carding and needle punching, and then the surface layer, the base fabric layer and the bottom layer The composite filter layer is prepared by hooking each other through acupuncture;

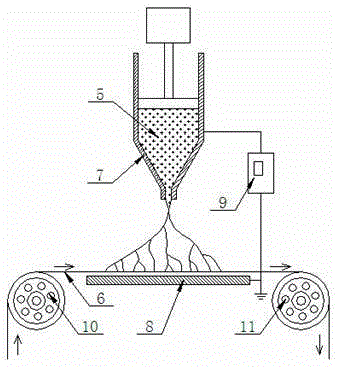

[0031] Step 2: One or more materials in polyphenylene sulfide, polyethylene terephthalate, polytetrafluoroethylene and polyimide are melted and sprayed out towards the collecting plate through the injector to form a Electrospun fibers of 100-200 microns, the nozzle of the injector and the collecting plate are both metal conductors, and a stat...

specific Embodiment 3

[0035] The structure of a nanofiber surface filter material described in this embodiment is the same as that in Embodiment 1.

[0036]The preparation method of a kind of nanofiber surface layer filter material described in this embodiment, its step 1 to step 3 are the same as specific embodiment 1, step 4, the nanofiber surface layer filter material that step 3 is made is impregnated by surface treatment liquid After drying, the surface treatment liquid includes the following components in parts by mass: 40 parts of polytetrafluoroethylene emulsion with a solid content of 60-70%, 5 parts of isopropanol, 2 parts of triacetin, benzyl 5 parts of silicone oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com