Preparation method of feruloyl esterase enzyme-fermented feed and application thereof

A technology of ferulic acid esterase and fermented feed, which is applied in application, animal feed, animal feed, etc., can solve the problems of poor growth of poultry and livestock, poor feed utilization rate, and restrictions on wide application, so as to increase the average daily feed intake , flavor improvement, and the effect of increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

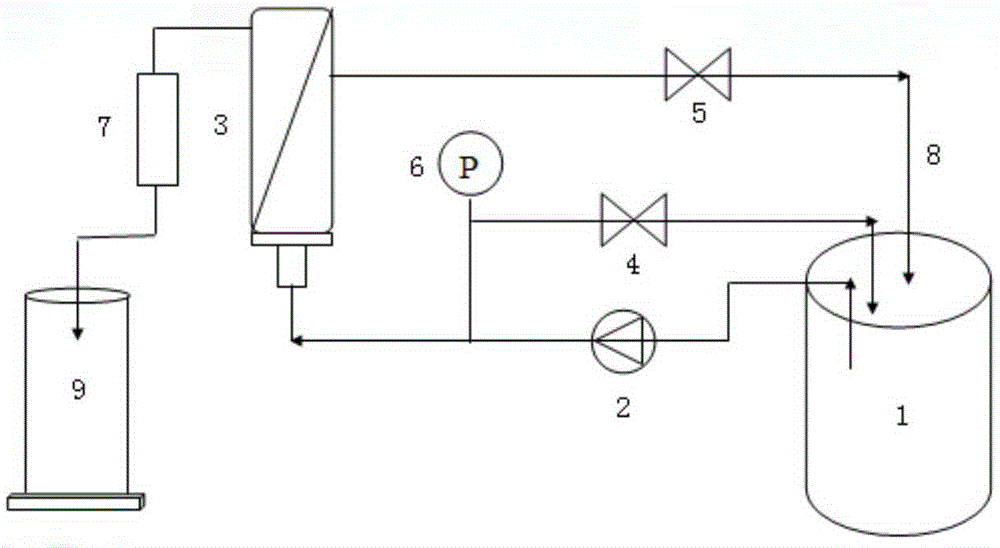

Method used

Image

Examples

Embodiment 1

[0031] A ferulic acid esterase enzymatic fermented feed, the enzymatic fermented feed is obtained from ferulic acid esterase and a starter fermented feed raw material at normal temperature, the feed raw material is calculated in parts by mass, including: corn 26 parts of protein feed, 12 parts of stipe, 16 parts of chaff powder, 11 parts of palm kernel meal, 5 parts of guar soybean meal, 5 parts of corn flour, 0.3 part of molasses, and 24.7 parts of water; The enzyme activity of ferulic acid esterase is added in a formula ratio of 8 U / g to the weight of the stipe in the feed raw material; the mass ratio of the starter is 0.1%. Its preparation method is as follows:

[0032] 1) Aspergillus niger (Aspergillus niger) is inserted into the fermentation medium according to the inoculum size of 10%, and the fermentation medium includes: 19.4 parts of bran, 19.4 parts of subflour, 0.58 part of ammonium sulfate, magnesium sulfate 2.42 parts, 58.2 parts of water; after culturing at 33°C...

Embodiment 2

[0038]The present invention also provides a solid-state fermentation medium for ferulic acid esterase, the fermentation medium comprises, in parts by mass: 16-20 parts of bran, 18-20 parts of subflour, 0.4-0.6 parts of ammonium sulfate 2.3-2.5 parts of magnesium sulfate, 45-59 parts of water.

[0039] In this embodiment, the fermentation medium includes, by mass parts, 19.4 parts of bran, 19.4 parts of wheat flour, 0.58 parts of ammonium sulfate, 2.42 parts of magnesium sulfate, and 58.2 parts of water, 100 parts in total.

[0040] In this example, all components except water are expressed in parts by mass of dry matter.

[0041] In the process of solid-state fermentation of Aspergillus niger, bran and subflour act as the carbon source for microbial growth and metabolism. The structure of bran is relatively loose, with large pores and strong hydraulic system, which can provide air and water for the growth of Aspergillus niger. At the same time, the starch content in the secon...

experiment example 1

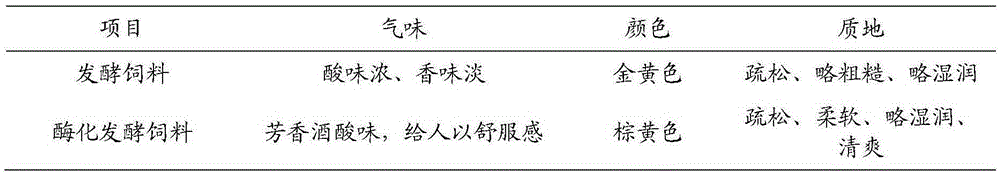

[0042] Experimental example 1 The influence of the ferulic acid esterase enzymatic fermented feed of the embodiment of the present invention 1 on three yuan pigs

[0043] 1. Experimental method

[0044] 1) Experimental animal feed

[0045] Group A is the basal feed group, i.e. common commercially available basal rations;

[0046] Group B is a fermented feed group, that is, a basal diet mixed with 12% fermented feed; compared with the enzymatic fermented feed of Example 1, except that ferulic acid esterase is not contained, all the other components are the same Its preparation method is as follows: according to the ratio of 0.1% according to mass ratio, feed starter is added in the feed raw material, and described feed raw material counts by mass parts, comprises: 26 parts of zein feedstuffs, 12 parts of stipe, 16 parts of chaff powder 11 parts of palm kernel meal, 5 parts of guar soybean meal, 5 parts of corn flour, 0.3 part of molasses, 24.7 parts of water; mix well, and us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com